The 6.0 Powerstroke engine is known for its reliability and power, but like any other engine, it can experience issues.

One of the most common problems with the 6.0 Powerstroke engine is a blown head gasket.

A blown head gasket can lead to a variety of symptoms that can affect the performance and longevity of your engine.

In this article, we will discuss the signs and symptoms of a blown head gasket in a 6.0 Powerstroke engine.

6.0 Powerstroke Head Gasket Symptoms

A blown head gasket in a 6.0 Powerstroke engine can cause several symptoms, including

Loss of Power:

This refers to a situation where an engine suddenly loses power, causing a decrease in performance.

It could be due to several reasons, such as a clogged fuel filter, a failing fuel pump, a malfunctioning ignition system, or a faulty sensor.

Loss of power can also occur when the engine is not receiving sufficient fuel or air.

Overheating engine:

An overheating engine occurs when the temperature of the engine rises above normal levels.

It can be caused by several factors such as a malfunctioning cooling system, a damaged radiator, a broken water pump, or low coolant levels.

If an engine overheats, it can lead to severe damage or even complete engine failure.

Poor engine performance:

Poor engine performance refers to a situation where an engine is not functioning optimally.

It could be due to several reasons such as low compression, worn-out spark plugs, a dirty air filter, or a clogged fuel injector.

Poor engine performance can cause issues such as rough idling, misfiring, or reduced acceleration.

Frothy oil:

Frothy oil is a condition where the oil in an engine becomes aerated, resulting in foam or bubbles.

It is typically caused by a failing head gasket or a cracked engine block, allowing coolant to mix with the oil.

Frothy oil can cause significant damage to the engine and must be addressed immediately.

Strange smells from the heating cabinet:

Strange smells from the heating cabinet could indicate a problem with the heating system.

It could be due to a clogged air filter, a malfunctioning blower motor, or a dirty evaporator coil.

These issues can cause poor indoor air quality and potentially harmful conditions for occupants.

Coolant leak:

A coolant leak refers to a situation where the engine coolant is escaping from the cooling system.

It can be caused by several factors such as a damaged radiator, a leaking water pump, or a corroded hose.

A coolant leak can lead to overheating, engine damage, and even engine failure if left unaddressed.

How to Troubleshoot Head Gasket Problems in a 6.0 Powerstroke Engine?

Here are some steps to troubleshoot head gasket problems in a 6.0 Powerstroke engine:

