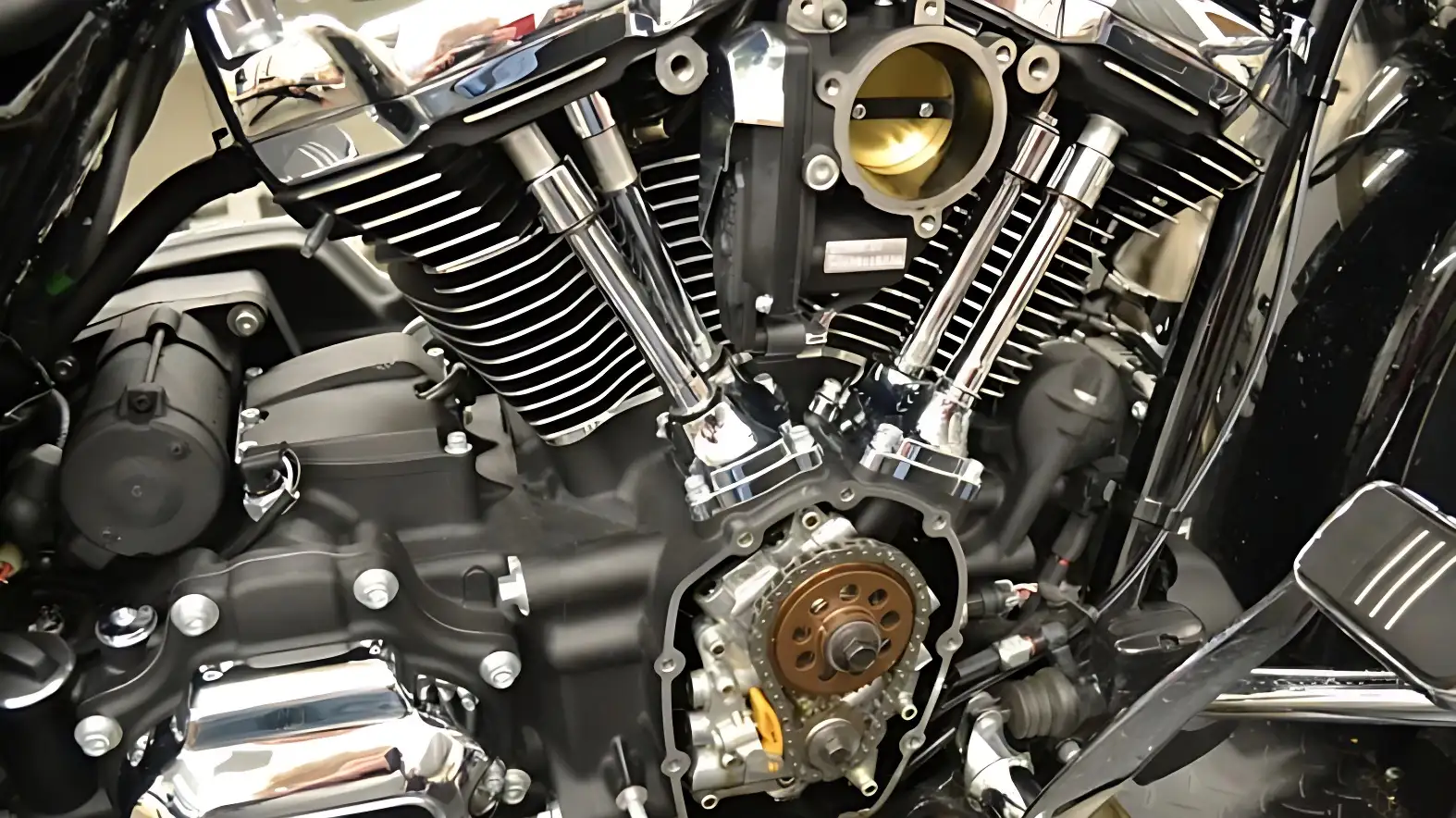

The Milwaukee-Eight 107 engine is a popular choice for Harley-Davidson motorcycles, known for its powerful performance and smooth ride.

Like any complex machinery, it is not immune to problems. In this blog, we will explore the top 10 issues that riders may encounter with the Milwaukee-Eight 107 engine, as well as tips for troubleshooting and solving these problems.

If you are a newcomer to the Harley-Davidson community, this guide will help you understand the potential issues with this engine and how to address them.

Milwaukee eight 107 problems

Milwaukee Eight 107 engines have been known to experience various problems, and it is essential to be aware of these issues.

Below are some of the most common problems associated with this engine and their possible solutions.

Engine noise:

Some riders have reported excessive engine noise, especially when the bike is idling.

