Replacing the crankshaft position sensor in your car may seem like a quick and easy fix, but it can lead to a variety of problems if not done correctly.

Today we will give a clear insight into what causes problems after replacing the crankshaft position sensor.

Problems After Replacing Crankshaft Position Sensor

If problems persist after replacing the crankshaft position sensor, it could indicate issues with the wiring, connector, or ECU.

Check for damaged or corroded wires, ensure a secure connection, and consider diagnosing the ECU.

Common Causes of Problems After Replacing Crankshaft Position Sensor

Here are some of the common causes of problems after replacing the crankshaft position sensor:

Faulty or Defective Sensor

The first cause of problems after replacing the crankshaft position sensor may be that the new sensor is faulty or defective.

The sensor may have been damaged during installation, or it may have been manufactured poorly .

In either situation, the sensor will misinform the engine control module (ECM), triggering engine failure.

Wrong Type of Sensor

Another cause of problems after replacing the crankshaft position sensor may be that the wrong type of sensor was installed.

There are different types of sensors, each designed to work with a specific engine make and model.

If the wrong sensor is installed, it will not provide accurate information to the ECM, leading to engine malfunction.

Incorrect Installation

Sometimes, problems arise after replacing the crankshaft position sensor due to incorrect installation.

If the sensor is not installed properly, it will not provide accurate information to the ECM, leading to engine malfunction.

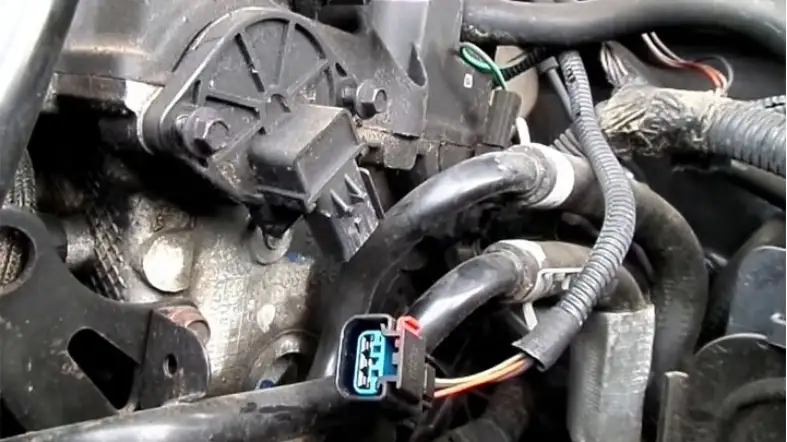

Damaged Wiring or Connectors

Another possible cause of problems after replacing the crankshaft position sensor is damaged wiring or connectors.

The wiring or connectors may have been damaged during installation or due to wear and tear.

Damaged wiring or connectors can cause the sensor to malfunction, leading to engine problems.

Other Related Issues

Finally, problems after replacing the crankshaft position sensor may be caused by other related issues.

For example, if the ECM is faulty, it may not be able to receive accurate information from the sensor, leading to engine malfunction.

Other related issues may include problems with the fuel system, ignition system, or other engine components.

How to diagnose and fix problems after replacing the crankshaft position sensor?

Here are some ways to diagnose and fix such problems:

Scan for Error Codes

The first step in diagnosing problems after replacing the crankshaft position sensor is to scan the engine control module (ECM) for error codes.

Error codes can assist diagnose the issue.

Check Sensor Wiring and Connectors

Next, check the sensor wiring and connectors for any signs of damage or wear. If the wiring or connectors are damaged, repair or replace them as necessary.

Test the Sensor

Test the sensor using a multimeter to ensure it is providing accurate readings. Check the sensor’s performance by comparing readings to manufacturer specifications.

Correctly Install the Sensor

Reinstall the sensor if it wasn’t installed properly. Secure wiring and connectors.

Repair Damaged Wiring or Connectors

If the wiring or connectors are damaged, repair or replace them as necessary. Be sure to properly secure the wiring and connectors.

Address Other Related Issues

If the problem is related to other engine components, such as the fuel system or ignition system, address those issues as needed.

Reset the ECM

After making any repairs or replacements, reset the ECM to clear any error codes and ensure the engine is functioning properly.

By following these steps, you can diagnose and fix problems that may arise after replacing the crankshaft position sensor.

How to Replace the Crankshaft Position Sensor properly?

Here’s a step-by-step guideline to help you replace the crankshaft position sensor properly:

Locate the sensor:

Find the crankshaft position sensor first. The sensor is typically installed on the engine block or the transmission case.

