The crankshaft position sensor is important for a vehicle’s engine management system But what happens if this sensor fails or is missing altogether?

Can a car still operate without it? This is a common question among car owners and mechanics.

In this article, we’ll explore whether a car run without a crankshaft position sensor or not.

Can a car run without a crankshaft position sensor?

A car cannot run without a crankshaft position sensor. The crankshaft position sensor can detect the position and speed of the engine. Without this information, the engine’s computer cannot properly operate the engine, and the car will likely not start or run properly.

The impact of a faulty or missing sensor may vary depending on the specific engine and its design.

Symptoms of a faulty crankshaft position sensor

A faulty or failing crankshaft position sensor can cause various problems in an engine and exhibits the following symptoms:

Engine stalling or misfiring:

The crankshaft position sensor is the cause of providing the engine control module (ECM).

It can send incorrect or erratic signals to the ECM, which can cause the engine to stall or misfire.

Difficulty starting or no start:

If the crankshaft position sensor is faultily failed, it prevents the engine from starting altogether.

The ECM relies on accurate signals from the sensor to determine when to inject fuel and when to ignite the spark plugs.

Reduced power and acceleration:

A faulty or failing crankshaft position sensor causes the engine runs poorly, which can result in reduced power and acceleration.

As the engine is not receiving the correct signals from the sensor and ignition timing properly.

Poor fuel economy:

If the engine is not running efficiently, it may have poor fuel economy as the engine burns more fuel than necessary due to incorrect fuel and ignition timing.

Illuminated check engine light:

A faulty crankshaft position sensor can trigger the check engine light to illuminate on the dashboard. The ECM detects incorrect or erratic signals from the sensor.

Effects of a missing or faulty sensor

A faulty sensor has a variety of effects on a vehicle. Here are some common effects of a missing or faulty sensor:

Poor engine performance:

Many sensors are crucial to the engine’s performance like the oxygen sensor, mass airflow sensor, and throttle position sensor. A faulty sensor cause the engine to run poorly.

Reduced fuel economy:

Sensors such as the oxygen sensor, fuel pressure sensor, and mass airflow sensor are responsible for providing the engine control module.

A missing or faulty sensor can cause the engine to run rich or lean, which can result in reduced fuel economy.

Increased emissions:

A missing sensor can also cause the vehicle to produce more emissions than it should.

For example, a missing or faulty oxygen sensor can cause the engine to run rich, which can result in increased emissions of carbon monoxide and hydrocarbons.

Safety issues:

Some sensors are crucial to the vehicle’s safety systems, such as the ABS sensor, traction control sensor, and airbag sensor.

A missing or faulty sensor can cause these systems to malfunction or not work at all, which can compromise the vehicle’s safety.

Transmission problems:

The transmission relies on several sensors to operate properly, such as the vehicle speed sensor, and throttle position sensor, and transmission fluid temperature sensor.

It can cause the transmission to shift improperly, slip, or fail completely.

Can a car still start without a crankshaft position sensor?

A car may still start without a crankshaft position sensor, but it is not recommended to drive the vehicle in this condition as it can cause further damage. Here are some issues to consider:

No signal to the ECM:

Without this signal, the ECM may not know when to inject fuel or ignite the spark plugs, which can prevent the engine from starting.

Limited functionality:

Some vehicles may have a backup mode that allows the engine to start and run, but with limited functionality.

This backup mode is designed to get the vehicle to a repair shop, and not for normal driving.

Engine running rough:

If the engine does start without a crankshaft position sensor, it may run rough and exhibit symptoms such as misfires, hesitation, and reduced power and acceleration.

The ECM is unable to adjust fuel and ignition timing properly without accurate signals from the sensor.

Increased risk of further damage:

Driving a vehicle without a crankshaft position sensor can cause further damage to the engine, as it can result in incorrect fuel and ignition timing.

Can A Car Still Drive Without A Crankshaft Position Sensor?

The answer is no, while a car may still be able to drive without a crankshaft position sensor. Here are some important subpoints to consider:

Reduced engine performance:

The engine’s computer cannot accurately determine the position and speed of the crankshaft, which can result in reduced engine performance and power.