This could be due to worn-out lifters or rocker’s arms. The solution is to replace the affected parts with new ones.

Overheating:

Milwaukee Eight 107 engines can overheat, especially during long rides. This could be due to a malfunctioning cooling system or low coolant levels.

It is advisable to check the coolant levels before every ride and ensure that the cooling system is functioning correctly.

Low oil pressure:

Some riders have reported low oil pressure, which could be due to a faulty oil pump or clogged oil passages.

It is recommended to check the oil pressure regularly and replace the oil pump if necessary.

Misfires:

Misfires occur when the fuel in the combustion chamber fails to ignite correctly. This could be due to a faulty ignition system or clogged fuel injectors.

It is advisable to have the ignition system and fuel injectors checked regularly and replaced if necessary.

Clutch problems:

The Milwaukee Eight 107 engine can experience clutch problems, such as slipping or sticking.

This could be due to worn-out clutch plates or a malfunctioning clutch cable. The solution is to replace the affected parts with new ones.

Engine stalling:

The engine can stall, especially when idling or decelerating. This could be due to a faulty idle air control valve or clogged fuel injectors.

It is advisable to have the idle air control valve and fuel injectors checked regularly and replaced if necessary.

Vibration:

Some riders have reported excessive vibration, especially at high speeds. This could be due to worn-out engine mounts or a misaligned drive belt.

It is advisable to have the engine mounts and drive belt checked regularly and replaced if necessary.

How to Diagnose Engine Overheating

Engine overheating can be a serious problem for your vehicle, and diagnose and fix it as soon as possible.

Here are some steps you can take to diagnose engine overheating:

Check the coolant level:

The first thing to check is the coolant level in your vehicle.

Low coolant levels can cause engine overheating, and it is important to ensure that the coolant level is at the appropriate level.

Check the radiator:

The radiator is responsible for dissipating heat from the engine, and a malfunctioning radiator can cause engine overheating.

Check the radiator for any signs of damage or leaks, and ensure that the fins are clean and free of debris.

Check the water pump:

The water pump circulates coolant throughout the engine and is critical for maintaining engine temperature.

A malfunctioning water pump can cause engine overheating, and it is important to check the water pump for any signs of damage or leaks.

Check the thermostat:

The thermostat regulates the engine temperature by opening and closing based on the engine temperature.

A malfunctioning thermostat can cause engine overheating, and it is important to check the thermostat for any signs of damage or wear.

Check the cooling fan:

The cooling fan is responsible for drawing air through the radiator to dissipate heat.

A malfunctioning cooling fan can cause engine overheating, and it is important to ensure that the fan is working properly.

Check the belts and hoses:

Belts and hoses are critical components of the cooling system and can cause engine overheating if they are damaged or worn.

Check the belts and hoses for any signs of damage or wear and replace them if necessary.

Tips for Improving Fuel Economy

Improving fuel economy can save you money and reduce your environmental impact. Here are some tips for improving your fuel economy:

Drive smoothly:

Aggressive driving, such as rapid acceleration and hard braking, can decrease fuel economy by up to 33%.

Drive smoothly and avoid unnecessary acceleration and braking to improve fuel economy.

Maintain proper tire pressure:

Underinflated tires can decrease fuel economy by up to 3%.

Check your tire pressure regularly and maintain the proper pressure recommended by your vehicle manufacturer.

Use the correct oil:

Using the manufacturer-recommended oil can improve fuel economy by up to 2%.

Check your owner’s manual to ensure that you are using the recommended oil for your vehicle.

Remove excess weight:

Extra weight in your vehicle can decrease fuel economy. Remove any unnecessary items from your vehicle, such as roof racks or heavy cargo, to improve fuel economy.

Use cruise control:

Using cruise control can help maintain a consistent speed and improve fuel economy, especially on long highway drives.

Avoid idling:

Idling can waste fuel and decrease fuel economy. Turn off your engine when you are parked or waiting for someone to improve fuel economy.

Plan your route:

Efficient route planning can help you avoid traffic and other delays, which can decrease fuel economy.

Use GPS or other navigation tools to find the most direct and efficient route to your destination.

Preventing Oil Leaks

Proper Maintenance:

Regular maintenance of equipment and machinery is crucial to prevent oil leaks.

Check all gaskets, seals, and hoses for signs of wear or damage. Replace any faulty components immediately to avoid potential leaks.

Use High-Quality Oil:

Using high-quality oil reduces the likelihood of leaks.

Choose a product that is specifically designed for your equipment and follows the manufacturer’s recommendations.

Avoid using old or contaminated oil, which can cause leaks and damage.

Install Oil Containment Systems:

Installing oil containment systems is an effective way to prevent leaks from causing environmental damage.