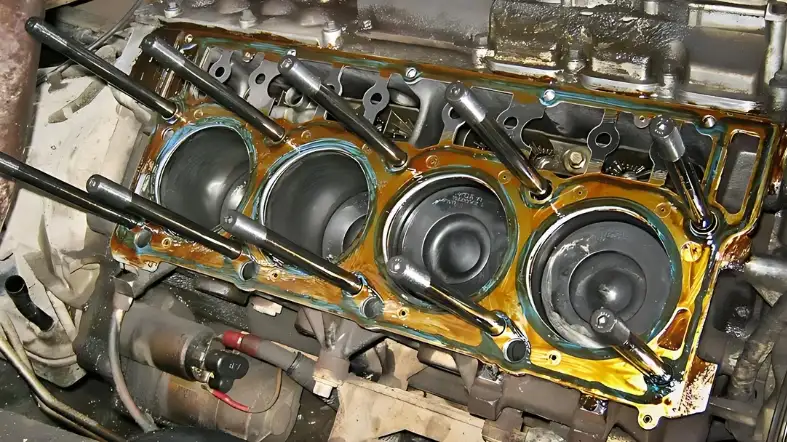

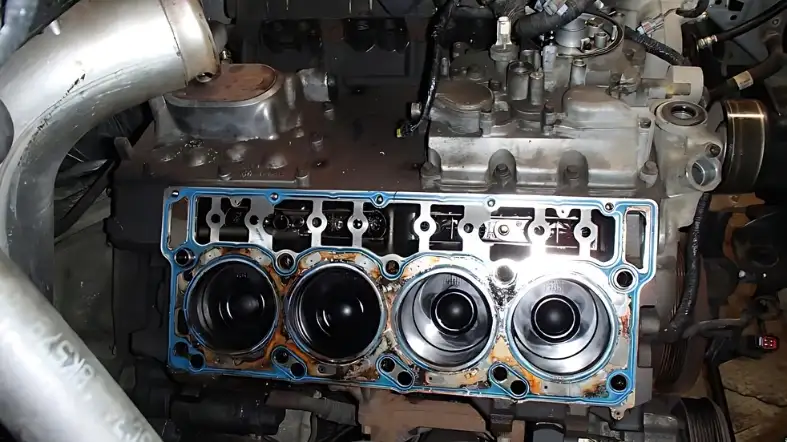

Conduct a Visual Inspection:

The first step is to perform a visual inspection of the engine bay to check for any obvious signs of a head gasket problem, such as coolant leaks or white smoke coming out of the exhaust.

Perform a Compression Test:

A compression test can help you determine the condition of the engine’s internal components.

A drop in compression in one or more cylinders could indicate a blown head gasket.

Check the Oil and Coolant:

If there is a head gasket issue, it can cause the oil and coolant to mix, leading to frothy or milky oil and low coolant levels.

Checking the oil and coolant levels and quality can help you identify if there is a head gasket problem.

Inspect the Radiator:

A damaged or clogged radiator can cause overheating and lead to head gasket problems. Inspect the radiator for any signs of damage or blockages.

Monitor Engine Performance:

Keep an eye on the engine’s performance and note any issues such as reduced power or acceleration, rough idling, or misfiring.

These can be signs of head gasket problems.

Use a Block Tester:

A block tester is a tool that can help detect combustion gases in the coolant, indicating a blown head gasket.

It can be a useful tool in diagnosing head gasket issues.

How to Prevent Head Gasket Failure in a 6.0 Powerstroke Engine?

Here are some measures you can take to prevent head gasket failure in a 6.0 Powerstroke engine:

Install Head Studs

One of the main reasons for head gasket failure in 6.0 Powerstroke engines is the inadequate clamping force provided by head bolts.

Installing high-strength custom head studs can help solve this problem.

The Performance Quotient solution is one such option that provides heat-treated, high-strength Custom 4135 Grade 12.9 Alloy Steel Cylinder Head Studs.

This kit contains the required 20 M14-2.0 x 33.85mm studs, which have a shank outside diameter of 13.44mm and an overall length.

Address Other Common Issues

In addition to head studs, addressing other common issues that affect 6.0 Powerstroke engines can also prevent head gasket failure. These issues include:

- HPOP failure

- Injector stiction

- FICM failure

- Clogging oil coolers

Once these issues are addressed, 6.0 Powerstroke engines become much more reliable.

Regular Maintenance

Regular maintenance is crucial in preventing head gasket failure in a 6.0 Powerstroke engine.

It’s important to replace the oil and oil filter regularly and keep the cooling system functioning correctly.

Keeping the engine clean and checking for leaks can also prevent issues.

Avoid Overheating

Overheating can also cause head gasket failure. Make sure the cooling system is in good condition and operating correctly.

Check the coolant level regularly and top up if necessary. It’s also essential to avoid overloading or overworking the engine.

Use Quality Parts

Using high-quality parts and fluids can also prevent head gasket failure.

Avoid using cheap or substandard parts and fluids, as they can cause issues with the engine. Use parts and fluids recommended by the manufacturer.

The Cost of Replacing Head Gaskets in a 6.0 Powerstroke Engine

Replacing head gaskets in a 6.0 Powerstroke engine can be a costly affair.

The cost of repairing or replacing head gaskets in a 6.0 Powerstroke engine can range from $3,500 to $12,000 or more, depending on the severity of the damage and the extent of the repair needed.