Increased emissions:

A missing or faulty crankshaft position sensor can cause the engine to produce higher emissions, which can not meet environmental standards.

Risk of damage to other engine components:

The engine will not work properly due to some risks and damage, like the catalytic converter or oxygen sensors.

Difficulty starting or failure to start:

The crankshaft position sensor is also responsible for providing information to the engine’s computer to assist with starting the engine.

Stalling or hesitation during acceleration:

A faulty crankshaft position sensor can cause the engine to stall or hesitate during acceleration of it.

Increased wear and tear on engine components:

More wear and tear can reduce the engine’s overall lifespan.

Safety risks:

A car with a faulty or missing crankshaft position sensor may not operate as intended, which can lead to safety risks for the driver, passengers, and other motorists on the road.

Can a car’s computer compensate for a missing or faulty sensor?

A car’s computer may be able to compensate for a missing or faulty crankshaft position sensor to a certain extent. Here are some key points to consider:

Limited compensation:

While the car’s computer may be able to make some adjustments to compensate for the missing or faulty sensor, the adjustments are usually limited and may not fully resolve the issue.

Increased fuel consumption:

If the car’s computer is compensating for a missing or faulty crankshaft position sensor, it may need to rely on default settings or less accurate information, which can result in increased fuel consumption.

Reduced performance:

The car’s computer may not be able to accurately control the engine’s timing and fuel delivery, which can lead to reduced engine performance and power.

Increased emissions:

A car with a missing or faulty crankshaft position sensor may produce higher emissions due to incomplete combustion or incorrect fuel delivery.

Risk of engine damage:

If the car’s computer is compensating for a missing or faulty sensor, it may not be able to prevent engine damage in the event of severe or prolonged driving.

How to fix a faulty or missing crankshaft position sensor

Fixing a faulty or missing crankshaft position sensor typically involves replacing the sensor. Here are the steps to replace a faulty crankshaft position sensor:

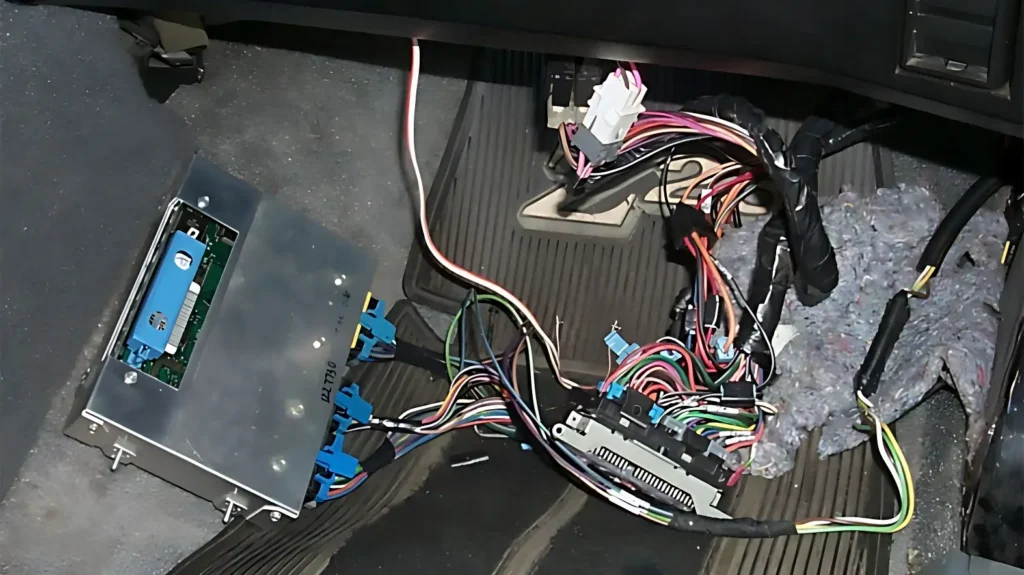

Diagnose the problem:

Before replacing the sensor, diagnose the problem of the sensor. This is done using a scan tool that reads the codes stored in the engine control module (ECM).

