If you own a Chevy with a 6.0-liter engine, you may have experienced issues with the crankshaft position sensor.

This crucial component can cause a range of problems, from engine stalling to misfires.

Thankfully, the solution is often a simple one – a crank sensor relearn procedure.

In this blog post, we’ll explain what the crank sensor does, why it needs relearning, and how you can perform the procedure yourself.

Chevy 6.0 Crank Sensor Relearn

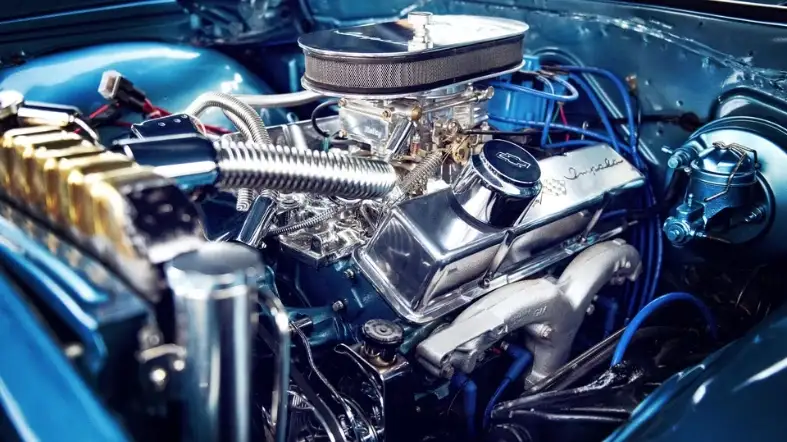

The Chevy 6.0 engine is equipped with a crankshaft position sensor that helps the engine control module (ECM) determine the engine speed and position for proper engine operation. If the sensor or its wiring is replaced, a relearn procedure might be required to reset the parameters of the ECM.

Why Does the Chevy 6.0 Need a Crank Sensor Relearn?

Over time, the calibration of the crank sensor can become inaccurate due to wear and tear, engine modifications, or battery replacement.

This can lead to a loss of engine performance, reduced fuel efficiency, and even engine failure.

Therefore, it is necessary to relearn the crank sensor periodically to ensure that it is functioning correctly.

Tools Needed for a Crank Sensor Relearn

To perform this task, you’ll need a few essential tools.

OBD-II Scanner

The first tool you’ll need is an OBD-II scanner. This device allows you to communicate with the ECM and retrieve diagnostic trouble codes (DTCs).

It’s important to note that not all OBD-II scanners can perform a crank sensor relearn. You’ll need a scanner that’s capable of performing this function.

Battery Charger

A low battery charge can cause the ECM to fail to complete a crank sensor relearn. To avoid this issue, it’s best to use a battery charger during the relearning process.

A fully charged battery ensures that the ECM has enough power to complete the relearn.

Ratchet and Socket Set

You’ll also need a ratchet and socket set to remove any necessary parts to access the crankshaft position sensor.

This may include the engine cover, the air intake system, or other components.

Service Manual

It’s important to have a service manual specific to your vehicle’s make and model.

The manual provides detailed instructions for performing a crank sensor relearn, as well as any necessary precautions or warnings.

Assistant

A second person can be helpful during a crank sensor relearns, particularly during the relearn procedure itself.

The assistant can help monitor the scanner and make any necessary adjustments to the throttle or other components.

How to Perform a Chevy 6.0 Crank Sensor Relearn

This process involves resetting the sensor’s position and ensuring accurate communication with the engine control module (ECM).

Here’s how to perform a Chevy 6.0 crank sensor relearn.

Step 1: Locate the OBD-II port

The first step is to locate the OBD-II port, which is typically located under the dashboard on the driver’s side of the vehicle.

Once located, connect the OBD-II scanner to the port.

Step 2: Check for codes

Before starting the relearn process, it’s important to check for any diagnostic trouble codes (DTCs).

These codes will give you an idea of what might be causing the issue and can help you troubleshoot further.

If any codes are present, address them before proceeding with the relearn.

Step 3: Turn the ignition to the “On” position

Put the key in the “On” position but don’t start the engine.This will power the ECM and allow it to communicate with the OBD-II scanner.

Step 4: Select the crank sensor relearn function

Using the OBD-II scanner, select the crank sensor relearn function from the menu. This will initiate the relearn process and reset the sensor’s position.

Step 5: Follow the on-screen instructions

Follow the on-screen instructions provided by the scanner to complete the relearn process.

This may involve starting and stopping the engine at specific intervals or holding the accelerator pedal down for a certain period of time.

Step 6: Clear any DTCs

Once the relearn process is complete, clear any DTCs that may have been triggered during the process.

This will ensure accurate communication between the sensor and ECM moving forward.

Common Mistakes to Avoid During the Relearn Process

Here we’ll explore some of these mistakes and offer tips to help you avoid them.

Skipping the Basics

One of the most common mistakes people make when relearning a skill or subject is to skip the basics.

It’s tempting to dive right into the more advanced material, especially if you have some prior knowledge of the subject.

However, skipping the basics can be detrimental to your understanding of the material.

