As a Harley owner, you understand that regular maintenance is crucial to ensure your motorcycle runs well.

One issue that can arise is crankshaft runout, which can cause significant problems if left unaddressed.

In this article, we’ll look at what crankshaft runout is and the symptoms you should look out for.

10 Harley Crank Runout Symptoms

Here are ten common Harley crank runout symptoms:

Vibration

One of the most noticeable symptoms of crankshaft runout is excessive vibration.

This vibration can become much more pronounced if the crankshaft is bent or distorted.

You may notice the handlebars or foot pegs shaking excessively while riding, especially at higher speeds.

Engine Noise

Another symptom of crankshaft runout is increased engine noise.

If the crankshaft is bent or distorted, this movement can become uneven, causing the engine to produce more noise than usual.

You may hear knocking, rattling, or ticking sounds coming from the engine.

Reduced Engine Power

Crankshaft runout can also cause a reduction in engine power. When the crankshaft turns, it sends power to the transmission and then to the wheels.

But if the crankshaft is bent or twisted, it can lessen the amount of power that gets to the transmission.

This can make the motorcycle feel like it doesn’t have enough power and is slow to respond.

Poor Fuel Efficiency

When the crankshaft of an engine wobbles or has run out, it can harm the fuel efficiency of the engine.

The crankshaft moves the pistons up and down so that air and fuel can get into the engine and be burned.

But if the crankshaft doesn’t turn smoothly, it can mess up this process and cause the engine to use more fuel than it should.

This can make the car use more gas.

If the crankshaft is bent or twisted, this movement can become uneven, causing the engine to use more fuel than it needs to.

Premature Engine Wear

Finally, crankshaft runout can cause premature wear on other engine components.

When the crankshaft of an engine turns, it makes the connecting rods move up and down.

However, if the crankshaft has issues such as run out, it can cause extra wear on the bearings and other parts.

This is because the crankshaft’s jerky movement can cause more friction and strain on the parts, which causes them to wear out faster.

If this isn’t fixed, the engine could break down in the long run.

If the crankshaft is bent or warped, this wear can worsen and cause the engine to break down early.

Difficulty Shifting Gears

If the crankshaft is bent or distorted, it can cause difficulty shifting gears. As the crankshaft rotates, it transfers power to the transmission responsible for changing gears.

If the crankshaft is not rotating smoothly, it can make it harder to shift gears or cause the transmission to lock up.

Engine Stalling

A crankshaft runout can also cause the engine to stall. As the crankshaft rotates, it transfers power to the transmission and, ultimately to the wheels.

If the crankshaft is bent or distorted, it can cause the engine to stall or shut off completely, especially at low speeds.

Oil Leaks

Crankshaft runout can also lead to oil leaks. As the crankshaft rotates, it causes the oil to circulate through the engine.

If the crankshaft is bent or warped, engine oil can leak out, lowering oil pressure and damaging other engine parts.

Uneven Engine Idling

If the crankshaft is bent or distorted, it can cause the engine to idle unevenly.

As the crankshaft rotates, it causes the pistons to move up and down, affecting the air/fuel mixture and causing the engine to idle roughly or stall.

Overheating

A crankshaft runout can cause the engine to overheat. As the crankshaft rotates, it transfers power to the transmission and, ultimately, to the wheels.

If the crankshaft is bent or warped, the engine works harder and overheats, damaging other engine parts.

The Causes Of Harley Crank Runout

Here are some common causes of Harley Crank Runout

Improper Installation

One of the primary causes of crank runout is improper installation.

If the crankshaft isn’t installed correctly, it can become misaligned, eventually leading to a runout.

This can occur if the engine is rebuilt by an inexperienced mechanic or the parts aren’t aligned properly during assembly.

Worn Bearings

Another common cause of crank runout is worn bearings. The bearings in the engine can wear down over time, causing the crankshaft to become misaligned.

This can occur if the engine is run for an extended period without proper maintenance or if the bearings are faulty.

Bent Crankshaft

A bent crankshaft can also cause a runout.

This can occur if the engine experiences an impact, such as a crash or hard landing. Even a small bend in the crankshaft can cause it to become misaligned, leading to a runout.

Warped Flywheel

Warped flywheels can induce crank runout. Warped flywheels can misalign the crankshaft and unbalance the engine.

If the flywheel is destroyed or the engine runs at high RPMs, this can happen.

Diagnosis of Harley Crank Runout

Visual Inspection

One of the first steps in diagnosing Harley’s crank runout is visually inspecting the crankshaft.

This involves examining the crankshaft for any visible signs of damage or wear, such as cracks, scoring, or other deformities.

Any visible damage can indicate the presence of runout and may require further investigation using specialized tools.