The cost can vary based on the specific repair package you choose.

Some packages include additional upgrades or repairs, such as replacing the water pump, fan clutch, and valve cover gaskets.

The cost can also depend on whether you opt for a rebuild kit or a new long-block engine, as well as the labor costs, which can range from $1,400 to $7,500 or more.

The Pros and Cons of Using Aftermarket Head Gaskets for 6.0 Powerstroke Engines

When it comes to aftermarket head gaskets for 6.0 Powerstroke engines, there are both pros and cons to consider.

Below are some of the key factors to keep in mind.

Pros:

Cost-effective:

Aftermarket head gaskets for 6.0 Powerstroke engines are generally much less expensive than OEM (original equipment manufacturer) parts.

This can be a significant advantage if you are on a tight budget.

Improved performance:

Some aftermarket head gaskets are designed to improve the performance of 6.0 Powerstroke engines.

They may have better sealing properties, higher temperature resistance, or other features that can help your engine run more efficiently.

Availability:

Aftermarket head gaskets are widely available from a range of suppliers, which means you can easily find a replacement when you need one.

Cons:

Quality concerns:

Not all aftermarket head gaskets are created equal, and some may not meet the same quality standards as OEM parts.

This can lead to issues with fit, durability, and performance.

Compatibility issues:

Some aftermarket head gaskets may not be compatible with all 6.0 Powerstroke engines.

It’s important to carefully research the specific make and model of your engine to ensure that the aftermarket gasket you choose will work correctly.

Warranty concerns:

If you are having your engine serviced or repaired by a dealership, using aftermarket parts could void your warranty.

Make sure to check your warranty agreement before making any changes to your engine.

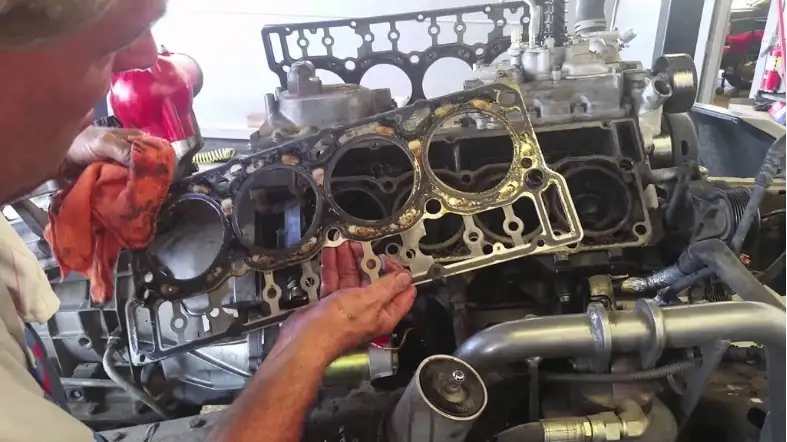

Common Mistakes to Avoid When Replacing Head Gaskets in a 6.0 Powerstroke Engine

Here are some common mistakes to avoid when replacing head gaskets on the Ford 6.0L Power Stroke engine:

Using bolts instead of studs:

Using bolts instead of studs is not recommended, as bolts provide inadequate clamping force and are more likely to result in blown head gaskets.

ARP studs are recommended instead.

Failing to have the heads checked and machined:

It is important to have the heads checked and machined if necessary to ensure proper sealing and prevent future problems.

Neglecting to address other issues:

In addition to head gasket failure, the Ford 6.0L Power Stroke engine is known to have issues with HPOP failure, injector stiction, FICM failure, and clogging oil coolers.

Addressing these issues can prevent future problems.

Failing to replace other components:

When replacing head gaskets, it is important to also replace other components that are known to fail, such as the oil cooler and EGR cooler.

Failure to do so can lead to blown head gaskets in the future.

