If you’re experiencing issues with your GM vehicle’s engine, it could be due to a faulty crankshaft position sensor.

The good news is that performing a crankshaft position sensor relearn on your GM vehicle can often solve the problem.

In this blog post, we’ll provide you with a comprehensive guide to GM crankshaft position sensor relearn.

We’ll cover everything from the basics of what a crankshaft position sensor is to step-by-step instructions on how to perform a relearn. So, let’s dive in!

GM Crankshaft Position Sensor Relearn

Performing a relearn is a relatively straightforward process that can be done with a few simple steps.

Step 1: Prepare your vehicle for the relearn

Before you begin the relearning process, you need to ensure that your vehicle is in the proper condition.

First, make sure that your battery is fully charged and in good working condition.

If your battery is weak or dead, you may experience issues during the relearning process.

Ensure that your vehicle has a full tank of gas and that all of your accessories are turned off.

Finally, make sure that your vehicle is parked in a safe and secure location where you can work on it without interruption.

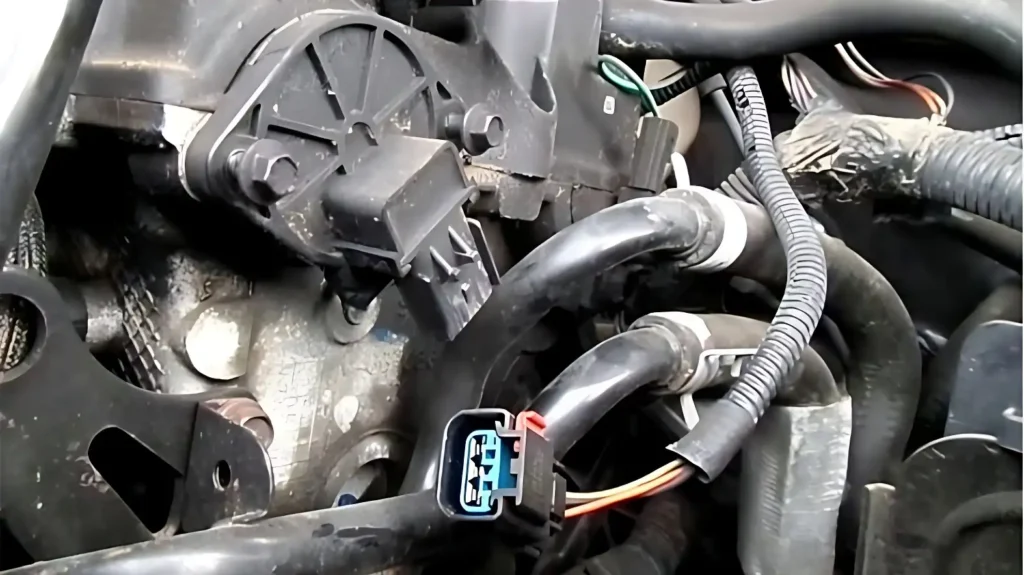

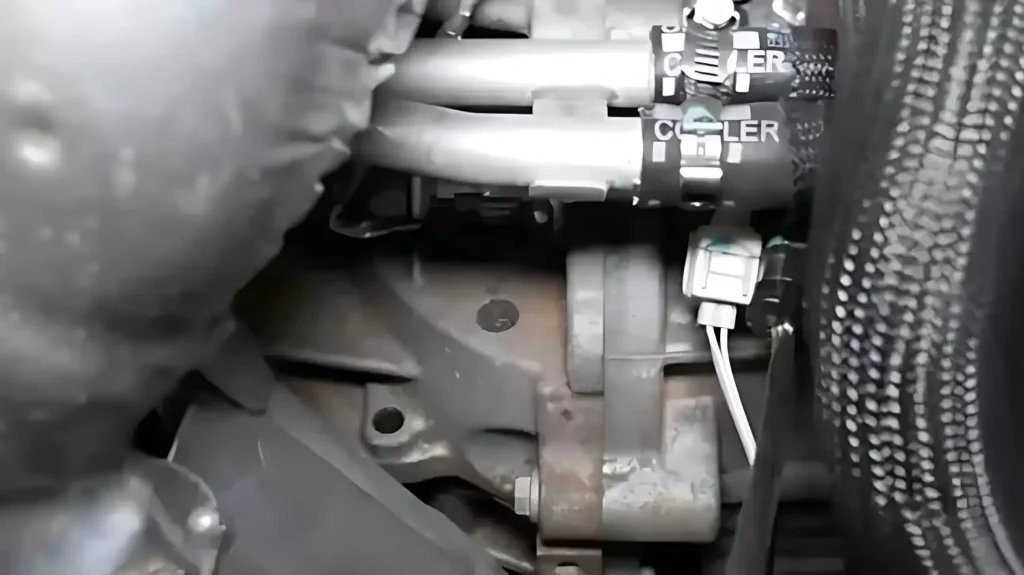

Step 2: Locate the crankshaft position sensor

The crankshaft position sensor is typically located on the bottom of the engine block, near the crankshaft pulley.