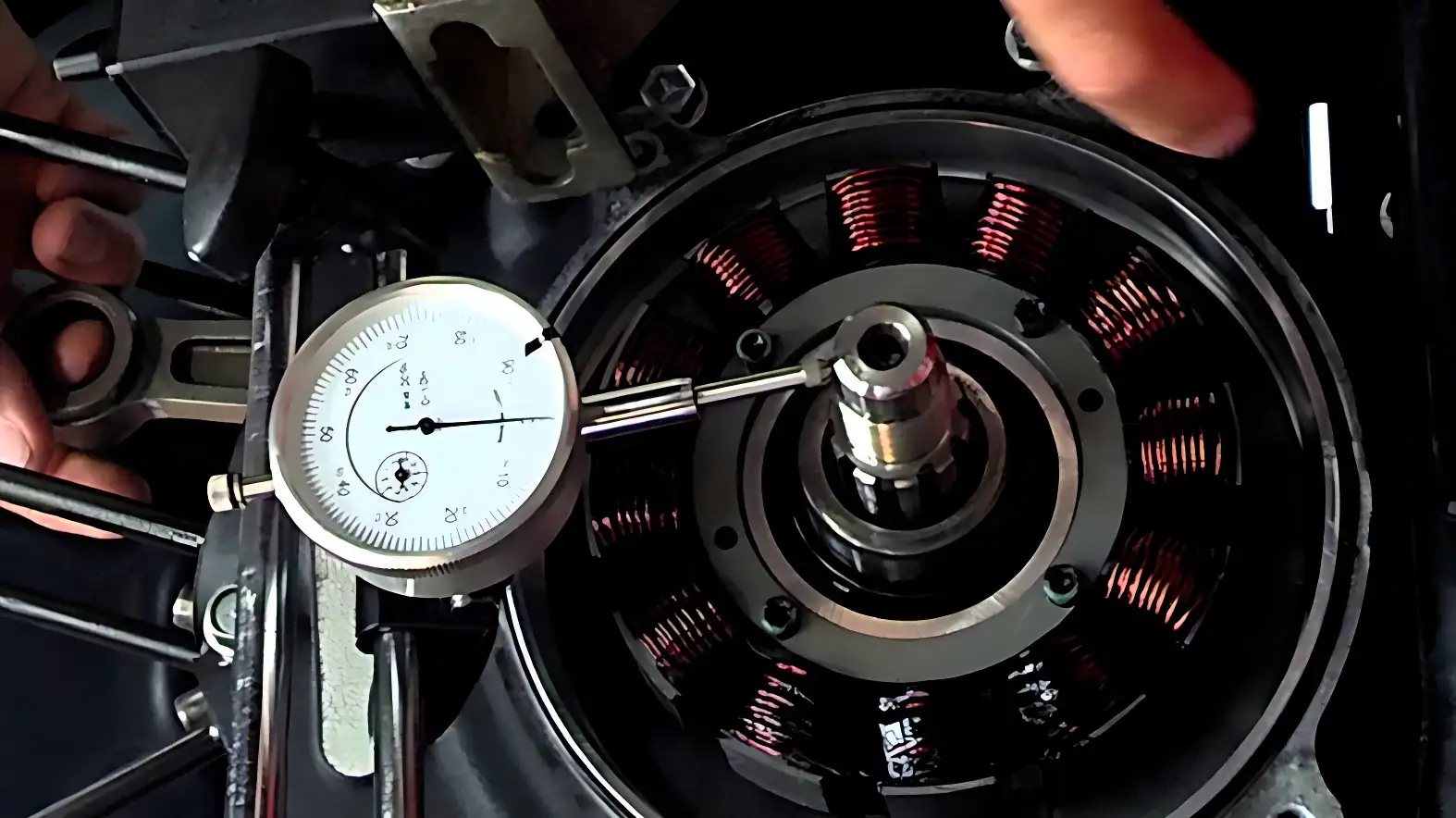

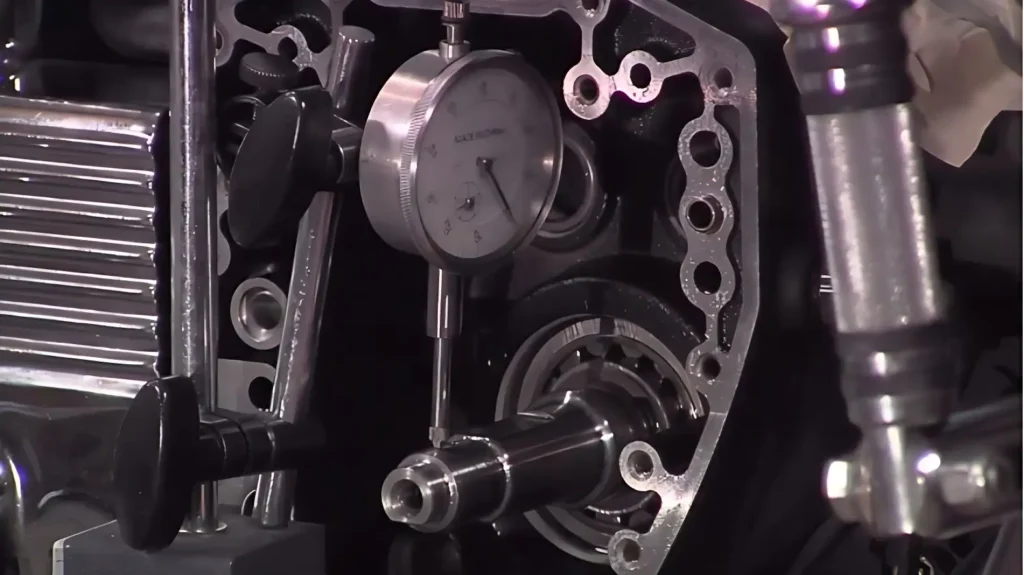

Measurements Using Dial Indicators

After the visual inspection, measurements can be taken using dial indicators.

Dial indicators are commonly used to measure the runout of the crankshaft by detecting any deviations from the expected roundness of the shaft.

This involves placing the dial indicator on the crankshaft and rotating it to detect any fluctuations in the readings.

The results of these measurements can be used to determine the extent of the runout and the location of any deviations.

Use of Specialized Equipment

Specialized equipment, such as a runout gauge or a dial bore gauge, may be used for more accurate and precise measurements.

These tools allow for a more detailed analysis of the crankshaft’s runout and can provide more specific information about the location and severity of any deviations from the expected roundness.

By using specialized equipment, technicians can determine the exact cause of the runout and develop an appropriate course of action for repair or replacement.

Harley crank runout can be treated through several methods, including:

Replacement of worn-out bearings:

Worn-out bearings can cause crankshaft runout, leading to engine problems.

Replacing these bearings with new ones can help reduce the runout and restore the engine’s performance.

Repair or replacement of connecting rods:

Worn or damaged connecting rods can also cause crankshaft runout.

Depending on the extent of damage, these rods can be repaired or replaced to ensure the engine’s smooth functioning.

Crankshaft alignment or replacement:

If the runout is too severe, the crankshaft may need to be realigned or replaced entirely.

This is a complex process that requires the expertise of a professional mechanic.

Engine rebuild or replacement:

An engine rebuild or replacement may be necessary in extreme cases where the crankshaft runout is too extensive.

This means taking the engine apart, fixing or replacing the broken parts, and putting it back together to ensure it works.

Prevention of Harley Crank Runout

Prevention of Harley Crank Runout:

Proper Engine Assembly Techniques

One of the key ways to prevent Harley crank runout is to ensure proper engine assembly techniques are used.

This includes using proper torque specifications and following the manufacturer’s guidelines for the installation of engine components.

Improper assembly can cause undue stress on the crankshaft and other engine components, leading to run out and other issues.

Regular Maintenance of Engine Components

