At times, replacing a damaged axle or doing some maintenance work can be expensive and time-consuming.

But if you know how to remove a stuck rear axle shaft, it’s not as hard as it looks.

Whether you need to replace a defective part or just want to perform regular upkeep, knowing how to take out an immovable rear axle shaft will save your wallet from taking too much of a hit.

With these helpful hints at your disposal, there won’t be any roadblocks stopping you from getting back behind the wheel soon.

How To Remove Stuck Rear Axle Shaft?

Here are the steps you can follow to remove a stuck rear axle shaft:

Prepare the vehicle:

Put the car on jack stands, and remove the wheels and the brake callipers from the axle you are working on.

Remove the differential cover:

This will allow you to access the differential carrier.

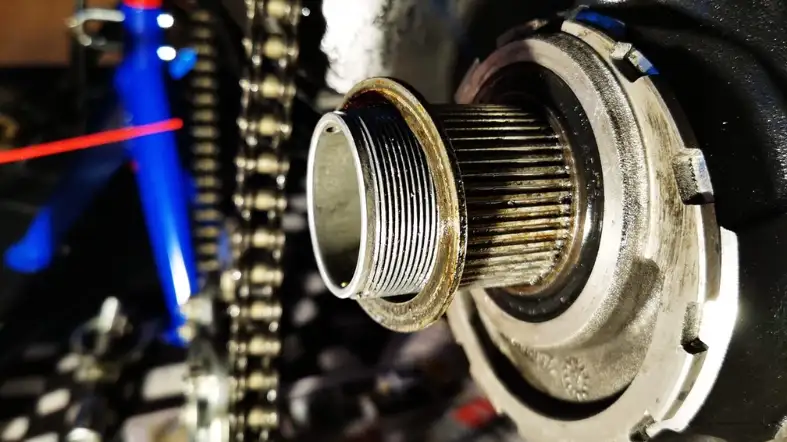

Remove the differential pinion shaft:

This is typically held in place by a bolt. Once you remove it, the pinion gears will move freely.

Push the axle shaft inward:

This will allow you to access the c-clip that holds the axle in place.

Remove the c-clip:

Use a pair of pliers to remove the c-clip from the end of the axle shaft. You may need to wiggle the axle shaft to get the c-clip to release.

Pull the axle shaft out:

Once the c-clip is removed, you should be able to pull the axle shaft out of the housing. If it’s stuck, you can use a slide hammer or pry bar to help loosen it.

Clean the area:

Before re-installing the axle shaft, make sure the area is clean and free of debris. You can use a wire brush or sandpaper to clean the surface.

Re-install the axle shaft:

Slide the axle shaft back into the housing, and re-install the c-clip.

Re-install the differential pinion shaft:

Once the axle shaft is back in place, re-install the differential pinion shaft and tighten the bolt.

Re-install the differential cover, wheels and brake callipers:

Finally, re-install the differential cover and the other components you removed earlier.

Tips for Using Heat to Loosen a Stuck Axle Shaft

Here are some tips for using heat to loosen a stuck axle shaft:

Choose the Right Heat Source:

You could grab a propane torch or an acetylene one; alternatively, consider an induction heater or even just a trusty heat gun.

For example: if you’re working with high temperatures then maybe go for the gas-powered option instead of trying to use electricity as this can be dangerous and potentially damaging.

Whatever method you pick though – always follow safety instructions carefully!

Heat the Area Around the Shaft:

Rather than heating the shaft directly, heat the area around the shaft to expand the metal and loosen the grip of any rust or corrosion. This will help prevent damage to the shaft itself.

Heat Gradually:

Heat the area gradually and evenly to avoid causing any warping or cracking of the metal.

This can be accomplished by moving the heat source around the area to distribute the heat.

Avoid Overheating:

Overheating the metal can cause it to weaken or even crack, which can make the problem worse.

Monitor the temperature of the metal to ensure you do not overheat it.

Use Protective Gear:

When working with heat, it is important to protect yourself. Wear appropriate personal protective equipment, including gloves, goggles, and clothing that covers your skin.