Neglecting maintenance:

Neglecting maintenance can lead to blown head gaskets and other engine problems.

It is important to stay on top of regular maintenance tasks, such as changing the oil and coolant and replacing filters.

How to Diagnose Head Gasket Failure Early in a 6.0 Powerstroke Engine

Here are some ways to diagnose head gasket failure early:

Check for Coolant Loss:

One of the most common signs of a head gasket failure is coolant loss, which can result in engine overheating.

Look for low coolant levels, as well as leaks around the engine block and cylinder head.

Another sign of coolant loss is a puking or white residue around the coolant overflow cap.

Inspect the Oil:

Another sign of head gasket failure is the presence of coolant in the engine oil.

If you notice milky, white oil on the dipstick, this is a clear sign of a head gasket leak.

Look for White Smoke:

When white smoke comes out of the exhaust, this is another indication of head gasket failure.

This is due to coolant leaking into the combustion chamber and burning with the fuel.

White smoke can also indicate other issues, such as a damaged turbocharger, so it’s important to have a professional diagnose the problem.

Check for Compression Loss:

A compression test can help determine if there is a leak in the head gasket.

If the compression is low in one or more cylinders, this can be an indication of a head gasket leak.

Look for Other Common Issues:

The 6.0 Powerstroke engine is known to have other issues that can mimic head gasket failures, such as clogged oil coolers or injector problems.

It’s important to have a professional mechanic diagnose the problem before jumping to conclusions.

Consider Upgrading the Head Bolts:

Upgraded head bolts can provide better clamping force and prevent head gasket failures in the future.

One popular solution is the use of custom 4135 grade 12.9 alloy steel cylinder head studs, which can help prevent head gasket failure due to the stretching of the cylinder head bolts.

Frequently Asked Question

What Causes Head Gasket Failure In A 6.0 Powerstroke Engine?

Answer: Head gasket failure can be caused by a variety of factors, including overheating, excessive engine stress, poor quality coolant, and normal wear and tear.

What Are The Most Common Symptoms Of A Blown Head Gasket In A 6.0 Powerstroke Engine?

Answer: The most common symptoms of a blown head gasket in a 6.0 Powerstroke engine include coolant leaks, overheating, poor engine performance, white smoke from the exhaust, and frothy or milky oil.

Can A Blown Head Gasket Cause Other Engine Problems In A 6.0 Powerstroke Engine?

Answer: Yes, a blown head gasket can cause several other engine problems, such as loss of power, rough idling, misfires, and reduced fuel efficiency.

How Can I Diagnose A Head Gasket Problem In My 6.0 Powerstroke Engine?

Answer: You can diagnose a head gasket problem by checking for coolant leaks, performing a compression test, inspecting the oil and coolant levels, and using a block tester.

Is It Possible To Repair A Blown Head Gasket In A 6.0 Powerstroke Engine, Or Does It Need To Be Replaced?

Answer: In most cases, a blown head gasket will need to be replaced.

However, some minor leaks can be repaired using sealants or other temporary fixes.

Can Regular Maintenance Help Prevent Head Gasket Problems In A 6.0 Powerstroke Engine?

Answer: Yes, regular maintenance can help prevent head gasket problems by ensuring the engine is properly lubricated, the coolant is at the correct levels and quality, and the engine is not under excessive stress.

Can I Drive My 6.0 Powerstroke Engine With A Blown Head Gasket?

Answer: It is not recommended to drive your 6.0 Powerstroke engine with a blown head gasket as it can cause significant damage to the engine and result in costly repairs.

Conclusion:

A blown head gasket in a 6.0 Powerstroke engine can cause serious damage if left untreated.

It’s important to be aware of the symptoms and to take action as soon as possible.

If you notice any of the signs discussed in this article, it’s recommended to have your engine inspected by a professional mechanic.

With prompt attention and proper repairs, you can keep your 6.0 Powerstroke engine running smoothly and efficiently for years to come.