The size of the bolts is one such factor and must be chosen carefully for proper installation.

It all depends on your car’s make and model – while some might furthermore, buy high-quality hardware that has been tested by experts and certified under industry standards; this will help ensure optimal performance from your new setup down the line too.

Keep reading to learn more about what size bolts are for catalytic converters.

What Size Bolts For Catalytic Converter?

The size of bolts necessary for a catalytic converter can depend on the make and model of your car.

Whether you’re driving an old beater or a brand-new sportscar, the right bolt specs will ensure your ride runs smoothly.

It is important to consult your vehicle’s owner’s manual or a trusted mechanic to determine the appropriate size of bolts required for your specific catalytic converter.

Generally, bolts used for catalytic converters are M8 or M12 in size and come in varying lengths.

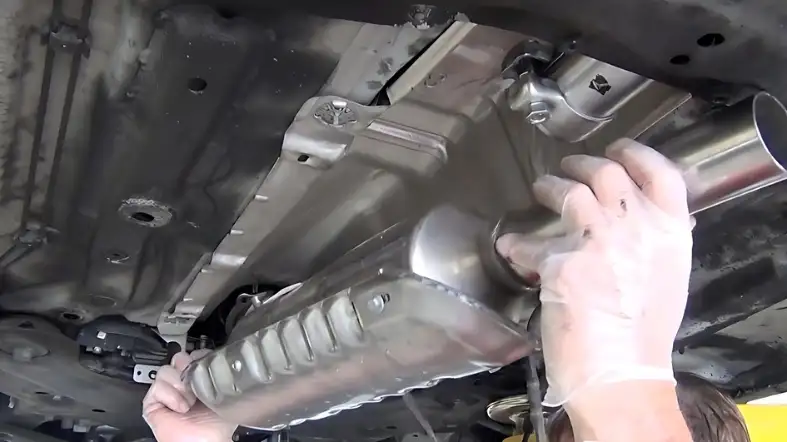

When it comes to installing a new catalytic converter, replacing the bolts and nuts is essential for proper fit and functionality.

Upgrading to top-notch hardware can make all the difference when looking for reliable performance on the road.

By investing in quality materials upfront, you’ll ensure a safe installation without any surprises.

Additionally, it is important to torque the bolts to the manufacturer’s specifications to prevent damage to the converter or exhaust system.

How Do You Determine The Correct Size Bolts For A Catalytic Converter?

Consult the vehicle owner’s manual:

The vehicle owner’s manual is the first place to look when determining the correct size bolts for a catalytic converter.

This manual should include all the necessary details about a particular make and model of vehicle, like what size and kind of bolts are required for the catalytic converter.

The vehicle manufacturer’s website may also have this information if the manual is unavailable.

Look up the bolt size online:

Many automotive forums, websites, and resources provide information on bolt sizes for specific vehicles.

Measure the bolt diameter and length:

Measuring the bolt diameter and length can be done quickly, even if your manual or online resources don’t have the info you need.

Grab a caliper or ruler, look at the bolts already in use, or measure up those holes in your catalytic converter’s flange – it’ll only take seconds.

This will provide an accurate measurement of the required bolt size.

Ask a mechanic or automotive expert:

If all other methods fail, consulting with a mechanic or automotive expert may be necessary.

These professionals have experience working with a variety of vehicles and may know the correct bolt size for a specific make and model.

Additionally, they may have specialized tools or resources that can be used to determine the correct size bolts for a catalytic converter.

What materials are used to make catalytic converter bolts?

Steel:

Steel is a common material used to make catalytic converter bolts. It is durable, strong, and can withstand high temperatures.

Steel bolts are often coated with a protective layer to prevent rust and corrosion.

Stainless Steel:

Stainless steel is another popular material used for catalytic converter bolts. It has excellent corrosion resistance and can withstand high temperatures.

Additionally, stainless steel bolts are easy to clean and maintain.

Titanium:

Titanium is a lightweight and strong material that is commonly used in high-performance applications.

It is often used for catalytic converter bolts in racing and performance vehicles.

Titanium bolts are more expensive than other materials but offer superior strength and durability.

Inconel:

Inconel is a high-performance alloy that is often used in extreme environments, such as aerospace and marine applications.

Inconel bolts are strong, corrosion-resistant, and can withstand high temperatures.

Nickel:

Nickel is another material used for catalytic converter bolts. It has good resistance to corrosion and can withstand high temperatures.

Nickel bolts are often used in industrial and high-performance applications requiring strength and durability.

What are the different types of catalytic converter bolts?

