If your vehicle won’t start and you suspect the crankshaft position sensor may be the culprit, resetting it could be a simple solution.

This sensor is responsible for detecting the position of the crankshaft to initiate fuel injection and ignition.

In this article, we’ll go over the basic steps for resetting the crankshaft position sensor and getting your vehicle running again.

How to reset a Crankshaft Position Sensor with no start

If you’re suspecting any problem with the crankshaft position sensor, follow the below steps.

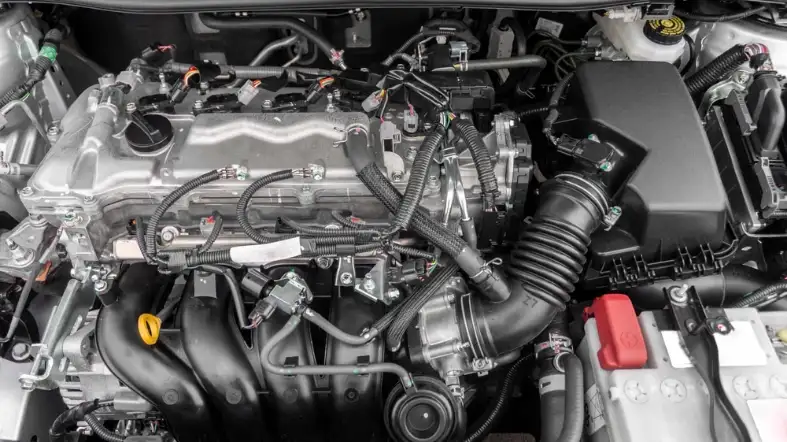

Step 1: Locate the Crankshaft Position Sensor

The first step in resetting the crankshaft position sensor is to locate it.

Typically, it is located near the engine’s crankshaft and is a small, rectangular-shaped sensor.

Check the owner’s manual or online resources if you’re having difficulty locating it.

Step 2: Disconnect the Battery

Before proceeding with the reset, you should always disconnect the battery.

This is a safety measure that prevents any electrical mishaps from occurring. Locate the battery and disconnect the negative terminal.

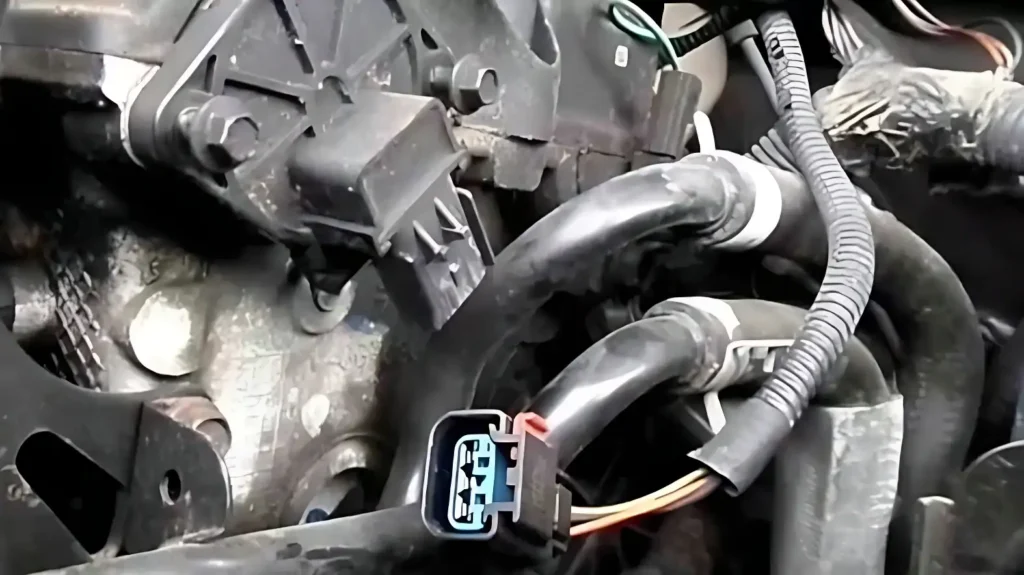

Step 3: Remove the Sensor Connector

The sensor connector is a small plastic piece that connects the sensor to the vehicle’s electrical system.

