Are you wondering if valve springs can add horsepower to your engine?

Many car enthusiasts believe that upgraded valve springs can help increase engine performance, but is it really true?

In this blog post, we’ll take a closer look at the role of valve springs in an engine, explore the potential benefits of upgrading them, and answer the question: do valve springs really add horsepower?

Do Valve Springs Add Horsepower?

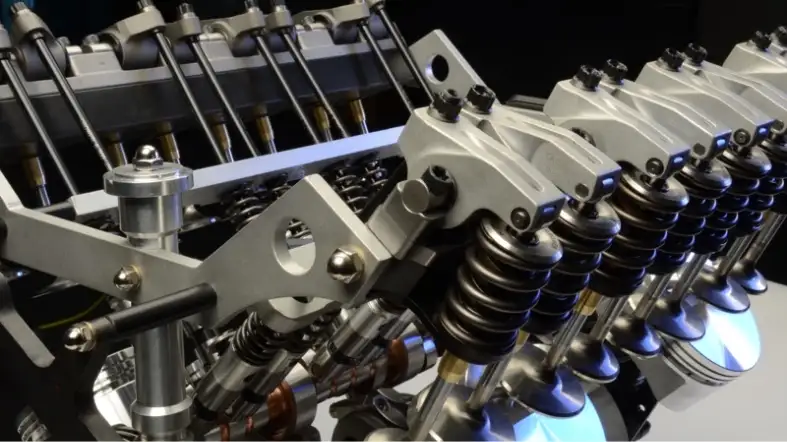

Valve springs themselves do not directly add horsepower to an engine. However, they do play a crucial role in maintaining proper valve control and preventing valve float at high rpm levels.

Valve float occurs when the valve spring can no longer keep the valve closed and the valve “floats” open, leading to a loss of power and potential engine damage.

Upgrading to higher quality or high-performance valve springs can help prevent valve float, allowing for higher rpm levels and potentially more power.

Additionally, properly matched valve springs can be important when upgrading other engine components such as camshafts or cylinder heads, to ensure optimal performance and reliability.

The potential impact of upgraded valve springs on horsepower

By using springs with a higher spring rate and better materials, you can prevent valve float and maintain consistent valve control, resulting in improved engine performance.

Valve Float

Valve float occurs when the valve spring is unable to close the valve completely due to the pressure of the camshaft.

This can cause a loss of power and can even lead to engine damage.

Upgraded valve springs with higher spring rates can prevent valve float and ensure consistent valve control, resulting in improved horsepower.

Consistent Valve Control

Upgraded valve springs with better materials, such as chrome silicon or titanium, can provide consistent valve control even under extreme conditions.

This consistency can help maintain optimal valve timing and prevent valve float, resulting in improved horsepower.

Increased Lift

By using upgraded valve springs with higher spring rates, you can achieve higher lift on your valves.

This increased lift can allow for more air and fuel to enter the combustion chamber, resulting in improved horsepower and torque.

Choosing the Right Valve Springs

To achieve the maximum horsepower gains, it’s important to choose the right valve springs for your specific engine and application.

Factors such as engine speed, valve lift, and spring design should all be taken into consideration when selecting upgraded valve springs.

Factors that affect valve spring performance

Here are some factors that can affect valve spring performance:

Temperature

Valve springs are exposed to high temperatures in the engine bay, and this heat can weaken them over time.

If your engine is running hot, your valve springs might wear out quicker and cause reduced performance.

Upgraded valve springs can withstand higher temperatures and are better suited for high-performance engines.

Engine Speed

As your engine’s speed increases, the pressure on your valve springs also increases.

This can cause your springs to break or wear out more quickly, which can lead to serious engine problems.

Choosing high-quality valve springs with the correct spring rate can help prevent this issue.

Valve Lift

The amount of lift your valves achieve can also affect your valve spring’s performance.

Higher lift puts more pressure on the springs, which can cause them to wear out more quickly.

Upgraded valve springs with higher spring rates can help prevent this type of failure and ensure optimal engine performance.

Spring Design

Different types of valve springs have different characteristics that can affect their performance.

The number of coils, the thickness of the wire, and the shape of the spring can all impact how well it functions under different conditions.

It’s important to choose valve springs that are specifically designed for your engine and application.

Wear and Tear

Like any other engine component, valve springs can wear out over time due to repeated stress and fatigue.

Regular maintenance and inspection can help you catch any issues before they become serious problems.

Signs of worn-out valve springs can include poor performance, rough idling, and unusual engine noises.

Replacing worn-out springs with high-quality, properly rated valve springs can help prevent these types of issues.

How do I choose the right valve springs for my engine?