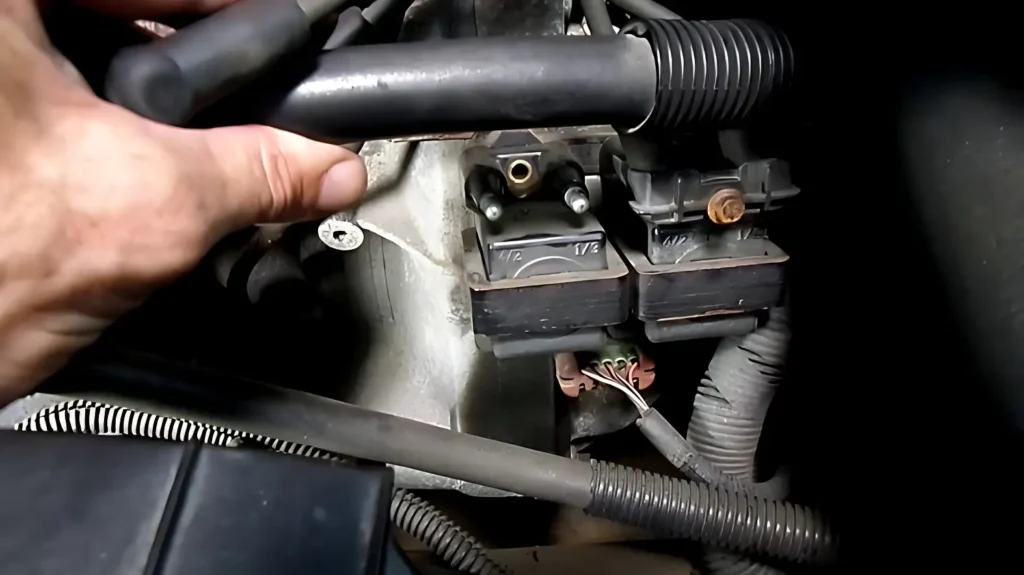

Locate the sensor:

The location of the crankshaft position sensor depends on the identification of the vehicle, located near the crankshaft pulley or flywheel.

Remove the old sensor:

To remove the old sensor, first disconnect the electrical connector and then remove any retaining bolts or clips.

Some sensors may require special tools or techniques to remove, so refer to the manufacturer’s instructions.

Install the new sensor:

Install the new sensor in the same location as the old sensor, and secure it with any retaining bolts or clips. Be sure to reconnect the electrical connector.

Clear any codes:

After installing the new sensor, clear any codes stored in the ECM using a scan tool.

This will ensure the ECM’s importance, and the new sensor can properly adjust fuel and ignition timing.

Test the vehicle:

Test the vehicle to know the new sensor is working properly. Start the engine and check for any warning lights or abnormal symptoms.

FAQs

How Important Is The Crankshaft Position Sensor To The Overall Function Of The Engine?

The crankshaft position sensor is a crucial component of the engine’s control system.

Without it, the engine may not start, or may run poorly, and it can cause damage to other engine components.

Can A Car’s Computer Compensate For A Missing Or Faulty Crankshaft Position Sensor?

A car’s computer may be able to compensate for a missing or faulty crankshaft position sensor to a certain extent.

It can depend on the specific identification of the vehicle.

Is It Safe To Drive A Car With A Faulty Crankshaft Position Sensor?

Driving a car with a faulty crankshaft position sensor is not recommended regarding some damage issues to other engine components and may break down or accident.

How Can A Faulty Crankshaft Position Sensor Be Diagnosed And Repaired?

A mechanic can diagnose a faulty crankshaft position sensor by using a scan tool to read the car’s computer codes, or by testing the sensor directly.

The sensor can typically be replaced and calibrated to restore proper engine function.

Conclusion

It is not recommended to drive the vehicle to start and run without a crankshaft position sensor.

The ECM may not be able to adjust fuel and ignition timing properly without correct information.

If a crankshaft position sensor is faulty or missing, replaced it as soon as possible so that the vehicle can run smoothly and reliably.