Are you experiencing issues with your Screamin Eagle Cam Plate?

You’re not alone. Many Harley-Davidson riders have encountered problems with their cam plate, which can lead to costly repairs or even engine failure.

In this blog post, we’ll explore the common issues with Screamin Eagle Cam Plates, the potential causes, and the best solutions to keep your bike running smoothly.

So if you own a Harley-Davidson with a Screamin Eagle Cam Plate, keep reading to learn how to avoid potential headaches down the road.

Screamin Eagle Cam Plate Issues

Screamin Eagle cam plate issues can cause engine damage, including catastrophic failure. Symptoms include oil leaks, loss of power, and abnormal engine noise. Immediate inspection and replacement are crucial to prevent further damage.

Common Issues with Screamin Eagle Cam Plates

Cam Plate Wear and Damage

One of the most common issues with Screamin Eagle Cam Plates is wear and damage.

Over time, the cam plate can wear down, resulting in reduced performance and eventually complete failure.

This can be caused by a variety of factors, including improper installation, poor maintenance, or simply general wear and tear.

Additionally, if the cam plate is not properly lubricated, it can overheat and cause damage to the plate and the engine.

Poor Performance

Another issue that riders may encounter with Screamin Eagle Cam Plates is poor performance. While the cam plates are designed to improve performance, they may not always deliver the desired results.

This can be caused by a variety of factors, including improper installation, a mismatched cam, or a poorly tuned engine.

It is important to ensure that the cam plate is properly matched to the engine and that the engine is properly tuned to maximize performance.

Noise and Vibration

Screamin Eagle Cam Plates can also be noisy and cause vibration. This can be caused by a variety of factors, including improper installation, a mismatched cam, or worn components.

If the cam plate is not properly installed or matched to the engine, it can cause excessive noise and vibration, which can be both annoying and potentially damaging to the engine.

Compatibility Issues

Finally, riders may also encounter compatibility issues with Screamin Eagle Cam Plates.

These cam plates are designed for specific Harley-Davidson models and may not be compatible with all models or aftermarket components.

It is important to ensure that the cam plate is compatible with your specific model and any aftermarket components that you may have installed.

Symptoms of a Failing Screamin Eagle Cam Plate

Symptoms of a failing Screamin eagle cam plate:

Engine Misfires

One of the most common symptoms of a failing Screamin Eagle cam plate is engine misfire.

Misfires occur when the cam plate fails to synchronize the timing of your camshaft and crankshaft properly, causing your engine to miss a beat or fire out of sequence.

If you notice your engine sputtering or hesitating, it’s a sign that your cam plate may be failing.

Loss of Power

Another common symptom of a failing cam plate is a loss of power. When the timing of your camshaft and crankshaft is out of sync, it can cause a loss of power in your engine,

Which can be particularly noticeable when you’re accelerating. If you find that your motorcycle is struggling to gain speed, it could be a sign that your cam plate is failing.

Engine Noise

A failing cam plate can also cause your engine to make unusual noises. You may hear knocking or tapping sounds, which can indicate that the camshaft and crankshaft are not synchronized properly.

If you notice any unusual sounds coming from your engine, it’s important to get it checked out by a professional mechanic as soon as possible.

Engine Stalling

If your cam plate is severely damaged, it can cause your engine to stall or fail to start altogether.

This is because the cam plate plays a crucial role in the timing and firing of your engine, and if it fails, your engine may not be able to operate at all.

If your motorcycle is stalling frequently or refusing to start, it’s a clear indication that there’s a problem with your cam plate.

Causes of Cam Plate Issues in Screamin Eagle Engines

Improper Installation

One of the most common causes of cam plate issues in Screamin Eagle Engines is improper installation. When the cam plate is not installed correctly, it can cause a host of problems.

For instance, if the cam plate is not torqued down correctly, it can cause the plate to warp or bend, leading to oil pressure problems.

Additionally, if the plate is not properly aligned, it can cause excessive wear on the bearings and the camshaft, leading to premature failure.

