Cam phaser noise can be a nuisance for many vehicle owners, causing a loud and unsettling rattling or knocking sound.

There are several ways to quiet cam phaser noise, depending on the underlying cause.

From using high-quality engine oil to replacing faulty cam phaser components, there are steps you can take to reduce or eliminate the noise and restore a smoother, quieter ride.

In this article, we’ll explore some of the most effective methods for quieting cam phaser noise in your vehicle.

how to quiet cam phaser noise

Here’s how to quiet cam phaser noise in your vehicle.

Replace the Cam Phaser:

The cam phaser is responsible for controlling the timing of the camshaft in relation to the crankshaft.

Over time, the phaser can wear out, causing noise and other problems. If the cam phaser is the source of the noise, replacing it with a new one can help.

Use Thicker Oil:

Thicker oil can help reduce cam phaser noise by increasing oil pressure and providing better lubrication to the phaser.

Check your vehicle’s owner’s manual to determine the recommended oil viscosity for your engine.

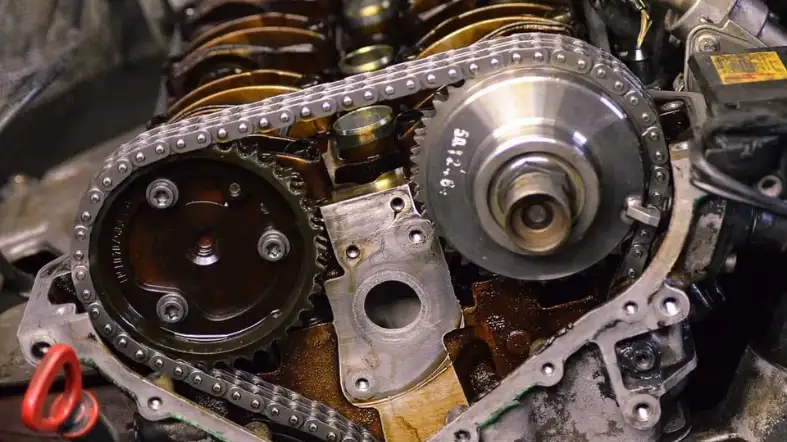

Check the Timing Chain:

A loose or worn timing chain can cause the cam phaser to make noise. If the timing chain is the issue, it will need to be replaced.

Check the Tensioner:

The timing chain tensioner keeps the timing chain tight, which helps to reduce noise. If the tensioner is worn or malfunctioning, it may need to be replaced.

Inspect the Oil Control Valve:

The oil control valve regulates oil flow to the cam phaser.

If it becomes clogged or damaged, it can cause noise. Inspect the valve and clean or replace it as necessary.

Replace the Oil Filter:

A clogged oil filter can reduce oil pressure and flow, which can cause the cam phaser to make noise. Replace the oil filter regularly to ensure proper oil flow.

Use an Additive:

Some engine oil additives claim to reduce cam phaser noise. These additives can help to reduce friction and wear in the engine, which can reduce noise.

Seek Professional Help:

If you are not comfortable working on your engine, or if you have tried these methods and still hear noise, seek the help of a professional mechanic.

They can diagnose the problem and recommend the best course of action to fix it.

Symptoms Of Cam Phaser Noise

Here are some issues describing the symptoms of cam phaser noise:

Engine ticking or knocking sound:

A common symptom of cam phaser noise is a ticking or knocking sound coming from the engine.

The sound may be more noticeable at idle or during acceleration.

Poor engine performance:

Cam phaser noise can cause the engine to run poorly, with reduced power or acceleration.

The timing of the valves can become out of sync, causing the engine to run rough or stall.

Illuminated check engine light:

In some cases, cam phaser noise can trigger the check engine light to turn on. This is often due to a sensor detecting a problem with the variable valve timing system.

Reduced fuel efficiency:

Cam phaser noise can also cause reduced fuel efficiency due to poor engine performance.

The engine may need to work harder to maintain speed or acceleration, causing it to burn more fuel.

Oil pressure warning:

Cam phaser noise can also cause low oil pressure in the engine.

This can lead to an oil pressure warning light coming on, indicating a potential issue with the engine lubrication system.

Tools and Materials Required

Replacing a camshaft and lifters typically requires a number of specialized tools and materials. Here are some of the common tools and materials that may be required:

Socket wrench set:

A comprehensive socket wrench set with a range of socket sizes is necessary for removing and tightening bolts and nuts of various sizes.

Torque wrench:

A torque wrench is essential for accurately tightening bolts and nuts to the manufacturer’s recommended torque specifications, which is important for ensuring the proper functioning of the engine.

Camshaft bearing tool:

A camshaft bearing tool is required to remove and install the camshaft bearings.

This tool ensures that the bearings are properly aligned and seated in the engine block, preventing damage to the camshaft and other engine components.