Be Patient:

Heating a stuck axle shaft can be a time-consuming process. Be patient and do not rush the job, as this can lead to mistakes or additional damage.

Use Penetrating Oil:

Prior to heating the area, apply penetrating oil to help break up any rust or corrosion. This can help make the heating process more effective.

Tap the Shaft:

After heating the area, tap the end of the shaft gently with a hammer to help break it free from the hub.

Rotate the Shaft:

If the shaft is still stuck, try rotating it back and forth to help loosen it. Apply more heat as needed.

Apply Pressure:

If all else fails, you can apply pressure to the end of the shaft using a press or a slide hammer to try to remove it. Again, be patient and work slowly to avoid causing damage.

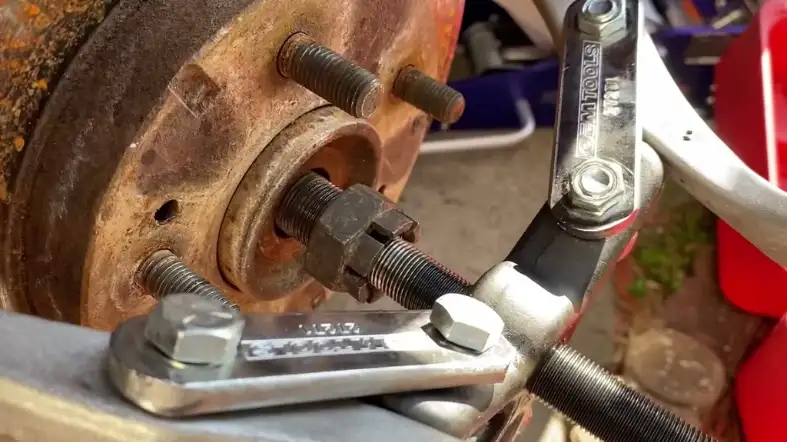

Use a Puller:

A puller can be used to apply even pressure to the end of the axle shaft and help remove it from the hub.

Use a Hydraulic Press:

A hydraulic press can be used to apply force evenly to the shaft and hub to help separate them.

Try Vibration:

Vibration can help loosen rust and corrosion. Use a hammer or a vibrating tool to loosen the stuck shaft.

Soak in Hot Water:

Soaking the area around the shaft in hot water can help to expand the metal and break up any rust or corrosion.

Use Dry Ice:

Applying dry ice to the hub can cause it to contract, which may help loosen the grip of any rust or corrosion on the shaft.

Use a Cutting Torch:

If all else fails, a cutting torch can be used to cut through the shaft and remove it from the hub.

However, this should be a last resort, as it can be dangerous and may damage the hub.

Apply Shock:

Applying a sudden shock, such as hitting the end of the shaft with a hammer, can help to break up any rust or corrosion and loosen the shaft.

Use a Nut and Bolt:

Place a nut and bolt on the end of the shaft and tighten it until it pushes the shaft out of the hub.

Use a Bearing Puller:

A bearing puller can be used to apply force to the end of the shaft and remove it from the hub.

How to Apply Penetrating Oil for Maximum Effectiveness?

Choose the Right Type of Penetrating Oil

The first step in applying penetrating oil for maximum effectiveness is to choose the right type of oil for your needs. Some common types of penetrating oils include:

- – Linseed oil: A natural oil derived from flaxseeds that is ideal for use on porous woods.

- – Tung oil: A natural oil derived from the seeds of the tung tree that is highly resistant to water and chemicals.

- – Danish oil: A mixture of linseed oil and varnish that provides a durable, moisture-resistant finish.

- – Teak oil: A blend of natural oils that is ideal for use on outdoor furniture and decking.

When selecting a penetrating oil, consider the type of wood you are working with, the level of durability and water resistance required, and the desired finish.

Prepare the Surface

Before applying the penetrating oil, it is important to properly prepare the surface.