The exact location may vary depending on the make and model of your vehicle, so consult your owner’s manual or a service manual for specific instructions.

Step 3: Disconnect the battery

To perform the relearn, you need to disconnect the battery for a few minutes.

This will reset the computer’s memory and allow it to relearn the position of the crankshaft sensor.

Locate the negative battery cable and use a wrench to loosen the nut to disconnect the battery. Carefully remove the cable from the battery and set it aside.

Step 4: Reconnect the battery

After a few minutes, reconnect the battery by carefully attaching the negative battery cable to the battery and tightening the nut with a wrench.

Be careful not to over-tighten the nut, as this can damage the battery terminal.

Step 5: Start your vehicle and let it idle

By starting your vehicle, let it idle for a few minutes. The computer will relearn the position of the crankshaft sensor.

You may notice that your vehicle’s idle speed is higher or lower than usual during this time, but this is normal.

Allow your vehicle to idle for at least 10 minutes to ensure that the relearning process is complete.

Step 6: Test drive your vehicle

Once the relearning process is complete, test drive your vehicle to ensure that everything is working correctly.

If you still experience issues with the crankshaft position sensor after performing the relearn, you may need to replace the sensor or seek further assistance from a qualified mechanic.

Signs of a Faulty Crankshaft Position Sensor

If the crankshaft position sensor is faulty, your vehicle may experience a variety of issues, like,

Hard starting or no start:

A faulty crankshaft position sensor can cause your vehicle to have difficulty starting or not start at all.

This is because the ECM relies on the sensor’s data to determine when to send the spark and fuel to the engine.

If the sensor is not functioning correctly, the ECM may not know when to send these signals, leading to starting issues.

Stalling:

A faulty crankshaft position sensor can cause your vehicle to stall while driving or idling.

This is because the ECM relies on the sensor’s data to control ignition timing and fuel injection.

If the sensor is not providing accurate information, the ECM may not be able to control these functions correctly, leading to stalling.

Poor engine performance:

A faulty crankshaft position sensor can cause your vehicle’s engine to run poorly.

This can include rough idling, hesitation or stumbling during acceleration, and a decrease in power and fuel efficiency.

These issues can be caused by inaccurate information from the sensor, leading to incorrect engine timing and fuel delivery.

Check engine light:

A faulty crankshaft position sensor can trigger the check engine light to come on.

This is because the ECM can detect when the sensor is not providing accurate data and will set a diagnostic trouble code (DTC) in the system.

You can use a diagnostic scan tool to read the code and determine the cause of the issue.

Common Mistakes to Avoid During GM Crankshaft Position Sensor Relearn

There are some common mistakes that people make during this process that can lead to issues.

Skipping the sensor replacement:

The crankshaft position sensor may fail, and the vehicle may require a replacement.

Some people skip the replacement step, assuming that relearning the sensor will fix the issue.

It’s crucial to replace the faulty sensor before performing the relearning process.

Ignoring the manufacturer’s instructions:

GM has specific instructions on how to perform the crankshaft position sensor relearn process.

Read and follow the instructions carefully to avoid making mistakes. Ignoring the instructions can lead to issues, such as the vehicle not starting, stalling, or running poorly.

Not using the correct tools:

The GM crankshaft position sensor relearn process requires specific tools.

Using the wrong tools can lead to incorrect results, causing issues such as the vehicle running poorly or stalling.

Make sure to use the correct tools recommended by GM for the relearning process.

Performing the relearn process incorrectly:

The relearning process involves several steps that need to be followed correctly.

For instance, some people may not complete the process in the recommended time frame, leading to incorrect results.

It’s essential to follow the instructions and complete the process within the recommended time frame.

Not testing the vehicle after the relearning process:

Once you have completed the GM crankshaft position sensor relearn process, it’s crucial to test the vehicle to ensure it’s running correctly.

Not testing the vehicle can lead to issues, such as the check engine light coming on or the vehicle stalling while driving.