Lack of Maintenance

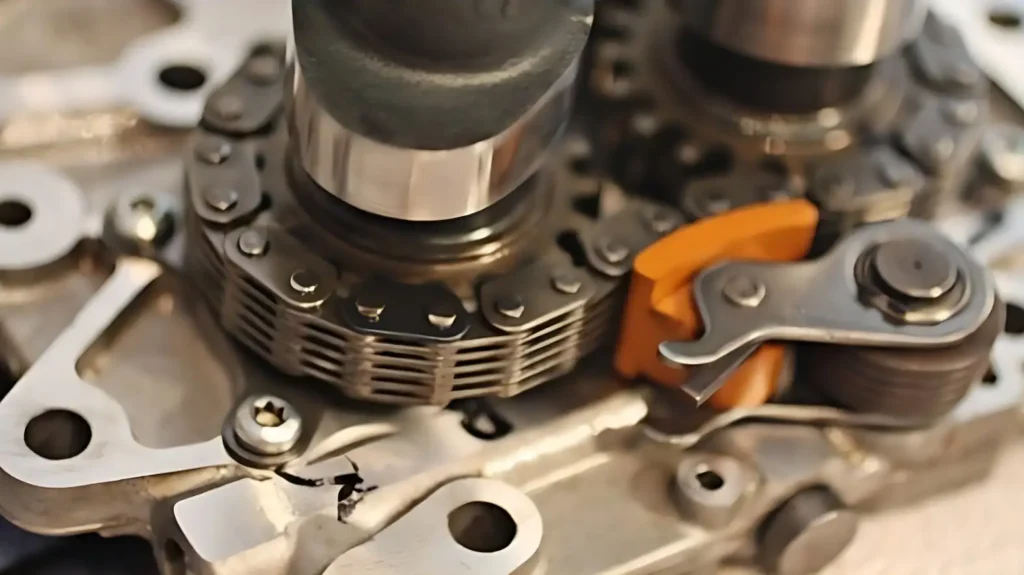

Another common cause of cam plate issues in Screamin Eagle Engines is a lack of maintenance. The cam plate and oil pump require regular maintenance to function correctly.

Failure to perform routine maintenance, such as oil changes and filter replacements, can lead to clogs and debris buildup in the oil pump, which can cause low oil pressure and other issues.

Upgraded Components

While upgrading components can improve the performance of the engine, it can also lead to cam plate issues. When upgrading components, it’s essential to ensure that all parts are compatible with each other.

If parts are not compatible, it can cause excessive wear and tear on the cam plate and other components, leading to premature failure.

Excessive Heat

Harley Davidson’s Screamin Eagle Engines generate a significant amount of heat. If the engine is not adequately cooled, it can cause the cam plate to warp or bend.

Additionally, if the oil pump is not correctly lubricated, it can cause excessive wear on the bearings, leading to premature failure.

Manufacturing Defects

Although rare, manufacturing defects can also cause cam plate issues in Screamin Eagle Engines.

If the cam plate or other components are not manufactured to the correct specifications, it can cause premature failure and other problems.

Repairing A Faulty Screamin Eagle Cam Plate

Here is a step-by-step guideline on how to repair or replace a faulty cam plate of Screamin eagle:

Disassembling the Cam Plate:

To disassemble the cam plate, the first step is to remove it from the engine.

This requires draining the oil, removing the primary cover, and taking out the clutch assembly.

Once the cam plate is accessible, carefully remove the bolts holding it in place and lift it out of the engine.

Once the cam plate is removed, separate all the components attached to it, including the camshaft, bearings, and oil pump. This step requires precision and care to avoid damaging any of the parts.

