Are you looking to give your LS engine a performance boost with a cam swap, but don’t want to go through the hassle of removing the heads?

Well, you’re in luck! In this post, we’ll guide you through the process of doing an LS cam swap without removing the heads.

With the right tools and knowledge, you can get the job done efficiently and effectively. Let’s dive in!

Can You Perform An LS Cam Swap Without Removing Heads?

Yes, it is possible to perform an LS cam swap without removing the heads by using a special tool to compress the valve springs and remove the camshaft. However, this method may not work for all LS engines and can still be a challenging process.

Necessary Tools and Materials for LS Cam Swap Without Removing Heads

Tools Required

Camshaft holding tool: This tool holds the camshaft in place while you remove or install it.

Lifter retainer tool: This tool holds the lifters in place while you remove or install the camshaft.

Valve spring compressor: This tool compresses the valve springs so you can remove and replace them.

Camshaft degree wheel: This tool measures the degree of the camshaft’s rotation.

Materials Required

Camshaft: This is the heart of your engine’s performance and will require some research to choose the right one for your specific build.

Valve springs: Upgraded valve springs may be necessary to ensure the new camshaft’s operation.

Pushrods: Pushrods may need to be replaced or adjusted depending on the new camshaft’s lift and duration.

Camshaft bearings: These may need to be replaced depending on their condition.

Step-by-Step Guide to Performing an LS Cam Swap Without Removing Heads

Here’s a step-by-step guide to help you through the process:

Step 1: Prepare the Vehicle

Before you start, it’s essential to prepare your vehicle for the cam swap.

Park the vehicle on a level surface, apply the parking brake, and disconnect the battery to avoid any electrical mishaps.

Remove any components blocking access to the engine, such as the air intake system, battery, or engine covers.

Step 2: Drain the Coolant

To avoid coolant spills and potential damage to the engine, open the radiator drain plug and allow the coolant to drain into a suitable container.

Be sure to dispose of the coolant properly, as it can be harmful to the environment and animals.

Step 3: Remove the Accessories

To access the camshaft, you’ll need to remove any components attached to the front of the engine, such as the accessory drive belt, power steering pump, A/C compressor, and alternator.

Each component will have specific bolts and connectors that will need to be removed before you can take it off the engine.

Step 4: Remove the valve covers:

Once you have drained the coolant and removed the accessories, it’s time to remove the valve covers.

The valve covers to protect the rocker arms and pushrods. Use a socket wrench to loosen the bolts and lift the valve cover off the engine.

Set the valve cover aside, making sure to keep it in a clean and safe location.

Step 5: Remove the rocker arms and pushrods:

With the valve covers removed, you can access the rocker arms and pushrods.

You will need to remove them in order to access the camshaft. Start by loosening the rocker arm bolts and removing the rocker’s arms.

Then, carefully lift the pushrods out of the engine, making sure to keep them in order so that they can be reinstalled in the same location.

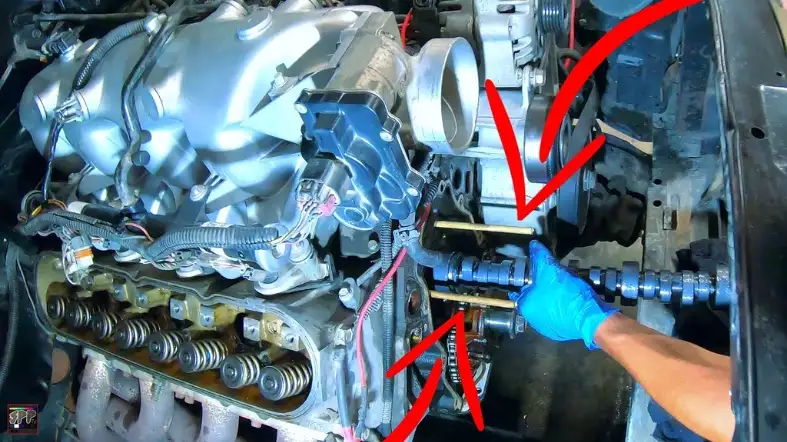

Step 6: Remove the old camshaft:

With the rocker arms and pushrods removed, you can now access the camshaft.

Remove the bolts holding the camshaft gear in place and slide the gear off the camshaft.

Then, carefully remove the camshaft from the engine block. This may require some wiggling and maneuvering to get the camshaft out.