Gently remove it and inspect it for any signs of damage. If it’s damaged, replace it before proceeding.

Step 4: Wait for 10-15 Minutes

After disconnecting the sensor connector, wait for 10-15 minutes before reconnecting it.

This allows the electrical system to reset and ensures a more accurate reading from the sensor.

Step 5: Reconnect the Sensor Connector

Once the waiting time has passed, reconnect the sensor connector. Make sure it’s securely fastened to avoid any electrical issues.

Step 6: Reconnect the Battery

After reconnecting the sensor connector, reconnect the battery. Connect the negative terminal first, followed by the positive terminal.

Turn the ignition on and check if the engine starts up.

Step 7: Test Drive the Vehicle

If the engine starts up, take the vehicle for a test drive. Monitor the vehicle’s performance to ensure that the reset was successful.

If the engine doesn’t start up, repeat the steps or seek professional help.

Symptoms of a Faulty Crankshaft Position Sensor

When the sensor is faulty, it can cause a range of problems. Here are some common symptoms of a faulty crankshaft position sensor:

Engine Stalling or Misfiring

A faulty crankshaft position sensor can cause the engine to stall or misfire while running.

The sensor provides the ECM with information on the position of the crankshaft. If the sensor is malfunctioning, the ECM is not able to adjust the timing correctly.

Difficulty Starting the Engine

If the crankshaft position sensor is failing, it may cause difficulty in starting the engine.

The sensor provides the ECM with the position of the crankshaft, which is used to determine when to fire the spark plugs and inject fuel.

If the sensor is not providing the correct information, the engine may not start or may take longer to start than usual.

Reduced Engine Power

A faulty crankshaft position sensor can cause a reduction in engine power. This is because the ECM relies on the information from the sensor to determine the correct timing for fuel injection and ignition.

If the timing is incorrect, the engine may not produce enough power to operate efficiently.

Poor Fuel Economy

A malfunctioning crankshaft position sensor can cause poor fuel economy.

The sensor provides the ECM with information on the position of the crankshaft, which is used to adjust the fuel injection timing.

If the timing is incorrect, the engine may consume more fuel than necessary, resulting in reduced fuel economy.

Check Engine Light

A faulty crankshaft position sensor can trigger the check engine light to come on.

The ECM uses the information from the sensor to adjust engine timing and fuel injection.

If the sensor is malfunctioning, the ECM may detect a problem and trigger the check engine light to come on.

Step-by-Step Guide to Resetting a Crankshaft Position Sensor

If you are experiencing problems with your vehicle’s engine and suspect that the crankshaft position sensor is to blame, you may be able to reset the sensor yourself.

Here’s a step-by-step guide on how to reset a crankshaft position sensor:

Disconnect the Battery

Before resetting the crankshaft position sensor, it’s important to disconnect the battery to avoid any electrical shock or damage to the electrical system.

Locate the battery and use a wrench to loosen the negative cable clamp. Then, remove the negative cable from the battery and secure it away from the battery terminal.

Locate the Crankshaft Position Sensor

The crankshaft position sensor is usually located near the crankshaft or flywheel, depending on the make and model of your vehicle.

Consult your vehicle’s owner manual or repair manual to locate the sensor.

Remove the Sensor Connector

Once you’ve located the crankshaft position sensor, you’ll need to remove the sensor connector. The connector is usually secured with a clip or bolt.

Use a wrench or screwdriver to remove the clip or bolt and gently pull the connector away from the sensor.

Reconnect the Sensor Connector

After removing the sensor connector, wait for a few minutes before reconnecting it. This will allow the electrical system to reset.

Gently push the connector back onto the sensor until you hear a clicking sound. Make sure the connector is secure and in the correct position.

Reconnect the Battery

Once the sensor connector is securely in place, it’s time to reconnect the battery.

Replace the negative cable on the battery terminal and use a wrench to tighten the cable clamp.

Be careful not to over-tighten the clamp as this can damage the battery terminal.

Start the Engine

With the battery reconnected, start the engine and check to see if the problem has been resolved.

If the engine starts and runs smoothly, the crankshaft position sensor has been successfully reset.