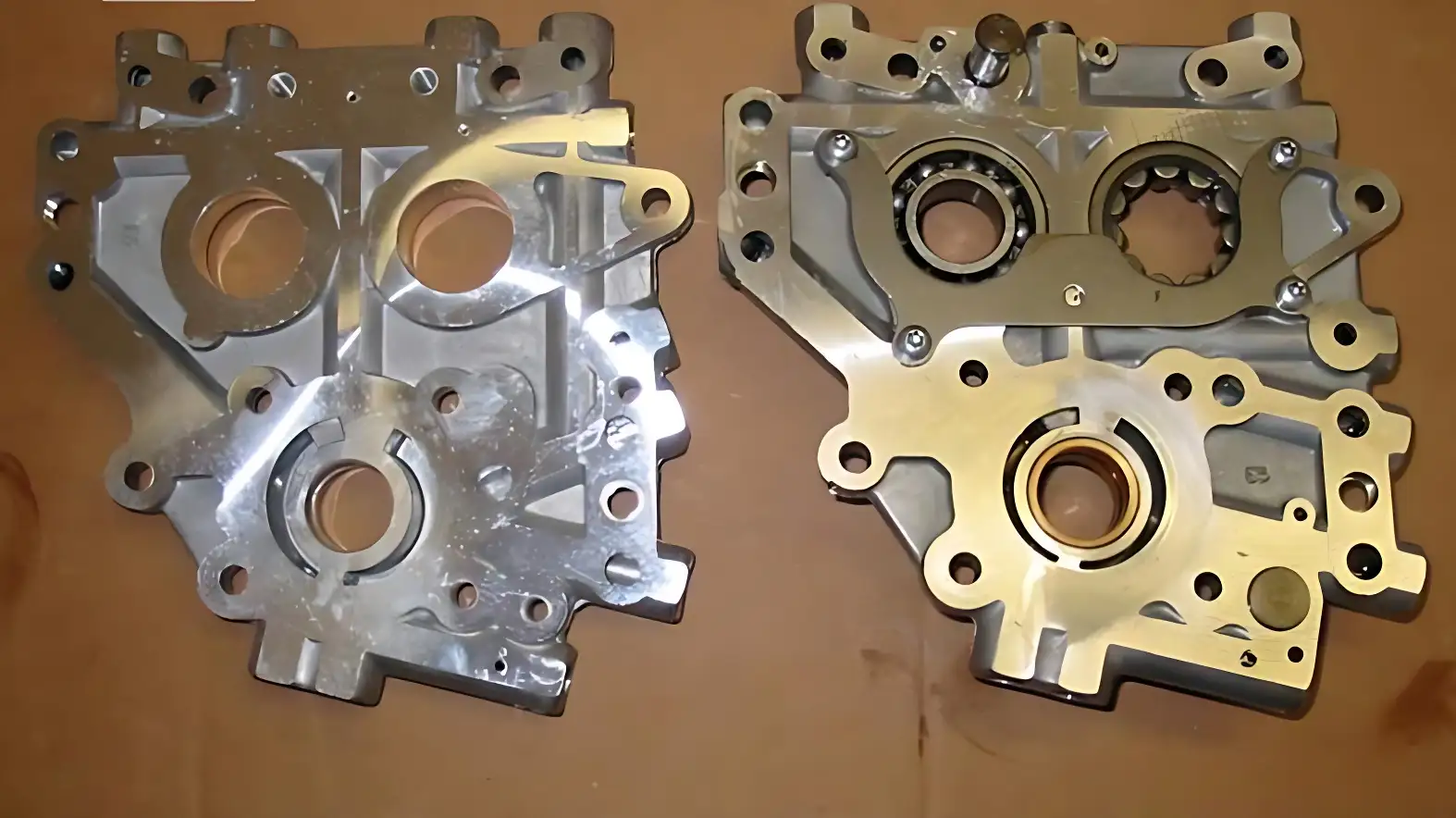

Inspecting the Cam Plate for Damage:

Once the cam plate is disassembled, it is important to thoroughly inspect it for any signs of wear or damage.

This includes checking for cracks, chips, or excessive wear on the bearing surfaces.

It is also important to check the oil passages for any signs of blockage or damage. If any damage is found, the cam plate will need to be replaced.

