A blown head gasket can cause significant damage to a Kohler engine if not addressed promptly.

This critical component seals the engine’s combustion chambers and cooling system, and if it fails, it can cause overheating, loss of power, poor fuel efficiency, and other issues.

Understanding the symptoms of a blown head gasket on a Kohler engine can help you diagnose and repair the problem before it causes severe damage.

In this guide, we will explore the common symptoms, causes, and repair methods for a blown head gasket on a Kohler engine.

Symptoms of a blown head gasket on Kohler engine

Here are the issues for the symptoms of a blown head gasket on a Kohler engine:

Engine overheating:

A blown head gasket can cause the engine to overheat due to the combustion gases escaping into the cooling system and preventing proper circulation.

White smoke from the exhaust pipe:

The head gasket failure can allow coolant to enter the combustion chamber, causing white smoke to emit from the exhaust pipe.

Loss of power or acceleration:

A decrease in compression and a reduction in power or acceleration can occur due to a failure of the head gasket.

Poor fuel efficiency:

The head gasket failure can cause the engine to run inefficiently and waste fuel.

Milky oil or coolant in the engine:

A blown head gasket can cause oil and coolant to mix, resulting in a milky appearance in the engine oil or coolant reservoir.

Coolant leaking into the cylinders:

The head gasket failure can allow coolant to leak into the engine cylinders, resulting in hydro-locking and significant engine damage.

Presence of air bubbles in the radiator:

The head gasket failure can cause air bubbles to form in the radiator due to combustion gases escaping into the cooling system.

Loud hissing or bubbling sound from the radiator or engine:

The head gasket failure can cause a loud hissing or bubbling sound from the radiator or engine due to the escaping gases.

Low or fluctuating engine compression:

A blown head gasket can cause low or fluctuating engine compression, affecting engine performance and efficiency.

Causes Of Blown Head Gasket On Kohler Engine

Here are some common causes of a blown head gasket on a Kohler engine:

Overheating:

One of the most common causes of a blown head gasket is overheating due to a malfunctioning cooling system.

Overheating can cause the head gasket to warp or crack, leading to failure.

Age and wear and tear:

Over time, the head gasket can deteriorate due to normal wear and tear, leading to failure. This is especially true for older Kohler engines.

Poor maintenance:

Poor maintenance can also cause a blown head gasket.

Neglecting to change the engine oil, failing to replace worn-out parts, and not replacing the coolant can all contribute to head gasket failure.

Improper installation:

If the head gasket is not installed correctly during engine assembly or repair, it can fail prematurely.

Incorrect torque settings or inadequate cleaning of the mating surfaces can all contribute to head gasket failure.

Chemical reactions:

Chemical reactions between different engine fluids can also cause a blown head gasket.

For example, if the wrong type of coolant is used, it can react with the engine’s metal surfaces and cause corrosion, leading to head gasket failure.

Diagnosis of blown head gasket on Kohler engine

Diagnosing a blown head gasket on a Kohler engine can be done through several methods, including:

Physical Inspection:

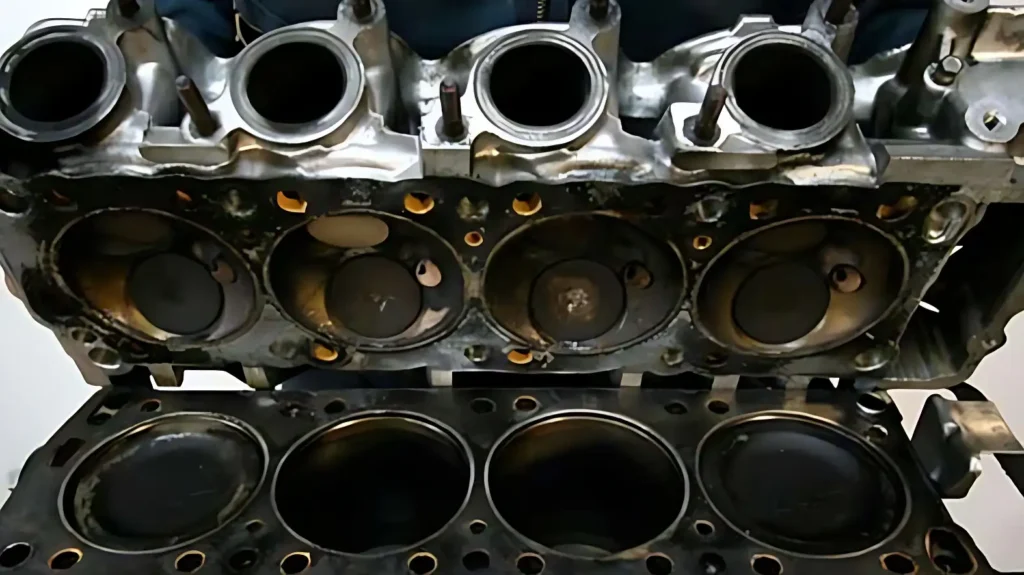

A visual inspection of the engine can reveal signs of a blown head gasket, such as coolant or oil leaks around the head gasket area.

Also, checking the oil dipstick for milky or foamy oil, or inspecting the coolant overflow tank for bubbles, can indicate a blown head gasket.

Compression

Test: A compression test can be used to determine if the head gasket is intact.

A compression gauge is attached to each cylinder, and the compression is measured.