Disconnect the battery:

Before starting any work, it is essential to disconnect the battery to prevent any electrical accidents.

Remove the sensor:

The crankshaft position sensor is typically held in place with one or two bolts. Remove the bolts using a socket wrench, and gently pull the sensor out of its socket.

Disconnect the electrical connector:

Once you have removed the sensor, disconnect the electrical connector attached to it.

Install the new sensor:

Put the replacement sensor where the old one was. Verify that the sensor is positioned correctly, and then snug the bolts holding it in place.

Reconnect the electrical connector:

Connect the electrical connector to the new sensor. Make sure the connection is secure.

Reconnect the battery: Finally, reconnect the battery and start the engine to test the new sensor.

How to Prevent Problems When Replacing the Crankshaft Position Sensor

Here are some steps that you can take to prevent cranshaft problems after replacing:

Choose the Correct Sensor:

Selecting the right sensor for the engine model is critical. The improper sensor might affect the engine performance.

Engine sensors are specified by the manufacturer.

Follow Manufacturer Instructions:

It is crucial to follow the manufacturer’s instructions for removing and installing the sensor.

Make sure to follow the proper steps and use the appropriate tools.

Failure to follow the instructions could result in the incorrect installation or damage to the sensor.

Inspect Wiring and Connectors:

Before installing the new sensor, inspect the wiring and connectors for any signs of damage or wear.

Replace any damaged wiring or connectors to prevent issues with the new sensor. Make sure to check the wiring and connectors that connect to the sensor and to the power source.

Handle the Sensor with Care:

Handle the sensor with care during installation to avoid damaging it. Avoid applying excessive force, which can damage the sensor or its wiring.

Carefully install the sensor according to the manufacturer’s instructions.

Test the Sensor:

After installing the sensor, test it using a multimeter to ensure it is providing accurate readings.

Compare the readings to the manufacturer’s specifications to verify that the sensor is functioning correctly.

Testing the sensor ensures that it is properly installed and functioning as intended.

Perform Regular Maintenance

Perform regular maintenance on the engine and related components to prevent issues with the crankshaft position sensor.

This includes regularly checking and replacing worn or damaged parts and ensuring that the engine is properly tuned.

By following these steps, you can help prevent problems when replacing the crankshaft position sensor and ensure that the engine is operating smoothly and efficiently.

Frequently Asked Question

What Should I Do If My Car Still Doesn’t Start After Replacing The Crankshaft Position Sensor?

If the car still doesn’t start after replacing the sensor, make sure that the sensor is properly installed and wired.

Check if there are other issues with the ignition or fuel system. If necessary, seek help from a mechanic.

Why Is My Car’s Engine Stalling Or Idling Roughly After Replacing The Crankshaft Position Sensor?

If the engine is stalling or idling roughly, it could be due to an incorrectly installed sensor.

Check if the sensor is correctly installed and if the wiring is correct. Also, check if there are other issues with the ignition or fuel system.

Why Is My Car’s Check Engine Light Still On After Replacing The Crankshaft Position Sensor?

If the check engine light is still on after replacing the sensor, it could be due to an incorrectly installed sensor.

Check if the sensor is installed correctly and if the wiring is correct. Also, check if there are other issues with the engine or emissions system.

Why Is My Car’s Acceleration Delayed Or Sluggish After Replacing The Crankshaft Position Sensor?

If the acceleration is delayed or sluggish, it could be due to an incorrectly installed sensor.

if the sensor is installed correctly and if the wiring is correct. Also, check if there are other issues with the fuel or ignition system.

Why Is My Car’s Fuel Efficiency Worse After Replacing The Crankshaft Position Sensor?

If the fuel efficiency is worse after replacing the sensor, it could be due to an incorrectly installed sensor.

Check if the sensor is installed correctly and if the wiring is correct. Also, check if there are other issues with the fuel system or engine.

Why Is My Car’s RPM Fluctuating Or Inconsistent After Replacing The Crankshaft Position Sensor?

If the RPM is fluctuating or inconsistent, it could be due to an incorrectly installed sensor.

Check if there are other issues with the engine or fuel system.

Why Is My Car’s Timing Belt Or Chain Making Unusual Noises After Replacing The Crankshaft Position Sensor?

If the timing belt or chain is making unusual noises, it could be due to an incorrectly installed sensor.

Check if there are other issues with the engine’s timing or mechanical components.

Wrap Up

While it’s never ideal to have problems with your vehicle, it’s important to remember that these issues are not insurmountable.

With the right guidance and expertise, you can overcome the challenges and get back on the road safely and confidently.