Regular maintenance of engine components is also important in preventing crankshaft runout.

This includes regular oil changes, inspecting engine bearings, and monitoring other engine components such as camshafts and pistons.

Regular maintenance helps identify any issues before they become major problems and can help extend the engine’s life.

Timely Replacement of Worn-Out Parts

Worn-out engine components can also contribute to crankshaft runout.

It’s important to replace worn-out parts such as engine bearings, piston rings, and other components in a timely manner to prevent undue stress on the engine.

Failure to replace worn-out parts can cause additional wear on the crankshaft, leading to runouts and other issues.

Avoiding Accidents or Impacts That Can Damage the Engine

Accidents or impacts can also cause damage to the engine and contribute to a crankshaft runout.

It’s important to avoid accidents or impacts that can cause damage to the engine.

Such as avoiding collisions or other impacts that can cause undue stress on the engine.

Proper storage and handling of the motorcycle can also help prevent engine damage.

Frequently Asked Questions

Can Crankshaft Runout Cause Oil Leaks On A Harley Engine?

Yes, crankshaft runout can cause oil leaks in the engine, as it can cause the oil to leak past the seals and gaskets.

How Do I Know If My Harley’s Connecting Rods Are Damaged?

You may notice a knocking or ticking sound coming from the engine, which can be an indication of damaged connecting rods.

Can A Damaged Or Worn-Out Bearing Cause A Crankshaft Runout On A Harley Engine?

Yes, worn-out or damaged bearings can cause crankshaft runout, leading to engine problems.

Yes, worn-out or damaged bearings can cause crankshaft runout, leading to engine problems.

It is not recommended to ride your Harley with a crankshaft runout, as it can cause further damage to the engine.

Is It Possible To Fix Harley Crankshaft Runout Without Replacing The Crankshaft?

Yes, in some cases, the runout can be reduced by repairing or replacing the connecting rods and bearings.

How can I prevent a crankshaft runout on my Harley engine?

Regular engine maintenance and inspection can help prevent crankshaft runout.

Additionally, avoiding harsh riding conditions and using high-quality engine components can also help prevent this issue.

Wrap Up

By addressing this issue promptly, you can avoid more significant problems down the road, and Regular maintenance is key to keeping your Harley running smoothly, so make sure to take care of your bike to get the most out of it.