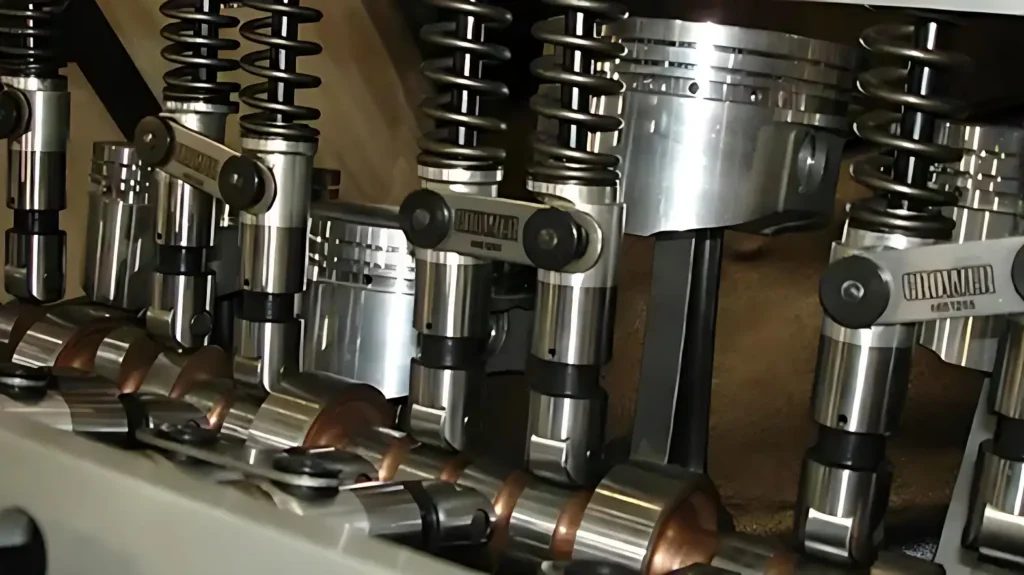

Roller rockers and hydraulic lifters are common engine components that play a crucial role in enhancing engine performance.

But can these two components be used together? The answer is yes, but there are certain things you need to know before installing roller rockers with hydraulic lifters.

In this blog, we’ll explore the benefits, compatibility considerations, installation process, and maintenance tips for using roller rockers with hydraulic lifters. Let’s dive in!

Can You Use Roller Rockers With Hydraulic Lifters?

Yes, roller rockers can be used with hydraulic lifters. They reduce friction and wear, and improve valvetrain stability and performance. Ensure that the roller rockers are compatible with your specific hydraulic lifter setup.

Here is a quick reference table to help you determine compatibility:

| Hydraulic Lifter Type | Roller Rocker Compatibility |

|---|---|

| Hydraulic Flat Tappet | Compatible |

| Hydraulic Roller | Compatible |

| Solid Flat Tappet | Not Compatible |

| Solid Roller | Not Compatible |

Benefits of Using Roller Rockers with Hydraulic Lifters

Roller rockers and hydraulic lifters are aftermarket upgrades to provide several benefits. The following are the benefits of using roller rockers with hydraulic lifters:

Reduced Friction:

Roller rockers reduce friction between the valve stem and the rocker’s arm, which can help to improve overall engine performance and efficiency.

Hydraulic lifters also help to reduce friction by providing a constant and smooth lift for the valves.

Increased Durability:

Roller rockers are more durable than traditional stamped steel rocker arms and can withstand the high forces and pressures of a high-performance engine.

When used in conjunction with hydraulic lifters, which also have a longer lifespan than solid lifters, these upgrades can help to extend the life of an engine.

Improved Valve Train Stability:

Roller rockers and hydraulic lifters work together to provide a stable and consistent lift for the valves, which can help to reduce valve float and improve valve train stability.

This can result in better overall engine performance and reduced wear on the valve train components.

Increased Power:

By reducing friction and improving valve train stability, roller rockers and hydraulic lifters can help to increase the power output of an engine.

This can be especially beneficial for high-performance engines that require maximum power and efficiency.

Choosing the Right Roller Rockers for Your Hydraulic Lifters

Here are some factors to consider when selecting roller rockers for hydraulic lifters:

Material:

Roller rockers can be made from various materials, including aluminum, steel, and titanium.

Each material has its own advantages and disadvantages in terms of durability, weight, and cost.

It is essential to choose roller rockers made from high-quality materials that are suitable for your engine’s requirements.

Ratio:

Roller rockers are available in different ratios, such as 1.5:1 and 1.6:1. The ratio refers to the amount of valve lift that is achieved for every unit of camshaft lift.

It is essential to choose the right ratio based on your engine’s requirements and the camshaft you are using.

Design:

Roller rockers are available in various designs, including full roller, roller tip, and needle-bearing.

Each design has its own advantages and disadvantages in terms of performance, cost, and complexity.

It is important to choose a design that is suitable for your engine’s requirements and budget.

Brand and Quality:

Roller rockers are available from various brands and manufacturers, and the quality can vary significantly.

It is essential to choose a reputable brand that has a proven track record of producing high-quality roller rockers that are suitable for your engine’s requirements.

Installation:

Roller rockers can be challenging to install correctly, and it is essential to follow the manufacturer’s instructions carefully.

