Are you looking to upgrade your engine’s performance but unsure about compatibility between your roller lifters and hydraulic cam?

The debate over whether to use roller lifters on hydraulic cams has been ongoing, and it can be confusing for anyone trying to modify their engine.

In this blog post, we’ll dive into the technicalities of roller lifters and hydraulic cams, and discuss whether they can work together to boost your engine’s performance.

Can You Use Roller Lifters On A Hydraulic Cam?

Yes, you can use roller lifters on a hydraulic cam. Roller lifters reduce friction and wear, allowing for higher engine speeds and improved performance. However, proper selection and compatibility with the camshaft is crucial for optimal operation.

There are some factors to consider, such as compatibility with other engine components and the higher cost compared to flat tappet lifters.

The following table summarizes the pros and cons of using roller lifters on a hydraulic cam:

| Pros | Cons |

|---|---|

| Improved performance | Higher cost |

| Increased durability | Compatibility issues |

| Reduced wear and tear | Increased complexity |

What are the Benefits of Using Roller Lifters on a Hydraulic Cam?

Roller lifters on a hydraulic cam can offer several benefits compared to flat tappet cam and lifters. Some of these benefits include:

Improved performance:

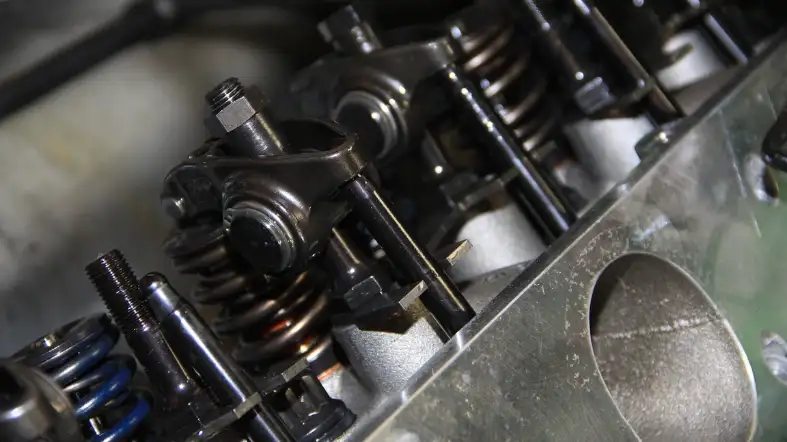

Roller lifters have a roller bearing on the end that comes in contact with the camshaft lobe, which reduces friction and wear.

Reduced friction leads to improved valvetrain stability, which allows for higher RPMs and improved performance.

Roller lifters are also designed to handle higher spring pressures, which can improve valve control and overall engine performance.

Increased durability:

Roller lifters are typically made of higher-quality materials than traditional flat tappet lifters, which can make them more durable and resistant to wear.

The roller bearing design distributes the load more evenly across the lifter and camshaft surfaces, which can reduce wear and damage to these components over time.

The reduced wear and tear on the engine components can lead to a longer overall engine lifespan.

Reduced wear and tear:

The roller bearing design of roller lifters provides better contact between the lifter and camshaft surfaces, which can reduce wear and tear on these components.

The more even load distribution across the surfaces of the lifter and camshaft can also reduce the risk of galling, scoring, or other types of damage that can occur with traditional lifters.

The reduced wear and tear can also lead to lower maintenance costs over time.

Quieter operation:

Roller lifters produce less noise than traditional flat tappet lifters due to the roller bearing design.

The reduced noise can lead to a quieter and smoother engine operation.

Longer service life:

The improved durability and reduced wear and tear on engine components can lead to longer service life for the engine.

Roller lifters typically require less frequent replacement than traditional lifters, which can lead to cost savings over time.

The longer service life can also lead to the increased resale value of the vehicle.

What are the Drawbacks of Using Roller Lifters on a Hydraulic Cam?

While roller lifters on a hydraulic cam offer several benefits, there are also some potential drawbacks to consider:

Increased Cost:

Roller lifters are generally more expensive than flat tappet lifters.