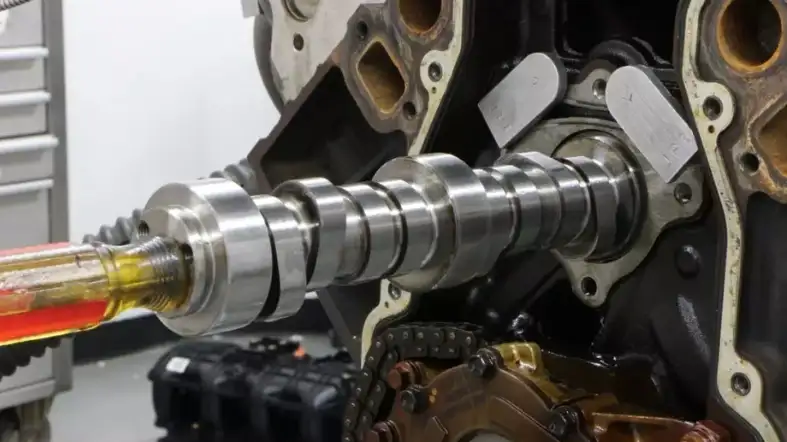

Step 7: Install the new camshaft:

Insert the new camshaft into the engine block and rotate it until it lines up with the camshaft gear.

Slide the gear onto the camshaft and tighten the bolts to the manufacturer’s specifications.

Make sure that the camshaft is installed correctly and that it’s not binding or rubbing on any other engine components.

Step 8: Reinstall The Pushrods And Rocker’s Arms:

With the new camshaft installed, it’s time to reinstall the pushrods and rocker arms in their original locations.

Carefully slide the pushrods back into the engine, making sure that they are properly seated.

Then, reinstall the rocker’s arms and tighten the bolts to the manufacturer’s specifications.

Step 9: Adjust the valve lash:

Once the pushrods and rocker arms are reinstalled, you will need to adjust the valve lash.

Follow the manufacturer’s instructions for adjusting the valve lash.

This step is crucial to ensure that the valves open and close properly and that the engine runs smoothly.

Step 10: Reinstall the valve covers:

With the valve lash adjusted, it’s time to reinstall the valve covers.

Make sure that the valve cover gaskets are clean and in good condition.

Then, carefully place the valve covers back on the engine and tighten the bolts to the manufacturer’s specifications.

Step 11: Reinstall the accessories:

Reinstall the accessories that were removed in step 3.

This includes the power steering pump, A/C compressor, and alternator.

Make sure that all components are properly connected and that any belts or hoses are tightened to the manufacturer’s specifications.

Step 12: Refill the coolant:

Refill the radiator with coolant and run the engine to check for any leaks.

Make sure that the engine is running smoothly and that all components are working properly.

If you notice any issues, address them before driving the vehicle.

Factors to Consider Before Performing an LS Cam Swap Without Removing Heads

Here are some key factors to keep in mind:

Choosing the Right Cam

Before swapping your LS engine’s camshaft, it’s crucial to select the right one for your vehicle’s application.

There are many different options available, each with its own set of characteristics and specifications.

For example, the Stage IV camshaft is best suited for highly modified 6.0-liter or larger applications with manual transmissions or automatic cars with a 3,000-plus stall converter.

Consider your vehicle’s intended use and consult with an expert if you’re unsure which camshaft is right for you.

Lifters and Rockers

To perform an LS cam swap without removing the heads, you’ll need to be able to lift the camshaft out of the engine block.

This can be accomplished by using dowels, magnets, or other methods to hold the lifters in place while you remove the camshaft.

However, it’s important to note that this method may not work for engines with worn lifters or rocker’s arms.

Timing Components

When removing the camshaft, it’s important to pay close attention to the timing components.

You’ll need to remove the cam gear and chain. Also, ensure that the timing marks are properly aligned before reinstalling the new camshaft.

Make sure to inspect these components for wear or damage before reassembling the engine.

Valve Springs

Depending on the camshaft you choose, you may need to upgrade your engine’s valve springs.

High-lift camshafts can cause the valve springs to coil bind, which can lead to engine damage.

If you’re unsure whether your engine’s valve springs are up to the task, consult with an expert before proceeding with the cam swap.

Other Considerations

In addition to the factors mentioned above, there are a few other things to keep in mind before attempting an LS cam swap without removing the heads.

For example, you’ll need to drain the coolant from the engine block and remove the water pump and harmonic balancer.