Standard Bolts

Standard bolts are the go-to fastening choice for attaching a catalytic converter to any vehicle’s exhaust system.

With sizes and materials ranging from steel and stainless steel to titanium – there’s an option that fits the bill.

They typically require a wrench or socket to tighten, and their length and thread pitch can vary depending on the specific application.

The bolt size for a catalytic converter should be between M10 and M25x25, with a thread pitch of 12-14mm X 1.5M (metric)

U-Bolts

U-bolts are another type of bolt that can attach a catalytic converter to a vehicle’s exhaust system.

These bolts are shaped like a U and are designed to fit around the exhaust pipe and the converter.

They typically require nuts to secure them in place and can be tightened using a wrench or socket.

Studs and Nuts

Studs and nuts are other options for attaching a catalytic converter to a vehicle’s exhaust system.

Studs are threaded rods that are inserted through holes in the exhaust pipe and the converter and then secured in place using nuts.

This can make installation easier, especially if the converter is inaccessible. Studs and nuts are available in various sizes and materials.

Can You Reuse Bolts When Replacing A Catalytic Converter?

In general, it is not recommended to reuse bolts when replacing a catalytic converter.

This is because the bolts may have weakened or damaged over time due to exposure to heat, vibration, and other environmental factors.

Additionally, the threads on the bolts may have become damaged, which can lead to issues with proper installation and torque specifications.

It is important to use new bolts that are specifically designed for the make and model of the vehicle and that meet the torque specifications required for the new catalytic converter installation.

Using the wrong size or type of bolt can lead to issues with the installation, including leaks, vibration, and other problems.

In some cases, it may be possible to reuse bolts if they are in good condition and meet the torque specifications required for the new catalytic converter installation.

What Torque Specifications Should Be Used When Tightening Catalytic Converter Bolts?

Manufacturer’s documentation

The manufacturer’s documentation for the vehicle should provide the torque specifications for tightening the catalytic converter bolts.

This documentation can typically be found in the vehicle owner’s manual or service manual.

Online resources

Various online resources provide torque specifications for catalytic converter bolts.

For example, a forum post on Toyotanation.com provides torque values of 440 Nm (32 ft-lb, 43 Nm) for the nuts/bolts holding the catalytic converter to the front pipe and to the center exhaust pipe.

Another source, a torque specification sheet on JustAnswer.com, lists torque values of 15 Nm (20 ft-lb) for the right catalytic converter heat shield bolt and 30 Nm (41 ft-lb) for the right exhaust manifold-to-right catalytic converter flange bolt

Torque-tension relationship

It is important to keep in mind that torque is only an indirect indication of tension, and no two bolts respond exactly the same to a given torque.

Over or under-tightening of fasteners can result in costly equipment failure and/or personal injury.

Therefore, extreme caution should be used when using a formula for torque/tension relationships.

Using a calibrated torque wrench is recommended to ensure accurate torque values and prevent over-tightening of bolts.

Torque wrench options

There are several options for torque wrenches available on the market.

For example, Park Tool offers two styles of beam-type torque wrenches that use a 3/8″ square drive to accept standard 3/8″ bits.

Selecting the correct torque wrench for the specific application and referring to the manufacturer’s documentation or reliable sources for torque specifications is important.

Frequently Asked Question

Q. Do I Need To Replace The Bolts When Replacing The Catalytic Converter?

A: It is generally recommended to use new bolts when replacing the catalytic converter.

This is because the old bolts may have become weakened or damaged over time due to exposure to heat and vibration and may not provide the necessary strength and stability for the new installation.

Q. How Do I Determine The Correct Size Bolts For My Catalytic Converter?

A: You can determine the correct size bolts for your catalytic converter by consulting the vehicle owner’s manual, looking up the bolt size online, measuring the bolt diameter and length, or asking a mechanic or automotive expert.

Q. What Material Are Catalytic Converter Bolts Typically Made Of?

A: Catalytic converter bolts are typically made of materials that can withstand high temperatures and resist corrosion, such as steel, stainless steel, titanium, Inconel, and nickel.

Q. What Is The Torque Specification For Catalytic Converter Bolts?

A: The torque specification for catalytic converter bolts can vary depending on the make and model of the vehicle.

It is important to consult the vehicle owner’s manual or ask a mechanic or automotive expert for the correct torque specification for your specific installation.

Conclusion:

By consulting the vehicle owner’s manual, measuring the bolt diameter and length, or seeking the advice of a mechanic or automotive expert, you can determine the correct size bolts for your specific catalytic converter installation.