When an engine is running, the camshaft rotates, opening and closing the engine’s valves.

The camshaft lobes that come in contact with the valves can become worn, resulting in poor engine performance and potentially causing permanent engine damage if not addressed.

Repairing worn cam lobe pairs is crucial to maintaining a well-functioning engine, but the process can be complex and require specialized tools and equipment.

In this guide, we will explore the answer to how to fix a worn cam lobe pair.

How To Fix Worn Cam Lobe Pairs?

Here are the steps involved in repairing worn cam lobe pairs:

Diagnosis of worn cam lobe pairs:

Check the symptoms of worn cam lobe pairs, such as engine misfiring, reduced power, unusual noises, or poor fuel economy.

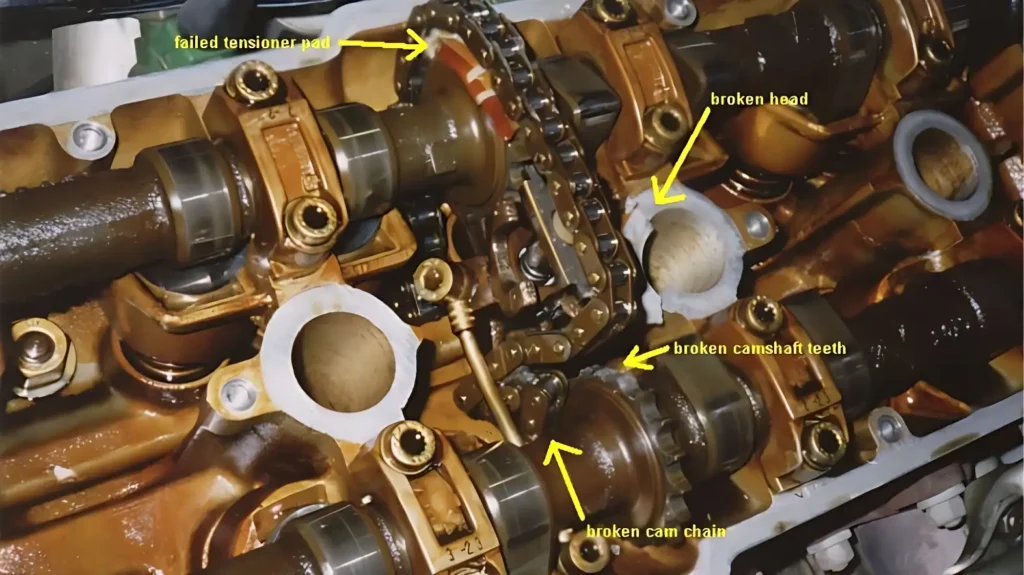

Inspect and measure the camshaft lobes to identify worn lobes, pitting, scoring, or other types of damage.

Determine the cause of the damage, such as oil starvation, incorrect valve lash adjustment, or abrasive particles in the engine oil, and address it if possible.

Preparation for repair:

Remove the camshaft from the engine carefully, following the manufacturer’s recommendations, and label the cam lobes for future reference.

Clean the camshaft thoroughly using a degreaser, hot water, and a soft brush or cloth. Do not use abrasive materials that can damage the camshaft surface or bearings.

Remove the worn cam lobes using a lathe, grinder, or specialized cutting tool.

Repair options:

Grinding of camshaft lobes involves removing a thin layer of material from the worn lobes to restore their original shape and size.

It’s suitable for mild to moderate camshaft wear or damage and requires specialized grinding equipment and experienced operators.

Welding of worn lobes and subsequent grinding involves applying a layer of metal to the worn lobes using a welding process and then shaping them back to their original size and shape using a grinder.

Replacement of the camshaft involves removing the worn camshaft and installing a new one.

Selection of repair option:

Consider the cost, downtime, and availability of parts and equipment for each repair option.

Evaluate the extent of damage by measuring the camshaft lobes, inspecting the bearings, and checking the valve clearance.