You may miss out on important foundational concepts that will be crucial to your success as you move forward.

To avoid this mistake, start by reviewing the basics. Go back to the beginning of your textbook or course materials and work through the foundational concepts.

Even if you feel like you already understand the material, taking the time to review the basics can help solidify your understanding and ensure you don’t miss any important concepts.

Focusing Too Much on Memorization

Another common mistake people make when relearning a subject is to focus too much on memorization.

While memorization is certainly an important part of learning, it’s not the only aspect.

If you focus too much on memorization, you may miss out on the deeper understanding that comes from truly grasping a concept.

To avoid this mistake, focus on understanding the material rather than just memorizing it.

Ask yourself why a particular concept works the way it does and how it fits into the bigger picture of the subject.

This deeper understanding will not only help you remember the material better but also allow you to apply it in new and different ways.

Not Practicing Enough

Practice is essential when relearning a skill, but it’s a common mistake to not practice enough.

It’s easy to get caught up in reading and reviewing material, but if you don’t take the time to practice applying what you’ve learned, you may struggle to truly master the material.

To avoid this mistake, make sure to practice regularly. If you’re relearning a physical skill, such as playing an instrument or sport, set aside time each day to practice.

If you’re relearning a mental skill, such as coding or math, work through practice problems regularly to reinforce your understanding.

Being Too Hard on Yourself

Finally, one of the most common mistakes people make when relearning a skill or subject is being too hard on themselves.

It’s easy to get frustrated when you don’t remember something you feel like you should know, but beating yourself up over it will only make it harder to learn.

To avoid this mistake, be kind to yourself. Remember that relearning is a process, and it’s okay to make mistakes along the way.

Celebrate your successes, no matter how small, and use any setbacks as an opportunity to learn and grow.

Factors Affecting the Frequency of a Crank Sensor Relearn

Here are the factors affecting the frequency of a crank sensor relearn:

Vehicle Make and Model

The make and model of the vehicle is a significant factors in determining how frequently the crank sensor relearn process should be performed.

Different manufacturers have varying recommendations for when the relearn should be performed, with some suggesting that it is only necessary after major repairs, while others recommend a regular interval of every 50,000 miles.

Driving Conditions

The driving conditions under which the vehicle is operated can also impact the frequency of the crank sensor relearn process.

In general, if the vehicle is subjected to extreme temperatures or harsh driving conditions, such as heavy towing or high-speed driving, it may need more frequent relearning.

Sensor Quality

The quality of the crank sensor itself can also impact how often the relearn process needs to be performed.

Higher-quality sensors may be able to maintain their alignment for longer periods, while cheaper or lower-quality sensors may require more frequent recalibration.

Maintenance and Repair History

Finally, the maintenance and repair history of the vehicle can also play a role in how frequently the crank sensor relearn process is necessary.

If the vehicle has been subjected to significant repairs or has a history of sensor-related issues, it may need more frequent relearning to ensure optimal performance.

FAQs

How Often Should You Perform A Crank Sensor Relearn?

You should perform a crank sensor relearn when you replace the sensor or the engine control module.

Otherwise, it is unnecessary and not recommended. Consult your vehicle’s manual for specific instructions.

Can I Perform The Chevy 6.0 Crank Sensor Relearn Myself?

While it is technically possible to perform the Chevy 6.0 crank sensor relearn yourself, it is generally not recommended unless you have experience working with automotive diagnostics and are familiar with the specific procedure for your particular vehicle.

Improperly resetting the ECM can cause serious engine problems and may even lead to engine failure.

How Much Does It Cost To Have A Chevy 6.0 Crank Sensor Relearn Performed By A Mechanic?

The cost of a Chevy 6.0 crank sensor relearn can vary depending on the mechanic or dealership you choose, as well as your location.

Generally, the cost ranges from $100 to $200.

How Do I Know If I Need A Chevy 6.0 Crank Sensor Relearn?

If you have recently replaced the crankshaft position sensor, overhauled the engine, or are experiencing symptoms such as engine misfires, stalling, or difficulty starting, you may need a Chevy 6.0 crank sensor relearn.

A diagnostic tool can also be used to check for trouble codes related to the sensor.

What Happens If I Don’t Perform A Chevy 6.0 Crank Sensor Relearn?

If you don’t perform a Chevy 6.0 crank sensor relearn when it is necessary, the engine may not run properly and may even experience serious problems such as stalling or engine failure.

Additionally, ignoring the issue can cause damage to other engine components and result in more costly repairs down the line.

Conclusion

Performing a Chevy 6.0 crank sensor relearn is a crucial step to ensure your engine runs smoothly and efficiently.

The process involves resetting the sensor’s position in the engine’s timing sequence, which allows it to accurately measure the engine’s revolutions per minute (RPM).

By doing this, the engine control module (ECM) can adjust the fuel injection and ignition timing to optimize performance and fuel economy.

It’s important to follow the correct procedure when performing the relearn to avoid any issues down the line.

With a little know-how and the right tools, you can easily complete this task and enjoy the benefits of a properly functioning engine.