Install secondary containment systems, such as drip pans or leak detection devices, to capture oil spills before they spread.

Train Personnel:

Proper training of personnel is essential to prevent oil leaks. Train employees to identify and respond to oil leaks and spills effectively.

Develop and implement procedures for handling and disposing of oil and contaminated materials.

Monitor Oil Levels:

Regularly monitoring oil levels is critical to prevent leaks.

Ensure oil levels are not too low or too high, as both can cause leaks. Check oil levels regularly and top up as necessary.

Inspect Equipment:

Regular inspection of equipment can help identify potential issues before they lead to leaks.

Conduct visual inspections and use diagnostic tools to detect potential issues such as corrosion or fatigue.

Store Oil Properly:

Proper storage of oil is essential to prevent leaks. Store oil in a dedicated, well-ventilated area away from potential sources of ignition.

Use appropriate containers and labeling to prevent confusion and mishandling.

Respond Quickly:

If a leak does occur, it is essential to respond quickly. Develop and implement an emergency response plan to ensure a rapid and effective response.

Ensure all personnel is trained and equipped to respond to oil leaks and spills.

Solving Engine Knocking Problems

Engine knocking is a common problem that occurs in internal combustion engines.

It is caused by incorrect combustion, which results in a knocking or pinging sound. Here are some steps you can take to solve engine knocking problems:

Use High-Quality Fuel:

Using low-quality fuel or fuel with a low octane rating can cause engine knocking. Use high-quality fuel with the recommended octane rating to prevent knocking.

Check and Adjust Ignition Timing:

Incorrect ignition timing can cause engine knocking. Check the ignition timing and adjust it as necessary. You can find the recommended timing in the vehicle’s manual.

Replace Spark Plugs:

Worn or dirty spark plugs can cause engine knocking. Replace the spark plugs if they are worn or dirty.

Clean Carbon Buildup:

Carbon buildup on the pistons, valves, and cylinder walls can cause engine knocking. Clean the buildup using a carbon cleaning solution or have a professional clean it for you.

Use Oil Additives:

Some oil additives can reduce engine knocking. Look for additives that contain detergents or dispersants to keep the engine clean and prevent knocking.

Check Engine Sensors:

Faulty engine sensors, such as the knock sensor, can cause engine knocking. Check the sensors and replace them if necessary.

Check Engine Bearings:

Worn engine bearings can cause engine knocking. Check the bearings and replace them if necessary.

Avoid Overloading:

Overloading the engine can cause knocking. Avoid excessive loads and try to drive at a steady speed.

Get Professional Help:

If you have tried these steps and the engine knocking persists, it may be time to seek professional help. A mechanic can diagnose the problem and suggest the best course of action.

How to Fix Transmission Issues

Transmission issues that can be frustrating and expensive to repair. Here are some steps you can take to fix transmission problems:

Check Transmission Fluid:

Low transmission fluid levels can cause transmission issues. Check the transmission fluid level and add more fluid if necessary. Make sure to use the correct type of fluid for your vehicle.

Replace Transmission Filter:

A clogged transmission filter can cause transmission issues. Replace the filter and clean the transmission pan before installing the new filter.

Repair Leaks:

Leaking transmission fluid can cause transmission problems. Locate and repair any leaks in the transmission system.

Check Transmission Control Module:

The transmission control module (TCM) controls the transmission’s shifting. A faulty TCM can cause transmission issues. Have the TCM checked and replace it if necessary.

Replace Transmission Solenoids:

Transmission solenoids control the flow of fluid in the transmission. A faulty solenoid can cause transmission issues. Replace the solenoids if necessary.

Check Transmission Mounts:

Broken or worn transmission mounts can cause transmission issues. Check the mounts and replace them if necessary.

Adjust Shifter Linkage:

A misaligned or worn shifter linkage can cause transmission problems. Adjust or replace the shifter linkage as necessary.

Have Transmission Rebuilt:

If the above steps do not solve the transmission issues, it may be necessary to have the transmission rebuilt. A professional transmission mechanic can rebuild the transmission and replace any worn or damaged parts.

Replace Entire Transmission:

It may be necessary to replace the entire transmission. This is a more expensive option may be necessary if the transmission is severely damaged or cannot be repaired.

Troubleshooting Starter Problems

Starter problems can prevent your vehicle from starting, leaving you stranded. Here are some steps you can take to troubleshoot starter problems:

Check Battery:

A weak or dead battery can cause starter problems. Check the battery voltage with a multimeter and make sure it is fully charged. If the battery is weak or dead, replace it.

Check Battery Connections:

Loose or corroded battery connections can cause starter problems. Check the battery terminals and cables for corrosion and tightness. Clean or replace the terminals and cables as necessary.