Assess the repair quality and longevity by consulting with experienced mechanics or camshaft manufacturers.

Repairing camshaft lobes by grinding:

Use specialized equipment such as a camshaft grinder or a CNC machine to remove a precise amount of material from the worn cam lobes.

Follow the manufacturer’s specifications for the grinding wheel, coolant, and feed rate to achieve the correct lobe profile and surface finish.

Measure the camshaft after grinding using micrometers, dial indicators, or laser scanners to ensure proper dimensions are achieved.

Welding and grinding of worn cam lobes:

Use specialized welding equipment such as TIG or plasma arc welding to apply a layer of metal to the worn cam lobes.

Grind the welded lobes back to their original size and shape using a camshaft grinder or a CNC machine.

Measure the camshaft after repair using micrometers, dial indicators, or laser scanners to ensure proper dimensions are achieved.

Replacement of camshaft:

Source a replacement camshaft from a reputable supplier that meets or exceeds the manufacturer’s specifications.

Install the replacement camshaft following the manufacturer’s recommendations, and use new gaskets, seals, and bearings as needed.

Follow the break-in process for the new camshaft, such as priming the oil pump, using a specific type of engine oil, and running the engine at low speeds and loads for a certain period.

Reinstallation of camshaft:

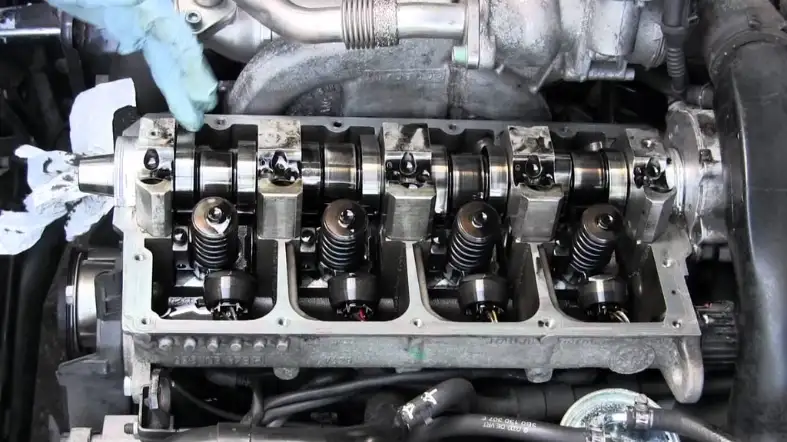

Clean and lubricate engine components such as the cylinder head, lifters, and pushrods before reassembling them.

Properly reinstall the camshaft using new bolts, nuts, or washers as recommended by the manufacturer.

Verify camshaft timing and operation using a timing light, compression tester, or other diagnostic tools to

ensure proper engine performance.

Symptoms Of Worn Cam Lobe Pairs

Here are some common symptoms of worn cam lobe pairs:

Engine misfiring:

Misfiring is a common symptom of worn cam lobes because the lobes control the opening and closing of the valves, which are essential for the combustion process.

Misfiring can occur when the valves are not opening or closing properly due to uneven camshaft wear, resulting in incomplete combustion or fuel mixture problems.

Reduced power:

Worn cam lobes can cause a reduction in engine power by affecting the valve lift, timing, and duration, which all play a crucial role in the engine’s performance.

The reduction in power can result in slower acceleration, decreased towing or hauling capacity, or difficulty climbing hills.

Unusual noises:

Worn cam lobes can produce ticking, tapping, or clicking sounds, which can be caused by the excessive lash between the camshaft and the rocker’s arm, or by the metal-to-metal contact between the camshaft and the lifter.

The noises can be more noticeable at idle or under load and can indicate that the cam lobes are not providing the correct lift or duration.

Poor fuel economy:

Worn cam lobes can cause the engine to consume more fuel than usual, resulting in decreased fuel economy and higher operating costs.

The increased fuel consumption can occur because the valves are not opening and closing at the correct times or are not opening fully, causing incomplete combustion and a higher demand for fuel.