In addition to the cost of the lifters themselves, using roller lifters may require additional components to be used in the valve train, such as pushrods and rocker’s arms, which can further increase the cost of the engine build.

Compatibility Issues:

Roller lifters may not be compatible with all cylinder heads or engine blocks.

For example, some engine blocks may not have enough clearance to accommodate roller lifters.

It’s important to ensure that the roller lifters are compatible with the specific engine build before installation.

Potential for Lifter Failure:

While roller lifters are generally more durable than flat tappet lifters, they can still fail.

If a roller lifter fails, it can cause damage to the camshaft and other engine components.

In addition, the use of roller lifters may require more frequent oil changes and maintenance to ensure that the lifters are functioning properly.

Increased Complexity:

The use of roller lifters on a hydraulic cam can increase the complexity of the engine build and maintenance.

Roller lifters require more precise installation and adjustment than flat tappet lifters.

In addition, the use of roller lifters may require different components to be used in the valve train, which can further increase the complexity of the build.

Noise and Vibration:

While roller lifters can reduce valve train noise compared to flat tappet lifters, they can also produce a different type of noise and vibration.

This is because the roller bearing in the lifter can produce a slight clicking sound as it rolls over the cam lobe.

Some engine builders and enthusiasts prefer the traditional sound of flat tappet lifters over the sound of roller lifters.

How to Choose the Right Roller Lifters for Your Hydraulic Cam

Choosing the right roller lifters for your hydraulic cam is important to ensure proper engine performance and longevity. Here are some factors to consider:

Compatibility:

Make sure the roller lifters you choose are compatible with your specific hydraulic camshaft.

Not all roller lifters are designed to work with all camshafts, so check with the manufacturer or consult with an engine builder to ensure compatibility.

Type of roller lifter:

There are two main types of roller lifters – hydraulic and solid.

Hydraulic roller lifters are designed to operate with a hydraulic camshaft and are typically easier to install and maintain.

Solid roller lifters are designed for use with a solid camshaft and are often used in high-performance engines.

Materials:

Look for roller lifters made from high-quality materials that can handle the stresses of high-performance engines.

Some high-end roller lifters are made from materials like billet steel or titanium for added strength and durability.

Brand reputation:

Choose roller lifters from a reputable brand with a proven track record of producing quality engine components.

Avoid purchasing cheap or low-quality roller lifters, as they may not perform as well or have the same level of durability as higher-end options.

Budget:

Roller lifters can range in price from a few hundred dollars to several thousand dollars.

Consider your budget and choose roller lifters that fit within your price range, while still providing the necessary level of performance and durability for your engine.

FAQs

Can Roller Lifters Be Used With Hydraulic Cams?

Yes, roller lifters can be used with hydraulic cams.

In fact, many high-performance engines use hydraulic roller lifters to improve engine performance and durability.

Can I Install Roller Lifters On My Engine Myself Or Do I Need A Professional Mechanic?

While it’s possible to install roller lifters on your engine yourself, it’s recommended to have a professional mechanic perform the installation to ensure proper fit and function.

Are Roller Lifters More Expensive Than Traditional Lifters?

Roller lifters can be more expensive than traditional lifters, especially for high-end, performance-grade options.

The added durability and improved engine performance can make the investment worth it.

Can Using Roller Lifters With A Hydraulic Cam Improve Engine Performance?

Yes, using roller lifters with a hydraulic cam can improve engine performance by providing better valve timing and lift, reduced friction and wear, and improved overall engine efficiency.

Conclusion

Using roller lifters on a hydraulic cam can provide many benefits, such as increased durability, reduced friction, and improved performance.

It’s important to choose the right roller lifters for your specific hydraulic camshaft to ensure compatibility and optimal performance.

Consider factors like compatibility, type of roller lifter, materials, brand reputation, and budget when selecting roller lifters for your engine.

With the right combination of roller lifters and hydraulic cam, you can enjoy a powerful and reliable engine for years to come.