If the problem persists, it’s best to consult a qualified mechanic for further diagnosis and repair.

Common Mistakes to Avoid When Resetting a Crankshaft Position Sensor

Some common mistakes can lead to further problems with your vehicle’s engine, like:

Failing to Disconnect the Battery

Not disconnecting the battery:

Before attempting to reset the crankshaft position sensor, it’s important to disconnect the battery to avoid electrical shock or damage to the vehicle’s electrical system.

Failing to identify the sensor location:

Before removing the sensor connector, it’s essential to identify the sensor’s location and make sure you are disconnecting the correct sensor.

Not waiting long enough:

After disconnecting the sensor connector, it’s important to wait a few minutes before reconnecting it. This allows the sensor to reset properly.

Using the wrong tools:

Use the correct tools for the job, such as a socket wrench or pliers to remove the connector, and a multimeter to test the sensor.

Forgetting to test the sensor:

After resetting the sensor, test it with a multimeter to function properly. Skipping this step can lead to further issues with the engine.

Not addressing the underlying issue:

Resetting the crankshaft position sensor may fix the issue temporarily, but if there are underlying problems with the engine or electrical system, the issue will likely return.

Rushing the process:

Take your time when resetting the crankshaft position sensor to avoid making mistakes or causing damage to the vehicle.

Rushing the process can lead to further issues with the engine or electrical system.

Ignoring warning signs:

If your vehicle is experiencing issues such as engine stalling, rough idling, or poor acceleration, address the issue promptly rather than wait for it.

Ignoring warning signs can lead to more costly repairs down the line.

When to Replace a Crankshaft Position Sensor

If the sensor fails or malfunctions, it can cause a range of problems, including engine stalling, rough idling, and poor acceleration.

Here are some signs that your crankshaft position sensor may need to be replaced:

Check Engine Light

One of the most common signs of a faulty crankshaft position sensor is an illuminated check engine light on your vehicle’s dashboard.

This can indicate a range of issues, including a malfunctioning sensor.

Engine Stalling or Misfiring

A malfunctioning crankshaft position sensor can cause the engine to stall or misfire.

If you notice the engine is stalling or misfiring regularly, even after resetting the sensor, it needs to be replaced.

Rough Idling

If your engine is idling roughly or inconsistently, it can be a sign that the crankshaft position sensor is malfunctioning.

This can cause your vehicle to vibrate or shake when idling, and it may even stall.

Poor Acceleration

Experiencing poor acceleration or difficulty starting your vehicle, can be a sign of improper crankshaft sensor position.

This can cause the engine’s struggle of running or can take longer than usual to reach high speeds.

Reduced Gas Mileage

A faulty crankshaft position sensor can also lead to reduced gas mileage.

This is because the sensor is responsible for ensuring that the engine is running efficiently.

Malfunctioning can cause the engine to consume more fuel than necessary in reducing gas mileage.

FAQs

Can Resetting The Crankshaft Position Sensor Fix A No Start Issue?

Resetting the crankshaft position sensor can fix a no start issue if the problem is caused by a malfunctioning sensor.

If there are other issues with the engine or electrical system, resetting the sensor may not solve the problem.

What Should I Do If Resetting The Crankshaft Position Sensor Doesn’t Fix The Issue?

If resetting the crankshaft position sensor doesn’t fix the issue, inspected it by a qualified mechanic.

They can diagnose the problem and recommend the necessary repairs.

How Often Should I Reset The Crankshaft Position Sensor?

You should only reset the crankshaft position sensor if you are experiencing issues with your engine, such as engine stalling, rough idling, or poor acceleration.

It is not necessary to reset the sensor regularly.

Is It Safe To Reset The Crankshaft Position Sensor Myself?

Yes, it is safe to reset the crankshaft position sensor yourself as long as you follow the correct procedures and avoid common mistakes. Consult a qualified mechanic for assistance.

Conclusion

Resetting the crankshaft position sensor can be a simple and cost-effective solution to fix a “no start” issue in your vehicle.

Follow the proper steps and avoid common mistakes to ensure that the sensor is reset correctly and functioning properly.

If you are not sure about resetting the sensor, consult a professional mechanic to avoid causing further damage to your vehicle.