Ensure that the roller rockers are properly lubricated and torqued to the correct specifications to prevent damage to the engine.

Installation Process for Roller Rockers and Hydraulic Lifters

Here’s a comprehensive guide on how to install roller rockers and hydraulic lifters.

Tools You’ll Need:

Before starting, make sure you have the following tools:

- Torque wrench

- Wrench set

- Screwdriver

- Rocker arm removal tool

- Hydraulic lifter removal tool

- Gasket scraper

- Lubricant

Step 1: Remove the Old Rocker Arms

To begin, remove the valve covers and locate the rocker’s arms. Then, use a rocker arm removal tool to remove the old rocker arms.

Make sure to keep the rocker arms in order to reinstall them correctly later.

Step 2: Install the Roller Rockers

Install the roller rockers in the same order as the old rocker arms. Make sure to follow the manufacturer’s instructions for proper installation torque specifications.

Use a torque wrench to ensure that the bolts are tightened to the correct torque settings.

Step 3: Install the Hydraulic Lifters

Remove the old hydraulic lifters using a lifter removal tool. Then, install the new hydraulic lifters in the same location as the old ones.

Make sure to use a lubricant on the lifters before installation.

Step 4: Install the Pushrods and Adjust the Valve Lash

Install the pushrods and adjust the valve lash according to the manufacturer’s specifications.

Make sure to follow the recommended torque settings when tightening the bolts.

Step 5: Reinstall the Valve Covers

Reinstall the valve covers and start the engine to ensure that everything is running smoothly. Check for any oil leaks or unusual noises.

Potential Issues to Look Out for When Using Roller Rockers with Hydraulic Lifters

When using roller rockers with hydraulic lifters, there are a few potential issues that you should be aware of. Here are some of the most common issues to look out for

Incorrect rocker arm ratio:

If the rocker arm ratio is incorrect, it can cause excessive valve lift, leading to valve float or even contact between the valve and piston.

Make sure to use the recommended rocker arm ratio for your engine.

Poor valve train geometry:

Poor valve train geometry can cause uneven valve lift, leading to excessive wear on the valve stems and guides.

This can also cause valve float or contact between the valve and piston. Check the valve train geometry and adjust it.

Improper lifter preload:

If the lifter preload is incorrect, it can cause noise or excessive wear on the lifters. Make sure to follow the manufacturer’s instructions for proper lifter preload.

Insufficient oiling:

Roller rockers require more oil than stock rocker arms. If the oiling system is insufficient, it can cause premature wear on the rockers and lifters.

Make sure to use an oiling system that is designed for roller rockers.

Valve cover clearance:

Roller rockers are generally taller than stock rocker arms, which can cause clearance issues with the valve covers.

Make sure to use valve covers that are designed to accommodate roller rockers.

Maintenance Tips for Roller Rockers and Hydraulic Lifters

Roller rockers and hydraulic lifters are essential components in high-performance engines.

To ensure that they perform optimally and last longer, here are some maintenance tips to follow:

Regular Inspection:

Regularly inspect the roller rockers and hydraulic lifters for signs of wear, damage, or excessive play.

Look for any abnormal wear patterns, such as flat spots or galling, which can indicate problems with the valve train geometry or insufficient oiling.

Lubrication:

Roller rockers require more lubrication than stock rocker arms. Make sure to use high-quality engine oil that is formulated for high-performance engines.

Also, consider using an oiling system that is specifically designed for roller rockers.

Adjust Valve Lash:

Make sure to adjust the valve lash according to the manufacturer’s specifications.

A proper valve lash adjustment ensures that the hydraulic lifters operate correctly and prevents valve float or excessive wear on the valve stems and guides.

Proper Installation Torque:

Follow the manufacturer’s instructions for proper installation torque specifications when installing roller rockers and hydraulic lifters.

Using the wrong torque settings can cause damage to the components and affect the engine’s performance.

Use Quality Components:

Use high-quality roller rockers and hydraulic lifters that are designed for your engine.

Avoid using low-quality or generic components, which may not provide the same level of performance or reliability.

FAQs

Do Roller Rockers And Hydraulic Lifters Require Special Maintenance?

Yes, roller rockers and hydraulic lifters require proper maintenance to ensure optimal performance and longevity.

This includes regular inspection for signs of wear or damage, proper lubrication, and following the manufacturer’s instructions for valve lash adjustment and installation torque specifications.

Can Roller Rockers And Hydraulic Lifters Be Used With Any Type Of Engine?

Roller rockers and hydraulic lifters can be used with most types of engines, but it’s essential to choose components that are designed for your specific engine.

Make sure to follow the manufacturer’s recommendations and specifications when choosing and installing roller rockers and hydraulic lifters.

What Are Some Potential Issues To Watch Out For When Using Roller Rockers With Hydraulic Lifters?

Some potential issues to watch out for include incorrect rocker arm ratio, poor valve train geometry, improper lifter preload, insufficient oiling, and valve cover clearance issues.

Regular inspections and proper maintenance can help detect and prevent these issues.

Conclusion:

Roller rockers and hydraulic lifters can be used together to improve engine performance and efficiency.

Choose high-quality components that are designed for your specific engine and follow the manufacturer’s instructions for proper installation and maintenance.

With regular inspections and proper maintenance, roller rockers and hydraulic lifters can provide long-lasting benefits for your engine.