Engine vibration:

Worn cam lobes can cause the engine to vibrate or shake because the camshaft is not providing the correct lift or duration, resulting in an unbalanced engine.

The vibration can be felt through the steering wheel, pedals, or seats and can indicate that the engine is not running smoothly.

Check engine light:

A malfunction in the engine control system caused by worn cam lobes can trigger the check engine light to illuminate the dashboard.

The check engine light can indicate a range of issues, from minor to severe, and should be diagnosed promptly to prevent further damage to the engine.

Rough idle:

Worn cam lobes can cause the engine to idle roughly or unevenly because the valves are not opening and closing at the correct times or are not opening fully.

The rough idle can make the vehicle feel unstable or uncomfortable to drive and can indicate that the engine is not running smoothly.:

What are the different ways you can repair worn cam lobe pairs?

There are different ways to repair worn cam lobe pairs, depending on the severity and type of wear, as well as the engine and camshaft design.

Here are some of the common methods:

Camshaft regrinding:

This method involves removing a thin layer of metal from the worn cam lobe surface to restore the original profile and lift.

Camshaft regrinding can be done by a professional machine shop or camshaft manufacturer using specialized equipment and techniques.

This method is suitable for mild to moderate wear and can be less expensive than replacing the camshaft.

Camshaft replacement:

If the camshaft wear is severe or if the lobes are damaged beyond repair, camshaft replacement may be necessary.

Camshaft replacement involves removing the old camshaft and installing a new one that is compatible with the engine and valve train.

This method is more expensive than regrinding but can provide a longer-lasting solution and improved engine performance.

Camshaft lobe welding:

This method involves adding metal to the worn cam lobe surface using a welding process, then grinding the surface to restore the original profile and lift.

Camshaft lobe welding requires specialized welding equipment and skills and is typically done by a professional machine shop or camshaft manufacturer.

This method can be suitable for moderate to severe wear but may not be recommended for some camshaft materials or designs.

Camshaft sleeve installation:

This method involves installing a sleeve over the worn camshaft lobe to provide a new surface for the lifter or rocker’s arm to ride on.

Camshaft sleeve installation requires precise machining and fitting of the sleeve and may require modifying the valve train components to accommodate the new diameter.

This method can be suitable for mild to moderate wear and can be less expensive than replacing the camshaft.

Engine replacement:

In some cases, particularly for older or high-mileage engines, it may be more cost-effective to replace the entire engine rather than repairing or replacing the worn camshaft.

Engine replacement involves removing the old engine and installing a new or remanufactured engine that is compatible with the vehicle.

This method can provide a fresh start for the engine and may include new or improved components that can improve performance and reliability.

How can you Test and monitor the problem?

Here are some ways to test and monitor the problem:

Compression test:

A compression test can help determine if the cam lobes are worn by measuring the pressure inside the cylinders during cranking or running the engine.

Low compression in one or more cylinders can indicate that the valves are not opening or closing correctly due to worn cam lobes.

Vacuum gauge test:

A vacuum gauge test can help detect worn cam lobes by measuring the vacuum level in the intake manifold at idle and during acceleration.

Low vacuum readings or fluctuating vacuum can indicate that the valves are not opening or closing correctly due to worn cam lobes.

Oil pressure test:

An oil pressure test can help diagnose worn cam lobes by measuring the oil pressure in the engine at different RPMs.

Low oil pressure or fluctuating oil pressure can indicate that the camshaft is not receiving enough oil lubrication, which can cause wear and damage to the lobes.

Visual inspection:

A visual inspection of the camshaft and valve train components can help identify signs of wear or damage, such as pitting, scuffing, or uneven wear on the cam lobes.

A borescope or endoscope can be used to inspect the camshaft lobes and journals without removing the camshaft.

OBD-II scanner:

An OBD-II scanner can help diagnose worn cam lobes by reading the engine control module (ECM) codes and identifying any issues related to camshaft position, timing, or performance.