Cleaning the Cam Plate:

After the cam plate has been inspected, it is important to clean it thoroughly.

This involves using a degreaser to remove any dirt or grime that may have accumulated on the cam plate.

Once the degreaser has been applied, use a soft-bristled brush to scrub the cam plate and remove any remaining debris.

Be sure to rinse the cam plate thoroughly and dry it completely before moving on to the next step.

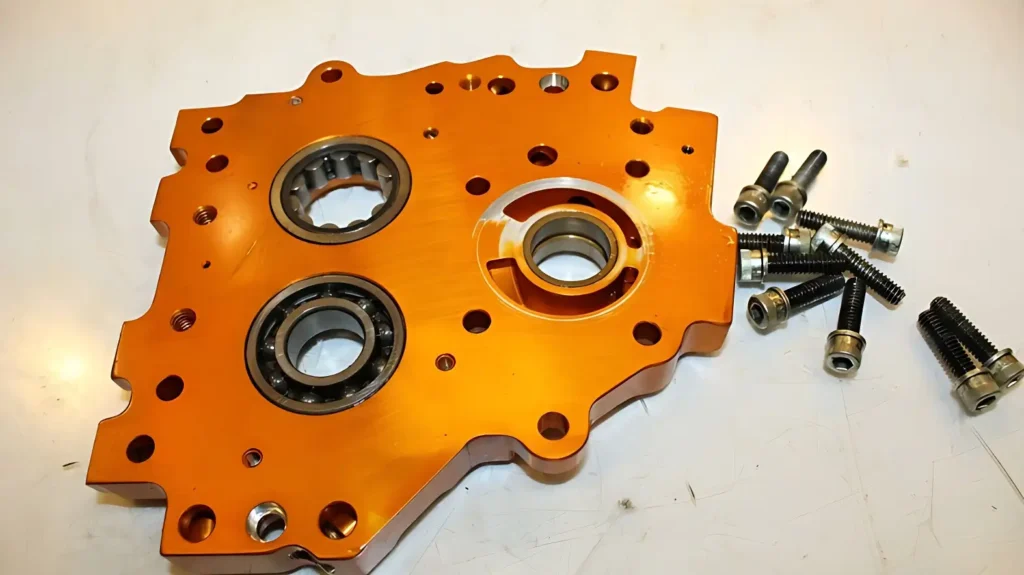

Replacing the Cam Plate Bearings:

If the cam plate bearings show any signs of wear or damage during the inspection, they will need to be replaced.

To replace the bearings, use a bearing puller to remove the old bearings from the cam plate.

Once the old bearings have been removed, clean the bearing bores thoroughly and install new bearings. Use a bearing driver to carefully press the new bearings into place.

Installing a New Cam Plate:

If the cam plate cannot be repaired, it will need to be replaced.

To install a new cam plate, carefully place it into the engine and torque the bolts to the manufacturer’s specifications.

Reinstall the camshaft, bearings, and oil pump, being careful not to damage any of the parts during installation.

Reassembling the Engine:

Once the cam plate has been repaired or replaced, it is time to reassemble the engine.

This involves reinstalling the primary cover, clutch assembly, and other components that were removed to access the cam plate.

Be sure to follow the manufacturer’s instructions and torque specifications for each component to ensure proper installation.

Testing the Repaired Cam Plate:

After the engine has been reassembled, it is important to test the repaired cam plate to ensure it is functioning properly.

Start the engine and listen for any unusual noises or vibrations. Check the oil pressure and make sure it is within the manufacturer’s specifications.

Finally, take the motorcycle for a test ride to ensure the cam plate is performing as expected.

How to Prevent Screamin Eagle Cam Plate Issues?

Choose the Right Parts and Installation Method

The first step in preventing cam plate issues is to ensure that you’re using the correct parts and installation method.

When it comes to Screamin Eagle cam plates, there are two main types: hydraulic and mechanical.

Hydraulic cam plates require a special hydraulic installation tool, while mechanical cam plates require a different installation method.