Low compression in one or more cylinders can indicate a blown head gasket.

Leak-Down Test:

A leak-down test is another way to diagnose a blown head gasket. This test involves pressurizing each cylinder and then measuring the amount of air that leaks out.

A high amount of air leakage can indicate a blown head gasket.

Diagnostic Tools:

Kohler engines are equipped with onboard diagnostic tools that can help diagnose a blown head gasket.

These tools can read engine codes and provide data on engine performance, including temperature and coolant levels.

Repair options for the blown head gasket on the Kohler engine

There are some repair options for a blown head gasket on a Kohler engine:

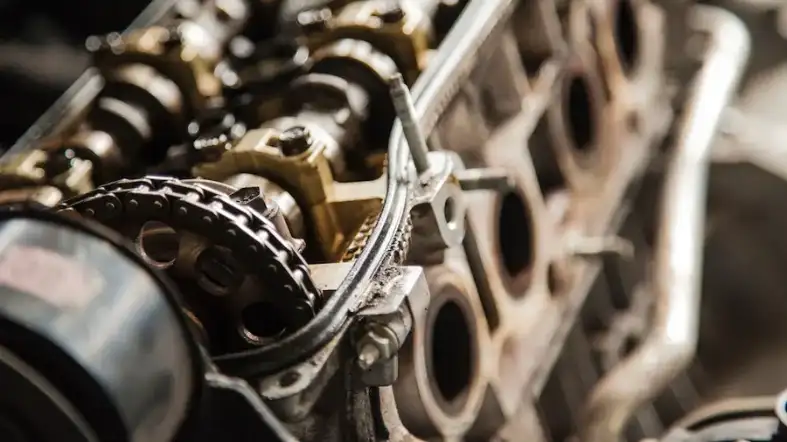

Replacement of the head gasket:

The most common and cost-effective repair option is to replace the head gasket.

This involves removing the cylinder head, replacing the damaged gasket, and reassembling the engine.

Cylinder head repair or replacement:

In some cases, the cylinder head may be damaged beyond repair due to the blown head gasket. In such instances, the cylinder head may need to be replaced.

Engine block repair:

If the blown head gasket has caused significant damage to the engine block, it may require repair or replacement. This is typically the most expensive option.

Chemical sealant:

Some mechanics may use chemical sealant products that can temporarily seal small leaks in the head gasket.

This is not a permanent solution, and the head gasket will need to be replaced eventually.

Engine replacement:

In rare cases where the engine is severely damaged, replacing the entire engine may be the best option.

Prevention Of Blown Head Gasket On Kohler Engine

To prevent a blown head gasket on a Kohler engine, it is important to take the following steps:

Regular maintenance and inspections:

Regular maintenance and inspections are crucial to prevent issues that can lead to a blown head gasket.

Kohler engines require regular oil changes, coolant flushes, and other routine maintenance tasks to keep the engine running smoothly.

Regular inspections can help identify any issues with the engine before they turn into bigger problems.

Promptly addressing engine issues:

If you notice any issues with the engine, such as overheating, loss of power, or unusual sounds, address them immediately.

Ignoring these issues can cause further damage to the engine and increase the risk of a blown head gasket.

Using high-quality and correct coolant:

It is important to use high-quality and correct coolant for the Kohler engine.

Using the wrong type of coolant or low-quality coolant can lead to overheating and eventually a blown head gasket.

Check the owner’s manual to ensure that you are using the correct type of coolant for your engine.

Avoiding overheating:

Ensure that the engine is properly cooled and avoid overworking the engine.

Make sure that the cooling system is in good condition and that the radiator is functioning properly.

Proper installation and torque of the head gasket:

The head gasket is a critical component of the engine and needs to be installed properly.

Ensure that the head gasket is installed correctly and torqued to the manufacturer’s specifications.

This will prevent any leaks and ensure that the engine is functioning properly.

Faqs

How Is A Blown Head Gasket Diagnosed On A Kohler Engine?

A blown head gasket can be diagnosed by visual inspection of the engine for signs of damage, compression, leak down testing to determine the extent of the damage, and other diagnostic tests to pinpoint the issue.

Is It Safe To Operate A Kohler Engine With A Blown Head Gasket?

It is not recommended to drive a Kohler engine with a blown head gasket as it can cause further damage to the engine and lead to more expensive repairs.

How Much Does It Cost To Repair A Blown Head Gasket On A Kohler Engine?

The cost of repairing a blown head gasket on a Kohler engine can vary depending on the extent of the damage, the age and condition of the engine, and the repair option chosen.

The cost can range from a few hundred dollars to several thousand dollars.

Can A Blown Head Gasket On A Kohler Engine Be Prevented?

Regular maintenance and care of the engine can help prevent a blown head gasket on a Kohler engine.

This includes monitoring the engine’s temperature, keeping the cooling system clean and in good working order, performing regular oil changes and tune-ups, and addressing any issues promptly.

Conclusion

A blown head gasket on a Kohler engine can cause significant damage if left unaddressed.

Recognizing the symptoms, such as engine overheating, loss of power, and milky oil or coolant, can help diagnose the issue and prevent further damage.

It is essential to consult with a qualified mechanic to determine the most suitable course of action as repair options vary from head gasket replacement to engine block repair.

Regular maintenance and care can also prevent a blown head gasket from occurring in the first place.