The scanner can also monitor live data from the engine sensors, such as the camshaft position sensor or crankshaft position sensor, to detect any abnormalities or variations.

Performance testing:

Performance testing, such as dyno testing or road testing, can help detect any changes in engine power, acceleration, fuel economy, or noise that may indicate worn cam lobes.

Performance testing can also help verify the effectiveness of the repair method after it is done.

How to prevent cam lobe pair wear?

Here are some ways to prevent cam lobe wear:

Regular oil changes:

Changing the engine oil and filter regularly can help keep the camshaft and other engine components properly lubricated and free from dirt, debris, and metal particles that can cause wear.

Proper oil viscosity and quality:

Using the recommended oil viscosity and quality for the engine and climate conditions can help ensure that the oil provides adequate lubrication and protection against wear and corrosion.

Engine break-in period:

Following the manufacturer’s recommended break-in period for a new engine or rebuilt engine can help seat the camshaft lobes and prevent premature wear.

Avoiding high-RPM operation:

Avoiding prolonged high-RPM operation or rapid acceleration and deceleration can reduce the stress on the camshaft and valve train components.

Regular maintenance and inspection:

Regular maintenance and inspection of the engine and valve train components can help detect any signs of wear or damage before they cause further problems.

This includes checking the valve lash, timing belt/chain tension, and other components that can affect the camshaft and valve train operation.

Proper valve train adjustments:

Proper valve train adjustments, such as setting the correct valve lash or rocker arm preload, can help ensure that the camshaft lobes are not subjected to excessive wear or stress.

Using quality components:

Using high-quality camshafts, lifters, rocker arms, and other valve train components that are designed for the specific engine and application can help ensure proper operation and longevity.

What kind of maintenance do you need for your engine?

Regular maintenance is essential for keeping your engine running smoothly and avoiding costly repairs. Here are some key maintenance tasks for your engine:

Oil changes:

Changing the engine oil and filter regularly ensures that the engine is properly lubricated and reduces wear on engine components.

The frequency of oil changes depends on the vehicle and driving conditions, but it’s generally recommended to change the oil every 5,000 to 7,500 miles.

Using the recommended oil viscosity and quality for the engine is important for proper lubrication and engine protection.

Air filter replacement:

The air filter prevents dirt, debris, and other contaminants from entering the engine and causing damage.

The frequency of air filter replacement depends on driving conditions and the environment, but it’s generally recommended to replace the air filter every 15,000 to 30,000 miles.

A dirty air filter can reduce engine performance and fuel economy, and can also lead to engine damage.

Spark plug replacement:

Spark plugs provide the spark needed for combustion in the engine.

The frequency of spark plug replacement depends on the vehicle and driving conditions, but it’s generally recommended to replace spark plugs every 30,000 to 100,000 miles.

Worn or fouled spark plugs can cause misfires, reduced performance, and engine damage.

Fuel filter replacement:

The fuel filter prevents contaminants from entering the fuel system and causing engine damage.

The frequency of fuel filter replacement depends on the vehicle and driving conditions, but it’s generally recommended to replace the fuel filter every 30,000 to 60,000 miles.

A clogged fuel filter can reduce fuel efficiency and cause engine damage.

Cooling system maintenance:

The cooling system keeps the engine at the proper operating temperature and prevents overheating.

Flushing and refilling the cooling system at regular intervals helps prevent corrosion, scaling, and other issues that can cause engine damage.

Checking and replacing the coolant and radiator hoses as needed is also important for preventing leaks and damage.