It’s crucial to use the right tools and follow the manufacturer’s instructions carefully to prevent issues from arising.

Monitor Cam Plate Wear and Tear

Another critical step in preventing cam plate issues is to monitor the wear and tear of the cam plate regularly. Over time, the cam plate can wear down, causing issues with valve timing and performance.

Regular inspections of the cam plate can help you catch any wear and tear early on, allowing you to address the issue before it causes more significant problems.

It’s also essential to replace the cam plate if it shows signs of excessive wear and tear.

Use High-Quality Oil and Proper Maintenance

Using high-quality oil and performing proper maintenance on your motorcycle is another key to preventing cam plate issues.

Dirty or low-quality oil can cause excessive wear and tear on the cam plate, leading to performance issues and potential damage.

Regular oil changes and proper maintenance can help keep your cam plate and engine running smoothly.

Avoid Over-revving and Extreme Conditions

Finally, it’s crucial to avoid over-revving your engine and subjecting it to extreme conditions.

Over-revving can cause excessive wear and tear on the cam plate and other engine components, leading to issues down the road.

Similarly, extreme weather conditions, such as extreme heat or cold, can also cause issues with the cam plate and other engine components.

Avoiding these conditions and being mindful of your engine’s performance can help prevent cam plate issues.

FAQs

The Old Rear Cam Sprocket Had A Spacer And A Shim Behind It. The New Set Up Required Purchase Of A Bag Of New Spacers. What Should I Do?

It is necessary to use the new spacers provided with the Screamin’ Eagle 25284-08 Billet Hybrid Cam Plate installation kit.

These new spacers are required because they are designed to work with the new cam plate setup.

What Is The Difference Between The Stock Oil Pump And The SE Oil Pump Upgrade For A Harley-Davidson Bike?

The SE oil pump upgrade (part number 26037-06) is a higher flow oil pump than the stock oil pump on pre-2007 Harley-Davidson motorcycles.

The SE oil pump upgrade increases oil flow by 8% and scavenging by 22% over the pre-2007 stock pump.

The hydraulic cam plate kit does come with an oil pump that is stock on 2007 and later models, which is higher flow than the pre-2007 spring tensioner bikes.

What Are Some Of The Most Frequent Problems Experienced By Owners Of The Screamin’ Eagle 110 Engine?

Some of the most frequent problems experienced by owners of the Screamin’ Eagle 110 engine include oil leaks, overheating, lifter noise, and cam chain tensioner issues.

However, solutions for these problems can be found through proper maintenance, upgrading to higher-quality parts, or seeking professional repair services.

What Was The Problem With The Early Twin Cam 88 Engines?

The early twin cam 88 engines had cam chains that were made with sharp ridges on the outer plates that quickly ate away at the plastic tensioner.

This issue, combined with the spring-loaded cam chain tensioner, caused significant problems for these early twin cam models.

What Are The Differences Between The Screamin’ Eagle® Billet Cam Support Plate And The Stock Plate For Harley-Davidson Bikes?

The Screamin’ Eagle® Billet Cam Support Plate is made of soft aluminum that is surface hardened, which makes it more prone to wear than the stock plate made of a tough casting mix.

Specifically, the oil pump Gerotors rubbing on the cam plate can cause quicker wear.

However, the Screamin’ Eagle® Billet Cam Support Plate comes with a high-volume oil pump, which is stock in the 96″ and larger motors of today’s bikes.

Conclusion

The Screamin Eagle Cam Plate can be a great upgrade for Harley-Davidson riders looking to increase their bike’s power.

However, as with any upgrade, it’s important to be aware of potential issues that can arise.

By keeping an eye out for common issues like premature wear or improper installation, and taking steps to address them promptly, you can ensure that your cam plate upgrade provides the desired performance boost for many miles to come.

So, if you’re experiencing any issues with your Screamin Eagle Cam Plate, don’t hesitate to seek expert help and get back on the road with confidence!