When installing or replacing a camshaft in your vehicle, it is essential to properly break in new lifters on the used cam.

Breaking in the lifters helps them form a good mating surface with the camshaft and ensures optimal engine performance.

Today we will explain the importance of breaking in new lifters, and provides step-by-step instructions, and troubleshooting tips.

How To Break In New Lifters On Used Cam?

To break in new lifters on a used cam, apply a thin layer of camshaft lube on the cam lobes and bottom of the lifters, and turn the engine over little by little to inspect each lobe.

Use a shorter-ratio rocker arm during the first hour of operation before swapping.

Run the engine at 2000-2500 RPM for 15-20 minutes with new lifters and break-in additives. Do not use used lifters on a new flat tappet cam.

Preparing Process For Break In New Lifters On Used Cam

Here are the steps you can follow to prepare for a break-in:

Clean the lifters thoroughly:

Make sure that there is no dirt or debris on the lifters before installing them. You can use a solvent or brake cleaner to clean them.

Soak the lifters in oil:

Before installing the lifters, soak them in engine oil for a few hours. This will ensure that they are properly lubricated before they come into contact with the camshaft.

Use a high-quality break-in oil:

When you are installing the lifters and camshaft, use a high-quality break-in oil.

This oil is specially formulated to provide extra protection during the critical break-in period.

Follow the manufacturer’s instructions:

It’s important to follow the manufacturer’s instructions when installing new lifters on a used camshaft.

Make sure that you torque everything to the correct specifications and that you use the recommended assembly lube.

Perform a proper break-in:

After installing the lifters and camshaft, it’s important to perform a proper break-in procedure.

This typically involves running the engine at varying RPMs and loads for a certain amount of time.

Make sure that you follow the manufacturer’s recommendations for the break-in procedure.

Step-By-Step Guide For Breaking In New Lifters On Used Cam

Here step-by-step process of breaking in new lifters on a used cam with details instructions:

Step 1: Preparing the Engine

Before you start the process, you need to ensure that your engine is in good condition. Check the oil level and replace it if necessary.

It’s essential to use high-quality oil to protect your engine during the break-in process.

Also, ensure that your engine is properly lubricated to prevent any damage to the lifters.

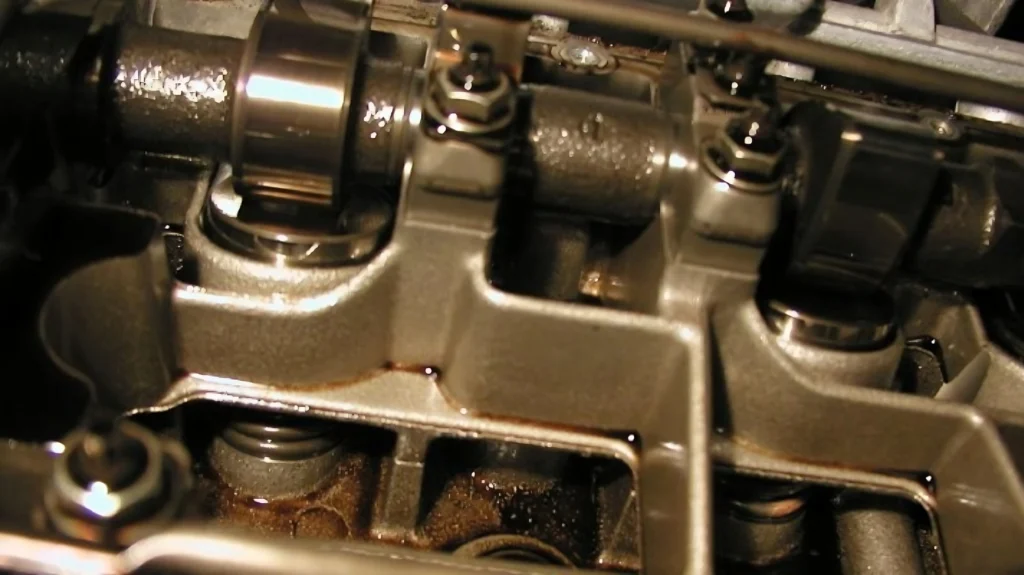

Step 2: Adjusting Valve Lash

The next step is to adjust the valve lash. The valve lash is the gap between the rocker arm and the valve stem when the lifter is on the base circle.

Adjusting the valve lash is essential to ensure proper lifter operation during the break-in process.

The recommended valve lash setting varies depending on the camshaft, so refer to the camshaft manufacturer’s instructions.

Step 3: Pre-Lubricating Lifters

Before installing new lifters, it’s crucial to pre-lubricate them. Use a high-quality assembly lube and apply it to the lifter roller, camshaft lobes, and lifter bores.

Pre-lubricating the lifters ensures that they are well-lubricated during the break-in process and helps prevent any potential damage.

Step 4: Installing New Lifters

Once you have pre-lubricated the lifters, it’s time to install them. Ensure that you install them in the correct orientation, as indicated by the manufacturer.

You should also replace any worn-out components, such as pushrods or rocker’s arms, at this stage.

Step 5: Starting the Engine

Once you have installed the new lifters, it’s time to start the engine. Start the engine and let it idle for about 20 minutes.

During this time, ensure that the oil pressure is normal, and that there are no abnormal noises coming from the engine.