Benefits of GM Crankshaft Position Sensor Relearn

The relearn process is designed to recalibrate the sensor, which monitors the position and speed of the crankshaft. But it has some benefits like,

Improved engine performance:

The crankshaft position sensor is a critical component of your vehicle’s engine management system.

If the sensor is not calibrated correctly, it can lead to issues such as poor engine performance, decreased power and fuel efficiency, and rough idling.

Performing a relearn can help ensure that the sensor is providing accurate data, which can lead to improved engine performance.

Increased fuel efficiency:

A faulty crankshaft position sensor can cause your vehicle to burn more fuel than necessary, leading to decreased fuel efficiency.

By performing a relearn, you can help ensure that the sensor is providing accurate data to the engine management system, which can lead to increased fuel efficiency.

Reduced emissions:

A relearn can help ensure that your vehicle is running efficiently, which can lead to reduced emissions.

A faulty crankshaft position sensor can cause the engine to run poorly, leading to increased emissions.

By performing a relearn, you can help reduce your vehicle’s impact on the environment.

Prevent future issues:

If the crankshaft position sensor is not calibrated correctly, it can lead to more severe issues, such as stalling or engine failure.

You can help prevent these issues from occurring and ensure that your vehicle is running smoothly.

Longer engine life:

By ensuring that your vehicle’s engine is running efficiently, you can help extend its lifespan.

A faulty crankshaft position sensor can cause unnecessary wear and tear on the engine, leading to a shorter lifespan.

You can help ensure that the engine is running correctly, which can lead to a longer lifespan.

When Should You Perform GM Crankshaft Position Sensor Relearn?

Here are some situations when you should perform GM crankshaft position sensor relearn:

After replacing the sensor:

If you’ve replaced the crankshaft position sensor, you should perform a relearn process.

The new sensor will need to be calibrated correctly to ensure that it’s providing accurate data to the engine management system.

After making engine repairs:

If you’ve made significant engine repairs, such as replacing the timing belt or camshaft, you should perform a relearning process.

These repairs can affect the position and speed of the crankshaft, requiring a recalibration of the crankshaft position sensor.

After clearing the check engine light:

If the check engine light comes on and you’ve cleared it, you should perform a relearning process.

Clearing the check engine light can erase data that the engine management system needs to operate correctly. A relearning process can help restore this data.

After a battery replacement:

If you’ve replaced the battery, you should perform a relearning process.

The replacement of the battery can cause the engine management system to lose data, which can affect the position and speed of the crankshaft.

After experiencing engine issues:

If you’re experiencing engine issues such as poor performance, rough idling, or decreased fuel efficiency, you should perform a relearning process.

A faulty crankshaft position sensor can cause these issues, and recalibrating the sensor can help improve engine performance.

FAQs

Why Do I Need To Perform A GM Crankshaft Position Sensor Relearn?

You need to perform a GM crankshaft position sensor relearn for several reasons, including after replacing the sensor, making significant engine repairs, clearing the check engine light, replacing the battery, or experiencing engine issues.

How Often Should I Perform A GM Crankshaft Position Sensor Relearn?

The frequency of performing a GM crankshaft position sensor relearn depends on the specific situation.

If you’ve replaced the sensor or made significant engine repairs, you should perform a relearning process.

If you’re experiencing engine issues or have cleared the check engine light, you should also perform a relearn process.

Consult your vehicle’s owner’s manual or seek advice from a qualified mechanic to determine the appropriate frequency.

Can I Perform A GM Crankshaft Position Sensor Relearn Myself?

Yes, you can perform a GM crankshaft position sensor relearn yourself if you have the necessary tools and knowledge.

If you’re not confident in your ability to perform the relearning process, it’s essential to seek advice from a qualified mechanic.

What Happens If I Don’t Perform A GM Crankshaft Position Sensor Relearn?

If you don’t perform a GM crankshaft position sensor relearn when necessary, you may experience issues such as poor engine performance, decreased fuel efficiency, rough idling, stalling, or engine failure.

A faulty crankshaft position sensor can cause significant damage to your vehicle’s engine, so it’s essential to perform a relearning process when necessary.

Conclusion

Performing a GM crankshaft position sensor relearn is a crucial process that can help ensure your vehicle’s engine runs smoothly and efficiently.

By avoiding common mistakes and following the proper steps, you can reap the benefits of improved engine performance, increased fuel efficiency, and reduced emissions.

Regular maintenance and care of your vehicle’s crankshaft position sensor can help prevent costly repairs and ensure your vehicle runs at its best.