Additionally, you may need to purchase or fabricate specialized tools to help with the cam swap process.

Tips and Tricks for a Successful LS Cam Swap Without Removing Heads

Here are some tips and tricks to make your cam swap a success:

Use dowel pins:

Dowel pins are a great tool to help keep the lifters in place when removing the camshaft.

Simply insert the dowel pins into the lifter bores before removing the camshaft.

This will keep the lifters from falling into the engine block and potentially causing damage.

Once the cam is out, the dowel pins can be removed and the new cam can be installed.

Use steel brake line:

Another useful tool for a cam swap without removing the heads is some 5/16 steel brake lines from a parts store.

Cut two pieces measuring about 28″ and pound the lines into a slight “D” shape. Lubricate with motor oil and slide into the two front lifter bores.

This will help keep the lifters from dropping out of place while swapping the cam.

Get a buddy to help:

A cam swap can be a daunting task for one person, so it’s always a good idea to have a buddy help out.

They can hold tools, provide assistance when needed, and help keep things organized.

Use a box end wrench:

To hold the camshaft in place while installing or removing it, try bolting a box end wrench to the end of the cam.

Guide the cam in carefully with one hand on the fastened end and the other on the wrench.

Be careful:

When performing a cam swap without removing the heads, it’s important to be extra careful.

Make sure to take your time and follow all the necessary steps to avoid damaging your engine.

Common Challenges Faced When Swapping LS Cam Without Removing Heads

Here are some Common Issues and Solutions during LS Cam Swap Without Removing Heads:

Removing Lifters and Pushrods

Removing lifters and pushrods can be tricky without removing the cylinder heads. One solution is to use 5/16 steel brake lines from a parts store.

Then cut them into two pieces measuring about 28 inches, pound them into a slight “D” shape, lube them with motor oil, and slide them into the lifter bores.

Another solution is to use lifter dowel rods to hold up the lifters while the camshaft is removed.

As one user suggested, it is important to ensure that all lifters are at the top before removing the camshaft.

Aligning Camshaft

Aligning the camshaft can be challenging without removing the heads.

One user suggested using a box-end wrench bolted to the end of the camshaft for leverage and gently guiding it into place.

Another user recommended using light pressure on the dowel to ensure the dowel slides straight back.

It is important to ensure that the camshaft is properly aligned to prevent engine damage.

Valve Spring Pressure

When swapping camshafts, it is important to consider valve spring pressure.

Some camshafts require higher spring pressure than the stock camshaft, which can result in valve float if not addressed.

One user recommended using a Stage I camshaft designed for mild builds and can be used with basic LS6-style springs and will make great power with 15 psi or less boost.

Another user recommended using the Texas Speed Torquer v2 cam or the Futral F13/F14 and upgrading to higher pressure valve springs.

Accessing Camshaft

Accessing the camshaft can be difficult without removing the cylinder heads.

One solution is to remove the water pump and harmonic balancer.

Then remove the valve covers and all 16 rockers and pushrods to make spinning the camshaft easier.

Another user suggested removing the lifters and pushrods and fishing them up into the valley and through the heads.

FAQs

Is It Recommended To Remove The Heads During A 5.3 LS Cam Swap?

It’s recommended to remove the heads during a 5.3 LS cam swap if there is wear on the pushrod tips and rocker’s arms or if you plan to change the lifters.

Otherwise, it’s possible to swap the camshaft without removing the heads.

What Are The Steps To Perform An LS Cam Swap Without Removing The Heads?

To perform an LS cam swap without removing the heads, follow these steps: drain the coolant, remove the water pump and harmonic balancer, remove the old camshaft, install the new camshaft, adjust the valve lash, and check the timing belt or chain tensioner before buttoning everything back up.

What Tools Do I Need For An LS Cam Swap?

To secure lifters in place during an LS cam swap, you will need dedicated tools, although they may no longer be available.

Other methods involve using wooden dowels or a pen magnet.

How Long Does It Take To Perform An LS Cam Swap?

On average, it takes about four hours to perform an LS cam swap.

Conclusion

If you want to do an LS cam swap without removing the heads, it is possible, but there are some things to consider.

Some sources say it can be done using dowel rods or magnets to hold the lifters in place while swapping the cam.

However, even if you can swap the cam without pulling the heads, it’s important to check for wear on the lifters, pushrods, and rocker’s arms before proceeding.

LS engines can handle larger cams than older engines, so a cam swap can be an effective way to increase performance.