This may involve sanding the wood to remove any existing finish or rough spots and wiping it down with a clean cloth to remove any dust or debris.

If the wood is particularly dirty or stained, you may need a wood cleaner or stain remover before applying the oil.

Apply the Penetrating Oil

To apply the penetrating oil, use a clean, lint-free cloth or brush to spread the oil evenly over the surface of the wood.

Be sure to apply the oil in the direction of the grain and work it into the wood as much as possible.

Allow the Oil to Dry

After applying the penetrating oil, allow it to dry completely before using or handling the wood.

This may take several hours or even overnight. Varying types of oil and environmental conditions can affect this process, so plan accordingly.

Make sure you have all bases covered and get your project done right—no need to rush it.

Maintain the Finish

To maintain the finish and effectiveness of the penetrating oil, it is important to take proper care of the wood.

This may involve periodic cleaning and reapplication of the oil, as well as avoiding exposure to excessive moisture or extreme temperatures.

Common Mistakes to Avoid When Removing a Stuck Axle Shaft

Here are some common mistakes to avoid when removing a stuck axle shaft:

Using excessive force:

Pulling or hitting the stuck axle shaft with excessive force can cause damage to the surrounding components, such as bearings or seals, leading to costly repairs.

Not using the correct tools:

Using the wrong tools can also cause damage or make the job more difficult. Make sure to use the appropriate tools for the job, such as a slide hammer or axle puller.

Not properly supporting the vehicle:

Make sure to properly support the vehicle on jack stands or a lift before attempting to remove the stuck axle shaft.

Ignoring safety precautions:

Removing a stuck axle shaft can be dangerous, so it’s important to take the proper safety precautions, such as wearing safety goggles and gloves and making sure the vehicle is securely supported.

Not applying enough heat:

Heat can be a useful tool for loosening a stuck axle shaft, but it’s important to apply enough heat to make a difference.

Applying too little heat can be ineffective while applying too much heat can cause damage.

Not giving enough time for the heat to work:

After applying heat to the stuck axle shaft, it’s important to give it enough time to work before attempting to remove it.

Rushing the process can result in further damage or make the job more difficult.

Using the wrong lubricant:

Any negligence in this regard may cost you time and money down the road; so don’t let a careless mistake ruin all your hard work.

Make sure to use the appropriate lubricant for the job, such as penetrating oil or grease.

Not properly cleaning the area:

Before attempting to remove the stuck axle shaft, make sure to properly clean the area around it to avoid getting dirt or debris inside the differential or transmission.

Not properly identifying the cause of the problem:

A stuck axle shaft can have several causes, such as a damaged bearing or seal. It’s important to properly identify the cause of the problem to avoid further damage or repairs.

Giving up too soon:

Removing a stuck axle shaft can be a difficult and time-consuming job, but it’s important to stay patient and persistent.

Giving up too soon can result in unnecessary damage or costly repairs.

Frequently Asked Question

Can I Remove A Stuck Axle Shaft Without Using Heat?

Yes, it is possible to remove a stuck axle shaft without using heat.

Some methods include using penetrating oil, a slide hammer, or a hydraulic press.

However, using heat can often make the process easier and quicker.

Is It Safe To Use Heat To Remove A Stuck Axle Shaft?

Yes, it is safe to use heat to remove a stuck axle shaft as long as you take proper precautions.

Wear heat-resistant gloves and eye protection, and make sure there are no flammable materials nearby.

Also, avoid overheating the shaft, as this can cause damage.

What Should I Do If The Axle Shaft Is Stuck After Heat Use?

If the axle shaft is still stuck after using heat, you may need to try a different method or seek the assistance of a professional mechanic.

Applying too much force can cause damage to the assembly or other components.

Conclusion:

Removing a stuck rear axle shaft may seem like a challenging task, but it is not impossible.

With the right tools and some patience, you can remove a stuck rear axle shaft without damaging your vehicle or yourself.

Remember to always take safety precautions, such as wearing gloves and goggles, and consult your vehicle’s manual or a professional mechanic if you are unsure about any step.