Choosing the right valve springs for your engine can be a complex process that involves several factors. Here are some key considerations to keep in mind:

Engine speed:

The valve springs you choose should be able to handle the maximum RPM your engine is capable of.

If you’re building a high-performance engine that will see high RPMs, you’ll need valve springs with a higher spring rate and/or better damping characteristics.

Valve lift:

The valve springs must be able to control the valve motion throughout the entire lift range.

If you’re planning on upgrading to a higher lift camshaft, you may need valve springs with a higher spring rate to prevent valve float.

Spring design:

There are several different types of valve springs available, including single, dual, and triple springs.

Single springs are the simplest and most affordable option, but may not provide enough spring pressure for high-performance engines.

Dual and triple springs offer more spring pressure but are more complex and expensive.

Material:

Valve springs are typically made from steel or titanium. Titanium springs are lighter and can handle higher RPMs, but are more expensive than steel springs.

Brand reputation:

It’s important to choose valve springs from a reputable brand that has a proven track record of quality and reliability.

Application:

The valve springs you choose should be specifically designed for your engine and application.

This means considering factors such as vehicle weight, intended use, and other modifications you’ve made to your engine.

Other considerations when upgrading valve springs

When upgrading valve springs, there are several other considerations to keep in mind to ensure optimal performance and longevity.

Retainers

Upgraded valve springs often require upgraded retainers to handle the higher spring rates.

It’s important to choose retainers that are specifically designed for your valve springs and engine.

Keepers

Upgraded valve springs may require new keepers to hold the valves in place. It’s important to choose keepers that are compatible with your new valve springs.

Lifters

The lifters in your engine may also need to be upgraded to handle the higher spring rates.

It’s important to choose lifters that are specifically designed for your engine and valve springs.

Rocker Arms

Upgraded valve springs can put additional stress on your rocker arms.

It’s important to choose high-quality, properly rated rocker arms to ensure they can handle the increased stress.

Pushrods

Upgraded valve springs can also put additional stress on your pushrods.

It’s important to choose pushrods that are properly sized and rated for your engine and valve springs.

Tuning

When upgrading valve springs, it’s important to properly tune your engine to take advantage of the improved performance.

This may involve adjusting fuel and ignition timing, among other things.

Installation

Proper installation is critical to ensure your upgraded valve springs function properly and provide optimal performance.

It’s important to follow manufacturer guidelines and use proper tools and techniques when installing your new valve springs.

Maintenance

Upgraded valve springs, like any other engine component, require regular maintenance to ensure they continue to function properly.

This may involve regular inspections, cleaning, and occasional replacement to prevent issues and maintain optimal performance.

FAQs

Can Upgraded Valve Springs Improve Horsepower?

Yes, upgraded valve springs can improve horsepower by preventing valve float and maintaining consistent valve control, which allows for more air and fuel to enter the combustion chamber.

How Much Of A Horsepower Increase Can I Expect From Upgraded Valve Springs?

The amount of horsepower increase you can expect will depend on several factors, including the specific valve springs you choose, your engine’s current setup, and how well your engine is tuned.

However, many people report gains of 5-20 horsepower with upgraded valve springs.

Do I Need To Upgrade My Valve Springs If I’m Not Building A High-Performance Engine?

If you’re not building a high-performance engine, you may not need to upgrade your valve springs.

However, if you’re making other upgrades to your engine or driving in demanding conditions, upgraded valve springs can help ensure optimal performance and prevent engine damage.

Can I Install Upgraded Valve Springs Myself?

While it’s possible to install upgraded valve springs yourself, it can be a challenging process that requires specialized tools and knowledge.

If you’re not experienced with engine work, it’s recommended that you have a professional mechanic handle the installation.

Are There Any Downsides To Upgrading Valve Springs?

Upgrading valve springs can put additional stress on other engine components, such as lifters and rocker’s arms.

It’s important to choose high-quality components and ensure they’re properly rated for your engine to prevent issues and ensure longevity.

Do I Need To Tune My Engine After Upgrading Valve Springs?

Yes, it’s important to tune your engine after upgrading valve springs to ensure optimal performance and prevent issues such as detonation.

Tuning may involve adjusting fuel and ignition timing, among other things.

Conclusion

Upgrading valve springs can have a significant impact on the performance of your engine.

By selecting the right valve springs for your engine, you can increase horsepower, reduce valve float, and improve overall engine efficiency.

All of the factors that can impact valve spring performance, including engine speed, valve lift, spring design, material, brand reputation, and application.

With careful consideration and proper installation, upgrading your valve springs can be a cost-effective way to boost the performance of your engine.