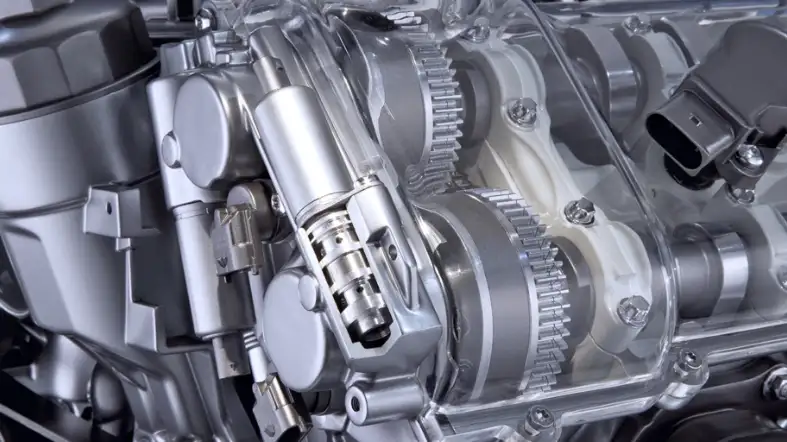

Timing belt/chain replacement:

The timing belt or chain ensures that the valves open and close at the proper time in relation to the engine’s rotation.

The frequency of timing belt/chain replacement depends on the vehicle and driving conditions, but it’s generally recommended to replace the timing belt/chain every 60,000 to 100,000 miles.

A broken or slipping timing belt/chain can cause serious engine damage.

Valve train maintenance:

The valve train includes the valves, rocker arms, and camshaft, and ensures that the engine operates properly.

Checking and adjusting the valve lash or rocker arm preload at regular intervals helps ensure proper valve operation and reduces wear on the camshaft and other components.

A worn or damaged valve train can cause engine misfires, reduced performance, and damage.

Battery maintenance:

The battery provides the electrical power needed to start the engine and operate the electrical system.

Checking the battery’s voltage and electrolyte levels regularly, and cleaning the terminals and cables as needed, helps ensure reliable starting and proper charging of the electrical system.

A weak or dead battery can cause starting issues and damage to the electrical system.

Transmission fluid and filter replacement:

The transmission fluid provides lubrication and cooling for the transmission and helps ensure smooth shifting.

Changing the transmission fluid and filter at regular intervals helps prevent transmission damage and ensure proper operation.

Low or dirty transmission fluid can cause transmission damage and shifting issues.

Brake system maintenance:

The brake system includes brake pads, rotors, calipers, and brake fluid, and ensures safe and reliable stopping.

Checking and replacing the brake components at regular intervals helps ensure proper brake performance and safety.

Worn or damaged brake components can cause brake failure and unsafe driving conditions.

FAQs

Can Worn Cam Lobes Be Repaired With A Chemical Additive?

No, there is no chemical additive that can repair worn cam lobes. Any product claiming to do so is likely a scam and may even cause further engine damage.

How Long Does It Take To Repair Worn Cam Lobes?

The time it takes to repair worn cam lobes depends on the extent of the damage and the method of repair.

Regrinding the camshaft can take several days while replacing the entire camshaft can take several hours.

Can I Drive My Car With Worn Cam Lobes?

It’s not recommended to drive a car with worn cam lobes as it can cause further engine damage and potentially lead to engine failure.

It’s best to have the issue diagnosed and repaired as soon as possible by a professional mechanic.

How Much Does It Cost To Repair Worn Cam Lobes?

The cost of repairing worn cam lobes varies depending on the extent of the damage and the method of repair.

Regrinding the camshaft can cost several hundred dollars while replacing the entire camshaft can cost several thousand dollars.

It’s best to get a quote from a professional mechanic to determine the cost of repair.

Conclusion

A worn cam lobe pair is a serious issue that can cause engine performance problems and even engine failure.

There are several ways to repair the problem, including re-grinding the camshaft, replacing the camshaft, or installing a camshaft repair kit.

Testing and monitoring the engine regularly can help detect cam lobe wear early and prevent further damage.

Proper engine maintenance, such as regular oil changes, air filter replacement, and spark plug replacement, can help prevent cam lobe wear and other engine issues.

By taking these steps and addressing worn cam lobe pairs promptly, engine owners can help ensure reliable and efficient engine performance.