Step 6: Varying Engine RPM

After idling the engine for 20 minutes, it’s time to vary the engine RPM.

You can do this by gradually increasing the engine RPM to around 2000 RPM and then decreasing it back to idle.

Repeat this process for around 30 minutes, ensuring that you vary the RPM every two minutes.

This step helps to ensure that the lifters are properly broken in and will work efficiently.

Step 6: Shutting Down the Engine

After running the engine at varying RPMs, it’s time to shut it down. It’s important to let the engine cool down for at least an hour to prevent thermal shock to the lifters.

Once cooled down, the engine oil and filter should be changed to remove any metal debris and contaminants that accumulated during the break-in process.

Note

Remember to use high-quality oil, pre-lubricate the lifters, adjust the valve lash, and vary the engine RPM during the break-in process.

The Importance of Breaking in New Lifters on Used Cam

Breaking in new lifters on a used camshaft is essential to ensure optimal engine performance.

The break-in process helps seat the lifters, allowing them to operate smoothly and reduce wear.

Without proper break-in, the lifters can wear prematurely, leading to engine damage and decreased performance.

Tips for Installing New Lifters on an Old Cam

Here are some tips to keep in mind:

Check the condition of the cam:

Before installing new lifters, inspect the camshaft for any signs of wear or damage.

Used lifters are often concave and may not spin properly on a foreign cam, leading to lobe failure. If the camshaft is damaged, it may need to be replaced.

Use assembly lube and break-in additive:

When installing new lifters, use moly assembly lube and Lucas oil break-in additive to help the lifters mate to the cam lobes.

This is especially important when breaking in an engine with a flat tappet camshaft.

Follow specific break-in procedures:

Most camshafts come with specific break-in procedures, which are critical to the performance and long life of an engine with a flat tappet cam.

If you’re not sure what the specific instructions are for your camshaft, consult the manufacturer or a professional mechanic.

Bring the engine up to 2,500 RPM or more:

During the break-in process, it’s important to immediately bring the engine up to a minimum of 2,500 RPM or more.

This is especially vital for most V8 pushrod engine camshafts, which are not designed to run at low RPMs for extended periods of time.

Consider the condition of the cam and lifters:

While some experts suggest that new lifters on a used cam may work fine, others caution against this practice, particularly if the camshaft is damaged or the lifters are collapsed.

Before installing new lifters, check the condition of both the cam and lifters to ensure they are compatible and in good condition.

Post-Break-In Maintenance

After the break-in process, it’s essential to follow proper maintenance procedures to ensure optimal engine performance.

This includes regular oil changes, checking the valve lash, and inspecting the lifters and camshaft for wear.

Troubleshooting Tips

If you experience issues during the break-in process or notice unusual engine behavior, it’s important to address them immediately.

Some common issues include excessive lifter noise, low oil pressure, and oil leaks.

These issues can be caused by an improper break-in, incorrect valve lash, or faulty lifters.

FAQss

What Is A Lifter And How Does It Work With A Cam?

A lifter is a small component that sits between the camshaft and the pushrod in an engine.

Its purpose is to transfer the motion of the camshaft to the pushrod, which then transfers it to the rocker arm and valve.

The camshaft is designed with lobes that push on the lifters, causing them to move up and down in a specific sequence, opening and closing the valves at the correct time.

Why Do I Need To Break In New Lifters On A Used Cam?

When a new lifter is installed on a used camshaft, it needs to be properly broken in to ensure that it forms a good mating surface with the camshaft.

The camshaft has already been worn to match the old lifters, and the new lifter needs to wear in to match the profile of the camshaft.

How Do I Break In New Lifters On A Used Cam?

The best way to break in new lifters on a used cam is to follow the manufacturer’s recommended procedure, which usually involves running the engine at a specific RPM for a certain amount of time with a specific type of oil.

This allows the lifters to wear in and form a good mating surface with the camshaft.

Can I Break In New Lifters On A Used Cam Without A Specific Procedure?

While it’s possible to break in new lifters on a used cam without following a specific procedure, it’s not recommended.

An improper break-in can result in poor performance, premature wear, and even failure of the engine.

How Long Does The Break-In Process Take?

The length of the break-in process can vary depending on the type of lifter and camshaft, as well as the manufacturer’s recommendations.

Some may take a few hundred miles of driving, while others may require several hours of running the engine at specific RPMs.

What Happens If I Don’t Break In New Lifters On A Used Cam?

If new lifters are not properly broken in on a used camshaft, they may not wear in properly, resulting in poor performance, premature wear, and even failure of the engine.

In some cases, the lifters may seize up, causing the camshaft to fail.

Can I Reuse Lifters On A Different Camshaft?

It’s generally not recommended to reuse lifters on a different camshaft, as they will have already worn to match the profile of the old camshaft. Reusing lifters on a different camshaft can result in poor performance, premature wear, and even failure of the engine.

Conclusion

Properly breaking in new lifters on a used cam is crucial for the longevity and performance of your engine.

By following the manufacturer’s recommended procedure, you can ensure that the new lifters wear in properly and form a good mating surface with the camshaft.

Failure to properly break in new lifters can result in poor performance, premature wear, and even engine failure.

So, take the time to properly break in your new lifters, and your engine will thank you with better performance and longevity.