Check Starter Connections:

Loose or corroded starter connections can cause starter problems. Check the starter terminals and cables for corrosion and tightness. Clean or replace the terminals and cables as necessary.

Test Starter Motor:

A faulty starter motor can cause starter problems. Use a multimeter to test the starter motor’s voltage and amperage draw. If the motor fails the test, replace it.

Check Starter Relay:

The starter relay controls the flow of electricity to the starter motor. A faulty relay can cause starter problems. Use a multimeter to test the relay and replace it if necessary.

Check Ignition Switch:

The ignition switch sends a signal to the starter motor to start the engine. A faulty switch can cause starter problems. Test the switch and replace it if necessary.

Check Neutral Safety Switch:

The neutral safety switch prevents the engine from starting while in gear. A faulty switch can cause starter problems. Test the switch and replace it if necessary.

Check Starter Solenoid:

The starter solenoid engages the starter motor. A faulty solenoid can cause starter problems. Test the solenoid and replace it if necessary.

Have Professional Diagnosis:

If you have tried these steps and the starter problems persist, it may be time to seek professional help.

A mechanic can diagnose the problem and suggest the best course of action.

Common Electrical Malfunctions and Solutions

Electrical malfunctions can be frustrating and dangerous. Here are some common electrical malfunctions and their solutions:

Circuit Overload:

Circuit overload occurs when too many devices are connected to a single circuit, causing the circuit to trip.

The solution is to redistribute the devices on different circuits or install additional circuits.

Short Circuit:

A short circuit occurs when a hot wire comes into contact with a neutral wire, causing a spark and possibly a fire.

Carefully identify and repair the damaged wires and replace any damaged devices.

Faulty Switches and Outlets:

Faulty switches and outlets can cause electrical malfunctions. Just replace the damaged switches or outlets with new ones.

Flickering Lights:

Flickering lights can be caused by loose connections or a faulty fixture. Tighten the connections or replace the fixture.

Electrical Surges:

Electrical surges can damage electrical devices. The solution is to install surge protectors to protect devices from voltage spikes.

Tripped Breakers:

Tripped breakers occur when a circuit is overloaded or shorted. Reset the breaker by turning it off and then back on again to solve the issue.

GFCI Outlets Not Working:

GFCI outlets protect against electrical shock. If they are not working, simply reset the outlet by pressing the “reset” button.

Damaged Wiring:

Damaged wiring can cause electrical malfunctions and be a fire hazard. The solution is to identify and repair the damaged wiring or replace it if necessary.

Circuit Breakers Constantly Tripping:

If circuit breakers constantly trip, it may indicate a larger electrical problem. The solution is to have a professional electrician inspect the electrical system to identify and repair any issues.

FAQs

How Can Oil Leaks In The Milwaukee Eight 107 Engine Be Fixed?

Oil leaks in the Milwaukee Eight 107 engine can be fixed by identifying the source of the leak and replacing any faulty gaskets, seals, or connections.

Why Does The Milwaukee Eight 107 Engine Generate Excessive Heat?

Excessive engine heat in the Milwaukee Eight 107 engine can be caused by a variety of factors, including poor airflow, a malfunctioning thermostat, or an issue with the cooling system.

How Can Excessive Engine Heat In The Milwaukee Eight 107 Engine Be Addressed?

Excessive engine heat in the Milwaukee Eight 107 engine can be addressed by ensuring proper airflow, replacing a malfunctioning thermostat, or having the cooling system inspected and repaired by a professional.

What Are The Cam Chain Tensioner Issues In The Milwaukee Eight 107 Engine?

Cam chain tensioner issues in the Milwaukee Eight 107 engine can cause noise, vibration, and even engine damage.

The cam chain tensioner is responsible for maintaining proper tension on the engine’s timing chain.

How Can Cam Chain Tensioner Issues In The Milwaukee Eight 107 Engine Be Fixed?

Cam chain tensioner issues in the Milwaukee Eight 107 engine can be fixed by replacing the tensioner with a redesigned version or upgrading to a hydraulic tensioner kit.

Is It Safe To Ride A Motorcycle With These Issues?

It is not recommended to ride a motorcycle with these issues, as they can cause further damage to the engine or create unsafe riding conditions.

It’s best to have these issues addressed by a professional before riding the motorcycle again.

Conclusion

The Milwaukee Eight 107 engine has had some reported problems, including oil leaks, excessive heat, and ticking noises.

While these issues may be concerning, it’s important to note that they are not present in all engines and may be addressed through proper maintenance and repairs.

With regular upkeep and attention to these potential problems, the Milwaukee Eight 107 can still be a reliable and high-performing engine option for Harley-Davidson motorcycles.