Camshaft installation tool:

A camshaft installation tool is used to properly align and install the camshaft in the engine.

This tool helps to ensure that the camshaft is installed in the correct position and properly timed with the rest of the engine.

Lifters:

Replacement lifters are necessary for the repair. Depending on the extent of the damage, it may be necessary to replace all the lifters to ensure that the engine runs smoothly and quietly.

Gasket kit:

A gasket kit may be required to replace any gaskets that are damaged or worn during the repair.

This helps to ensure that the engine is properly sealed and prevents oil leaks and other issues.

Engine oil:

Fresh engine oil is required to lubricate the camshaft and lifters during and after the repair.

It is important to use the type and grade of oil recommended by the manufacturer to ensure proper engine function.

Engine oil filter:

Replacing the oil filter is recommended when replacing the camshaft and lifters. This helps to ensure that the new components are not contaminated by old oil or debris.

Engine oil additive:

An engine oil additive designed to reduce engine noise may be used to help quiet any remaining camshaft noise after the repair is complete.

This can help to improve the performance and longevity of the engine.

Post-Repair Considerations

After replacing the camshaft and lifters, there are several post-repair considerations to keep in mind:

Break-in period:

It is important to properly break in the new camshaft and lifters by driving the vehicle gently for the first few hundred miles.

This allows the components to properly seat and reduces the risk of premature wear or failure.

Oil and filter change:

After the break-in period, it is recommended to change the engine oil and filter to remove any debris or metal particles that may have accumulated during the break-in process.

Regular oil changes:

Regular oil changes are essential for the proper functioning and longevity of the engine.

It is recommended to change the oil every 5,000-7,500 miles, or as recommended by the manufacturer.

Check for leaks:

After the repair, it is important to check for any oil leaks or other issues. This can be done by inspecting the engine and looking for any signs of oil or fluid leaks.

Listen for noise:

While some camshaft noise may be normal, it is important to listen for any unusual noises or vibrations.

If you notice any new or unusual noises, it is important to have the vehicle inspected by a professional to ensure that everything is functioning properly.

Monitor engine performance:

Keep an eye on the vehicle’s performance and check for any warning signs, such as poor acceleration or decreased fuel efficiency.

These could be indications of other issues that need to be addressed.

Preventative Measures

There are several preventative measures you can take to help prevent camshaft and lifter failure:

Regular maintenance:

Regular maintenance is essential for the proper functioning and longevity of the engine.

This includes regular oil changes, using the recommended grade and type of oil, and keeping the engine clean and free of debris.

Using high-quality parts:

When replacing parts in your engine, it is important to use high-quality, OEM, or equivalent parts.

Cheaper or lower quality parts may be more prone to failure, and can ultimately cost more in the long run.

Checking for engine warning signs:

Keep an eye out for any warning signs, such as unusual noises, vibrations, or decreased performance.

These could be indications of other issues that need to be addressed before they cause damage to the camshaft and lifters.

Avoiding excessive engine load:

Avoid overloading the engine or pushing it beyond its limits. This can put excess stress on the camshaft and lifters, leading to premature wear and failure.

Avoiding extreme temperatures:

Extreme temperatures, both hot and cold, can put stress on the engine and its components.

If possible, avoid operating the vehicle in extreme temperatures, or take steps to protect the engine from extreme temperatures.

FAQs

Can The Cam Phaser Noise Be Repaired Without Replacing The Camshaft?

It may be possible to repair the cam phasers without replacing the camshaft.

This can involve replacing the phaser solenoids or performing an engine flush to remove debris and sludge from the engine.

How Can I Tell If The Cam Phasers Need To Be Replaced?

Signs of cam phaser failure include engine noise or ticking, poor acceleration, decreased fuel efficiency, or engine misfires.

If you suspect that the cam phasers may be the issue, it is recommended to have the vehicle inspected by a professional.

Can I Fix The Cam Phaser Noise Myself?

While it is possible to repair cam phaser noise yourself, it is recommended to have the vehicle inspected by a professional.

Cam phaser replacement can be a complex and involved process, and mistakes can lead to further engine damage.

How Much Does It Cost To Fix Cam Phaser Noise?

The cost to fix cam phaser noise can vary depending on the extent of the damage and the identification of the vehicle.

Simple repairs such as replacing the solenoids or performing an engine flush may be enough, while in other cases, a full camshaft replacement may be necessary.

It is recommended to get a quote from a professional mechanic before proceeding with any repairs.

Conclusion

Cam phaser noise can be a frustrating and concerning issue for vehicle owners.

With the right tools, knowledge, and techniques, it is possible to quiet cam phaser noise and restore the proper functioning of your engine.

By following proper diagnostic procedures, using high-quality replacement parts, and taking preventative measures to reduce the risk of future issues, you can help ensure the longevity and performance of your vehicle.